Rail fastening point and base plate for such a rail fastening point

A technology for fixing points and tracks, applied in the direction of fixing rails, tracks, roads, etc., can solve the problem of expensive manufacturing technology, and achieve the effect of easy installation, light weight and less material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

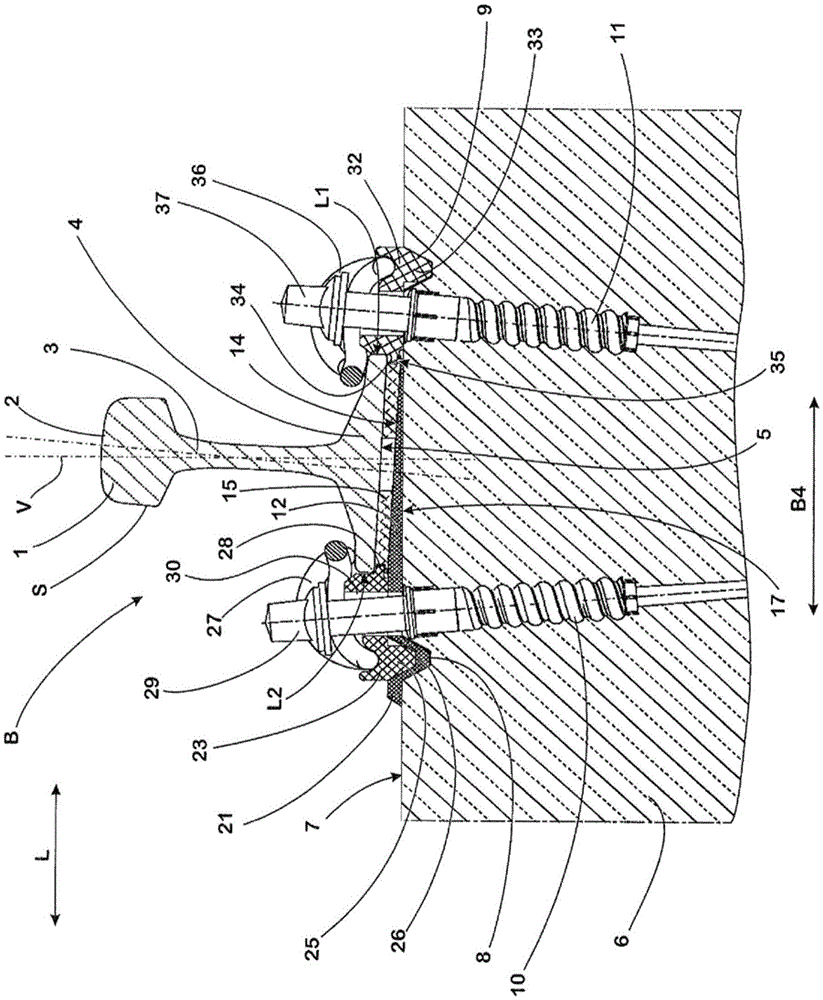

[0041] Track S is fixed on the attached figure 1 On the rail fixing point B shown in , it generally has: a rail head 1, on the upper side of which is formed a running surface 2 for rail wheels (also not shown) of a rail vehicle (not shown); A rail web 3 supporting the rail head 1; and a rail base 4, which is arranged at the center of the rail base. The rail base 4 is wider than the rail head 1 and has a flat support surface 5 on its underside.

[0042] The track fixing point B comprises a foundation 6 which in the present embodiment is formed by a conventional type of sleeper cast in concrete. On its upper side, the foundation 6 has a flat contact surface 7 which extends over the length of the foundation 6 measured in a foundation longitudinal direction L aligned transversely to the rail S. As shown in FIG.

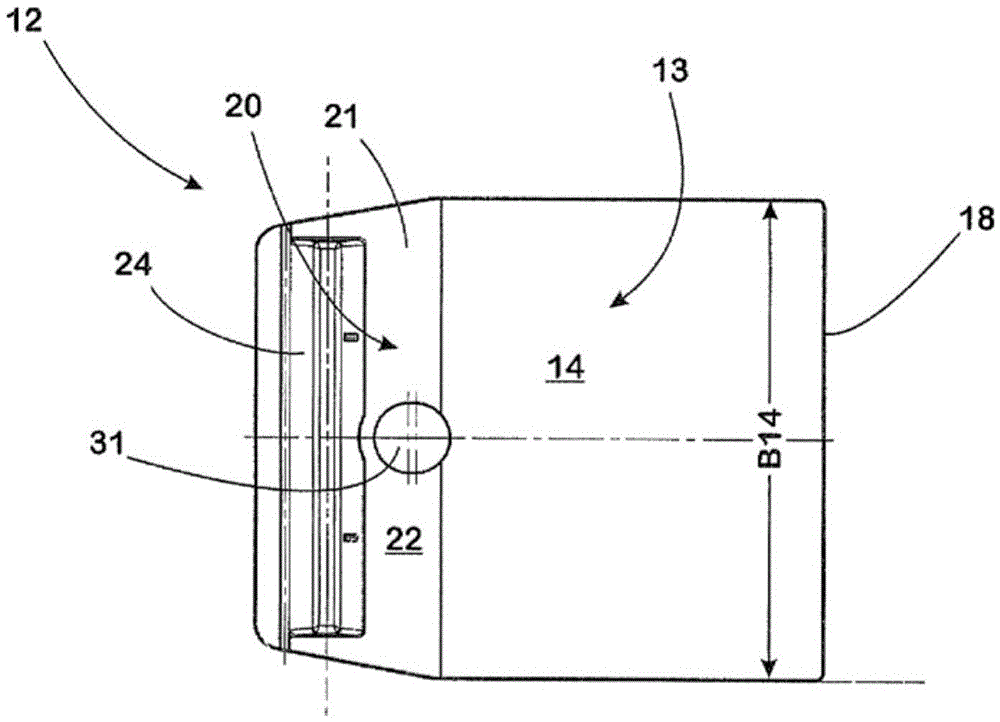

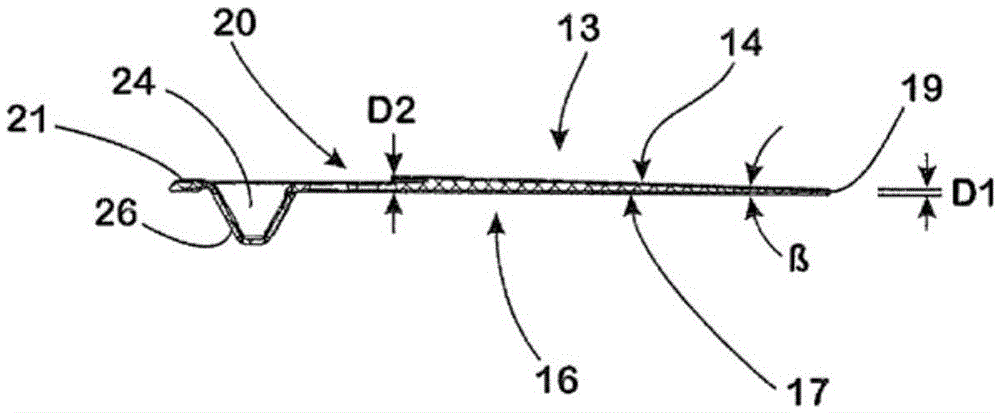

[0043] Two groove-like recesses 8 , 9 are formed at a distance from one another on the contact surface 7 , which extend parallel to each other and to the longitudinal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com