Model learning method applicable to cross rolling

A technology of learning methods and models, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of unstable rolling and low product quality accuracy, and achieve increased stability, reduced accident losses, and improved quality. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The traditional Mitsubishi model learning method is based on the actual data of the last rolling steel of this specification. The consideration factors are relatively simple, and the rolling conditions at that time are not fully considered, so the learning effect is not ideal.

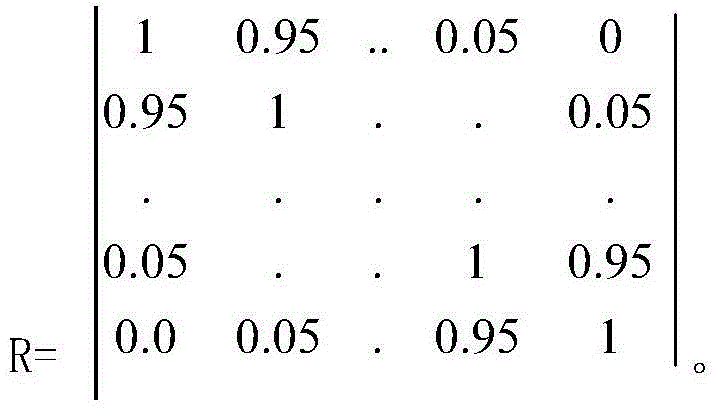

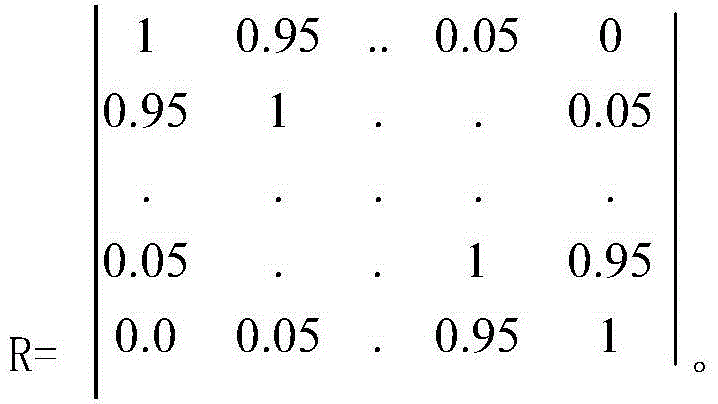

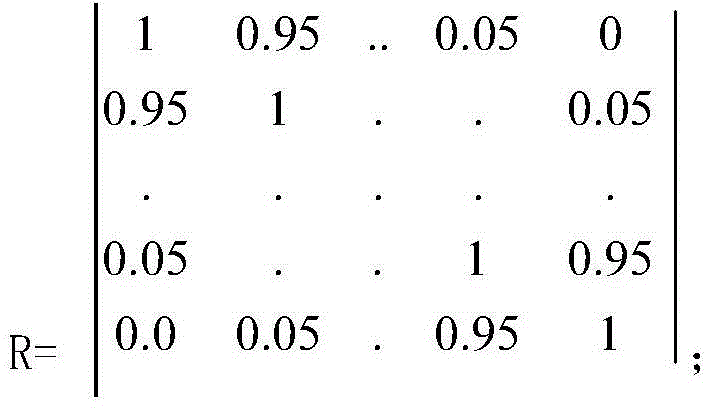

[0016] The present invention uses fuzzy mathematical method to carry out cluster analysis and classification to the steel grades rolled before and after, adopts fuzzy distribution method to obtain its membership function, establishes fuzzy matrix, determines its similarity degree according to fuzzy matrix value, and finally determines its learning inheritance Degree.

[0017] Concrete method and steps of the present invention are:

[0018] 1. Determine the fuzzy set: define the universe of fuzzy set U as at least 18 types of previously rolled steel by mathematical methods, open up a cache in the system memory, store the data of at least 18 types of rolled steel and update it at any time, and est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com