Shell connecting structure

A technology for connecting structures and shells, which is applied in the direction of shells, instrument parts, instruments, etc., to achieve the effects of simple structure, convenient installation, and prevention of disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

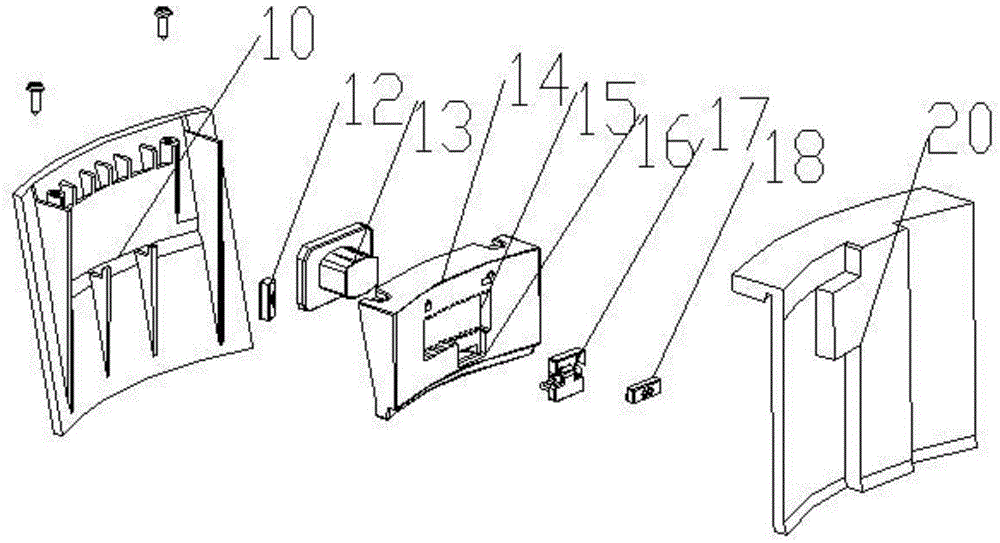

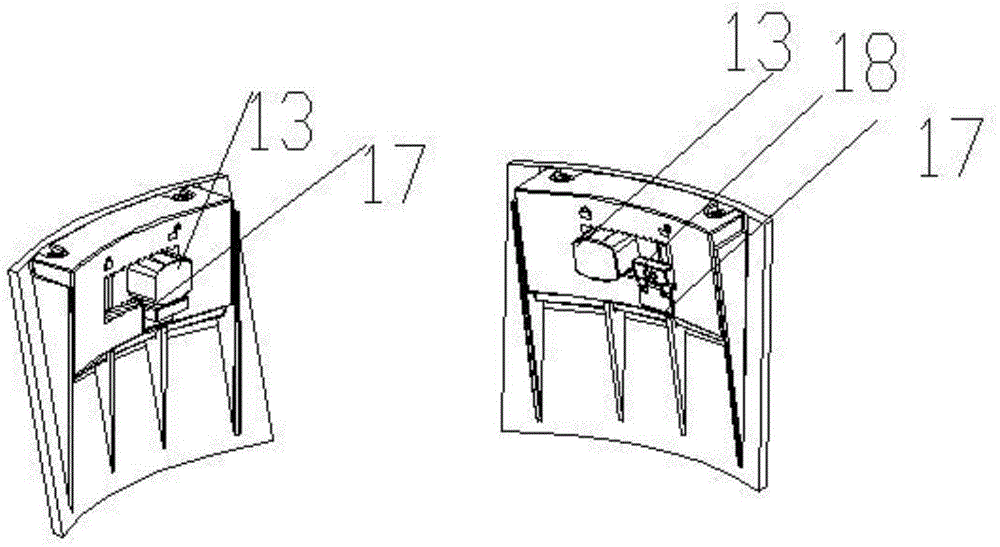

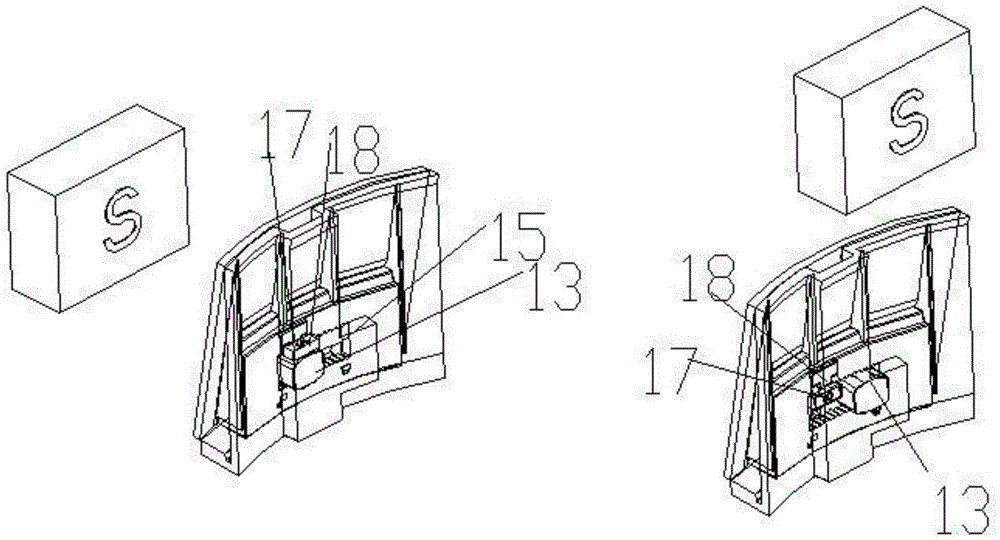

[0028] refer to figure 1 , 2 As shown, a housing connection structure provided by the present invention includes a first housing 10, a second housing 20 and a locking assembly, the first housing 10 is connected to the second housing 20, and the housing locks The lock assembly is installed in the first housing 10 and the second housing 20, the lock housing assembly includes a locking magnet 12, a lock 13, a lock cover 14, a hinge assembly 17 and a hinge magnet 18;

[0029] Locking magnet 12, the locking magnet 12 is fixedly installed on the lock cover 14, used to guide the lock to lock in place;

[0030] Lock 13, the lock 13 is installed on an outer surface of the chute 15 of the lock cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com