Printed wiring board and connector connecting said wiring board

A printed wiring board and wiring technology, applied in the direction of connection, printed circuit, printed circuit, etc., can solve the problems of not being able to obtain sufficient strength and difficulty in ensuring the retention of the wiring board, achieve excellent pull-out resistance, and eliminate ground short circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

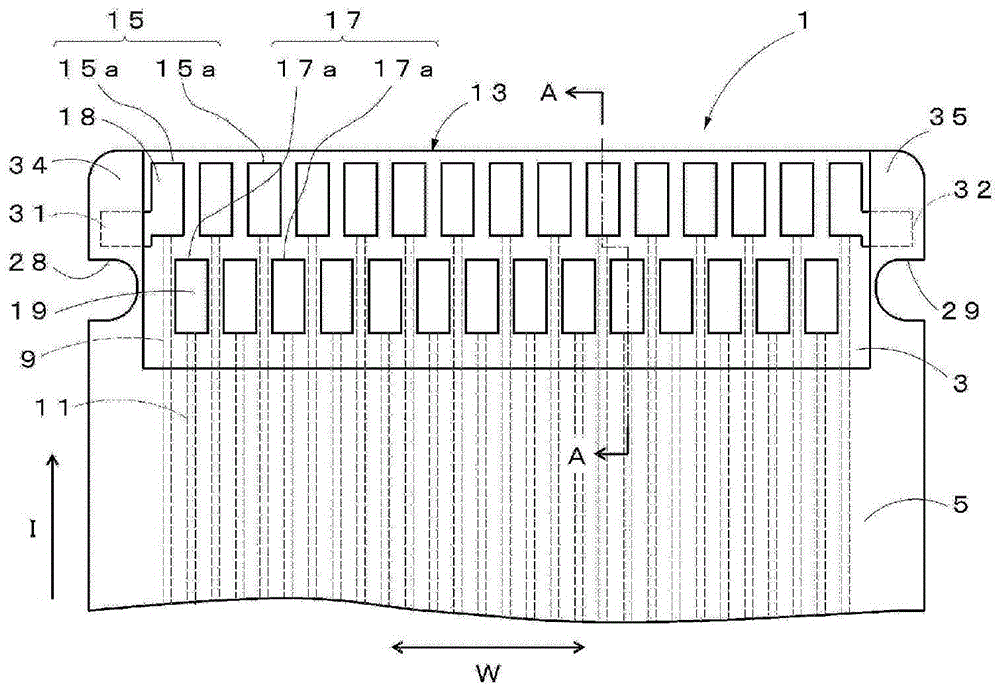

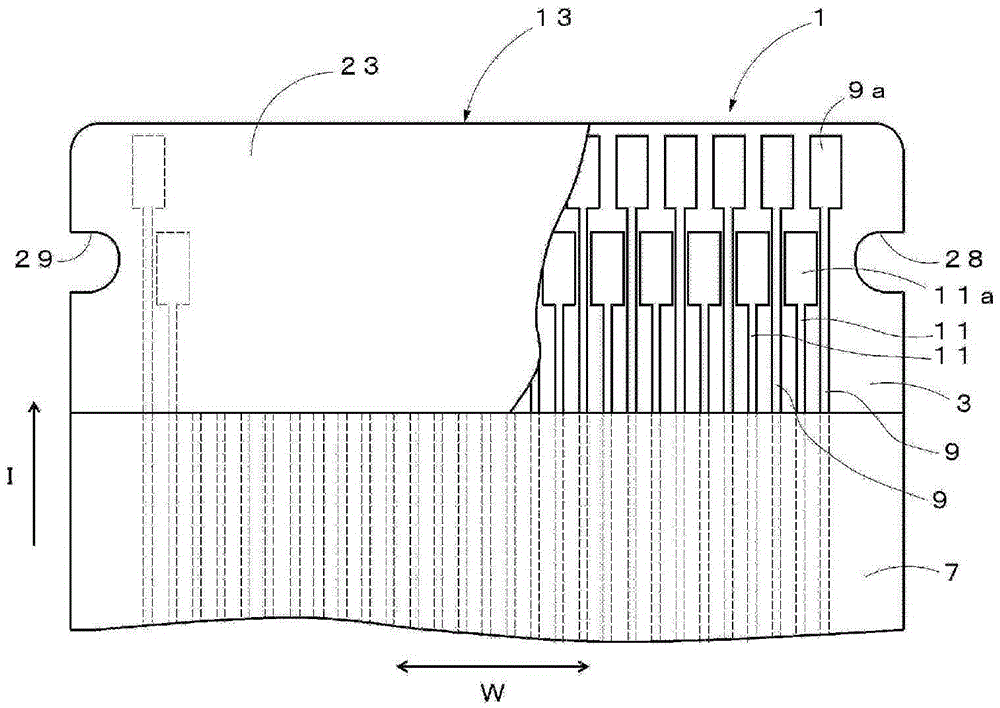

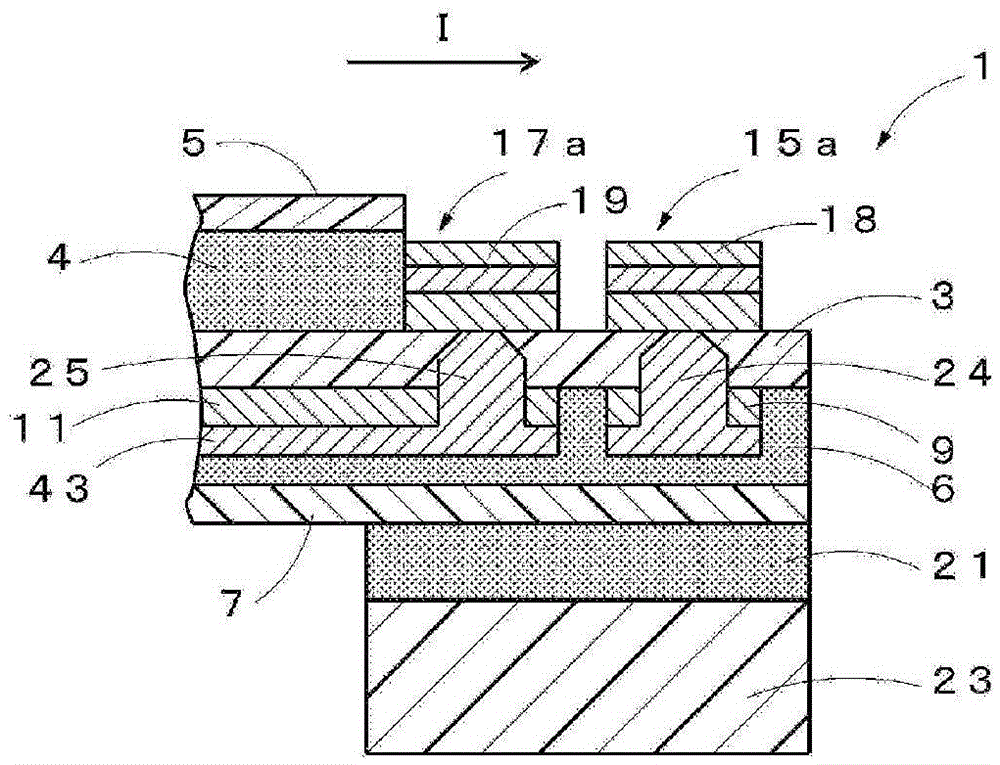

[0098] As Example 1, a trial production with Figure 1~4 The flexible printed wiring board of the structure shown. Specifically, the flexible printed wiring board has fifteen spacers in the front row and fourteen spacers in the back row at the connection end, and the space between the spacers is 0.175mm (0.35mm between each column). The surface (back surface) of the film on the opposite side to the surface on which the spacers are provided has the wiring of the spacers in the front row and the wiring of the spacers in the rear row, and is arranged on the front side and the front side of the notch (part to be engaged). Reinforcement layer integral with spacer. In addition, an insulating layer is formed on the upper surface of the reinforcement layer by the extending portion of the upper surface side covering layer. Spacers, wiring, and reinforcing layers are made of copper, and a gold-plated layer is formed on top of the spacers. As the base film, a film made of polyimide wi...

Embodiment 2

[0100] As Example 2, only as Figure 13 The shown flexible printed wiring board is different from Example 1 in that a reinforcement layer is formed independently on the upper surface side (the side where the spacer is formed) of the base film and does not have an insulating layer covering the reinforcement layer.

Embodiment 3

[0102] As Example 3, a trial production such as Figure 14 As shown, the flexible printed wiring board differs from Example 2 only in that it has the insulating layer which covers a reinforcing layer. Specifically, in the flexible printed wiring board of Example 3, the insulating layer covering the reinforcing layer is formed by the extended protrusion extending forward from the widthwise outer portion of the upper cover layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com