Improved control grip

A technology for controlling handles and areas, used in bicycle control systems, bicycle accessories, transportation and packaging, etc., can solve problems such as failure, cable breakage, discomfort, etc., to reduce wear and cost, improve reliability, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

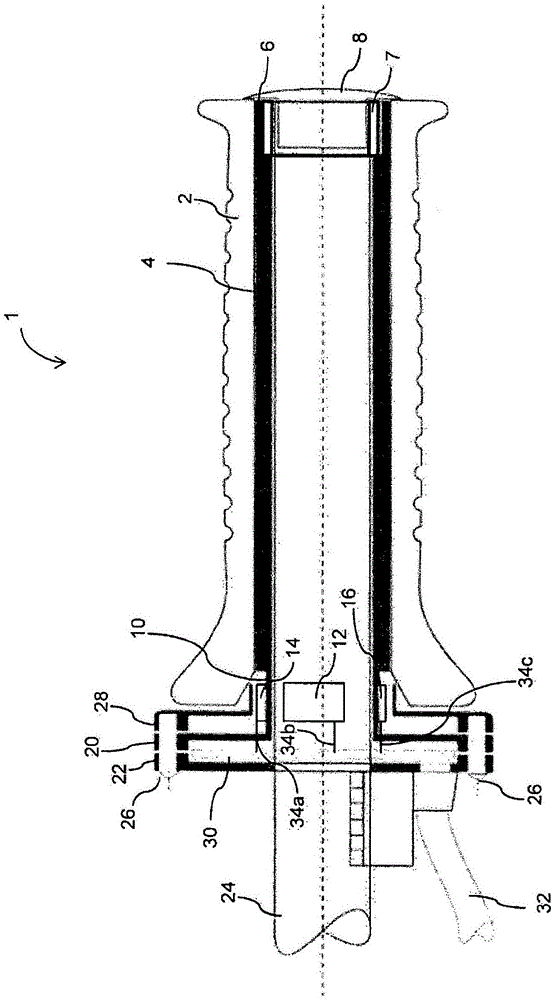

[0028] refer to figure 1 , figure 1 A sectional view showing the guide bar and the control handle 1 of the vehicle. The control handle 1 includes a hand glue 2 and a grip tube 4 . The hand glue 2 and the grip tube 4 constitute a grip area. Drivers of vehicles such as motorcycles, tricycles, quads, snowmobiles, jet skis, etc. are used to hold the hand gel 2 . The hand glue 2 is rigidly connected with the grip tube 4 . To control the speed, the driver applies torque to the grip tube 4 via the grip area 2 .

[0029] The grip tube 4 is connected rigidly and non-rotatably to a link 24 of the vehicle via the detection region 10 and the control handle-side mounting region 20 and the link-side mounting region 22 . The torque exerted by the driver causes a twist in the gripping tube 4 , in the detection region 10 , in the installation regions 20 , 22 and in the link 24 , since the gripping regions 2 , 4 are rigidly connected to the link 24 . Since the detection region 10 is confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com