Concentric polymer allocator

A technology of distributing device and main body, applied in the field of concentric distributing aggregator, can solve the problems of affecting the normal injection of other layers, low docking success rate, high labor intensity, etc., achieving high docking success rate, short measurement and adjustment period, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

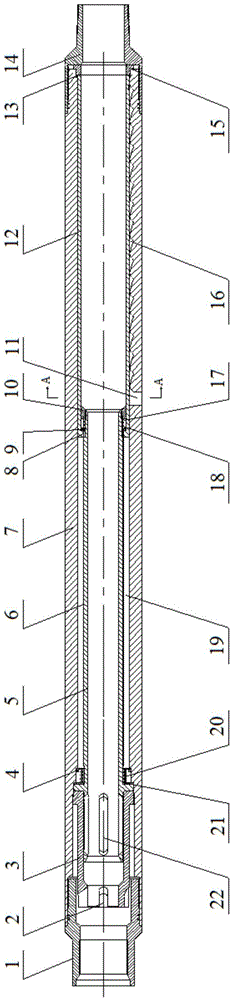

[0028] The embodiment of the present invention provides a concentric agglomerator to solve the technical problems of the eccentric agglomerator, such as low butt joint success rate, long test period, high labor intensity and affecting normal polymer injection in other layers.

[0029] An embodiment of the present invention provides a concentric coordinator, including:

[0030] upper connector;

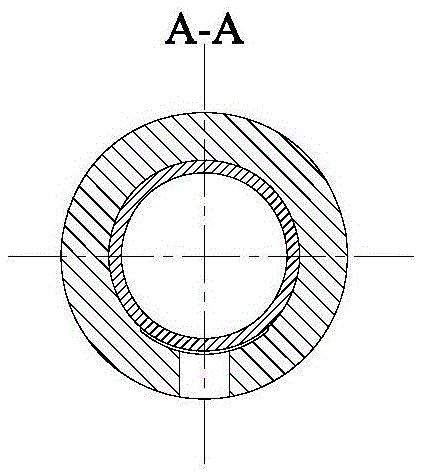

[0031] The main body is connected with the upper joint. The main body has an accommodating space, and a stepped structure is arranged in the accommodating space. The inner wall of the main body away from the upper joint is provided with a shuttle-shaped groove, and the end of the shuttle-shaped groove close to the upper joint is provided with a liquid outlet. , the liquid outlet is connected to the outside of the accommodation space;

[0032] The positioning platform is arranged in the accommodation space and connected with the main body;

[0033] The valve core is set in the accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com