Down jacket with double-layer down locking structure

A down jacket and down-locking technology, applied in the field of down jackets, can solve the problems such as damage to the down jacket fabric, reduced down content in the inner liner, easy occurrence of scratches, etc., and achieves the effects of good ductility, increased warmth retention, and convenience and integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

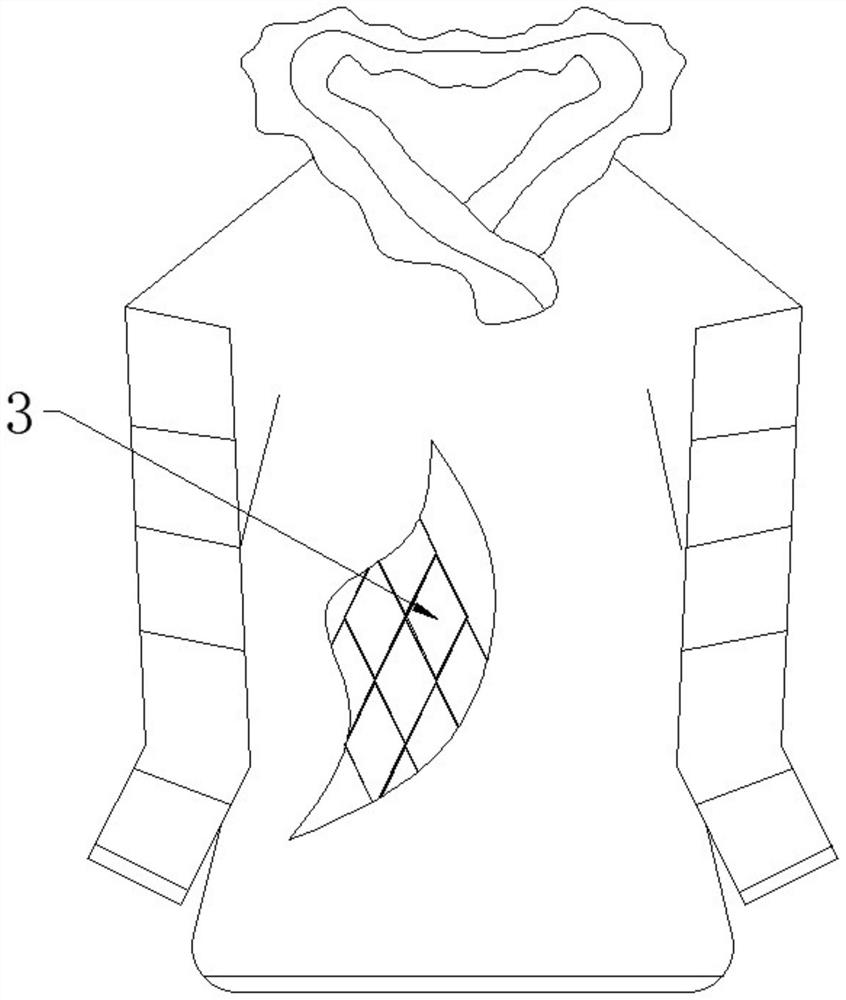

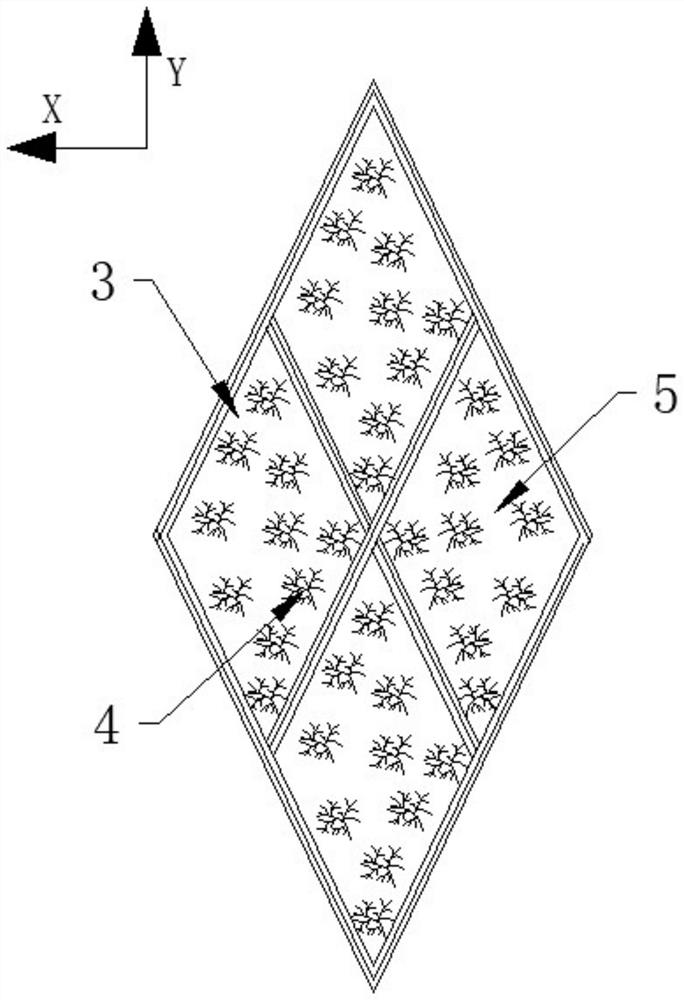

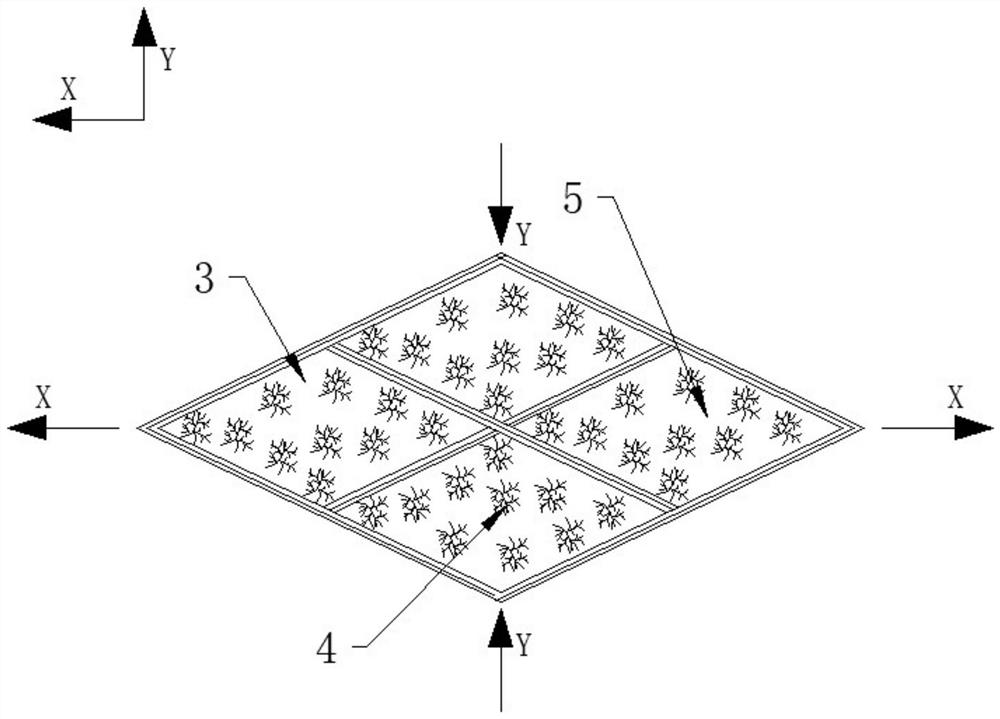

[0053] like Figure 1-2 As shown, a kind of down jacket with double-layer lock down structure includes inner layer fabric 1 and outer layer fabric 2, and between inner layer fabric 1 and outer layer fabric 2, a diamond-shaped inner liner 3 is formed by hot pressing, and the diamond-shaped inner liner 3 is on the Four sets of diamond-shaped cavities 5 are formed through cross-stitching, and the first down 4 is arranged in the four sets of diamond-shaped cavities 5;

[0054] like Figure 2-4 As shown in the figure, the deformability of the rhombus is good, and the rhombus 3 is formed by hot pressing. image 3 When pulling in the X direction, it is easy to make the diamond-shaped inner container 3 extend along its diagonal direction. At this time, the X-direction can be extended, and at the same time, the Y-direction is compressed, which facilitates the overall deformation of the diamond-shaped inner container 3, and has good pulling resistance. It can effectively prevent exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com