Complex catalyst containing diphosphine ligand

A technology of bisphosphine ligands and catalysts, which is applied in the field of complex catalysts, can solve the problems of large amount of ligands, low positive/isotropic ratio of product butyraldehyde, easy ligand decomposition, etc., and achieve good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

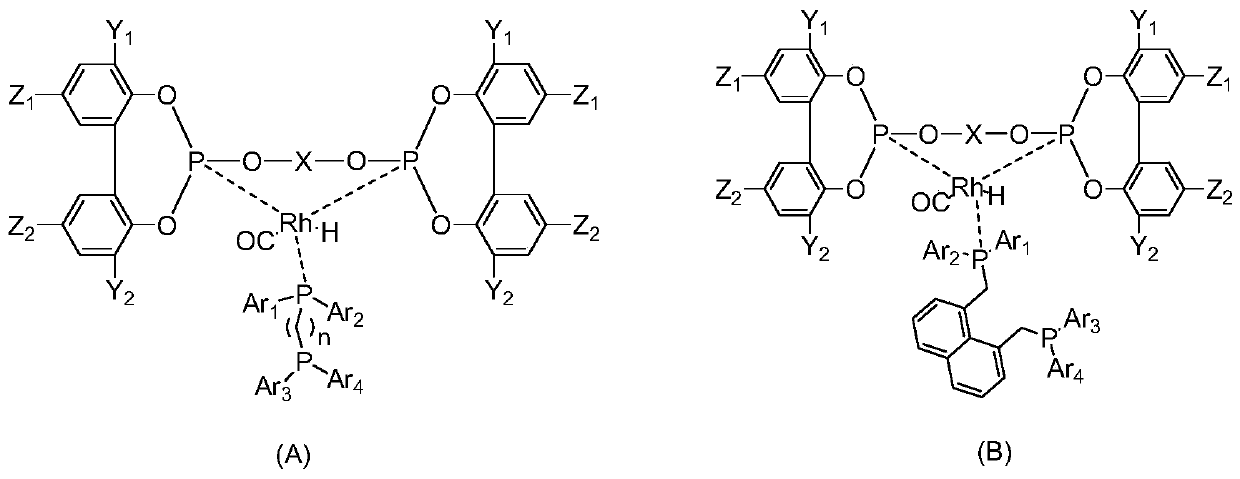

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

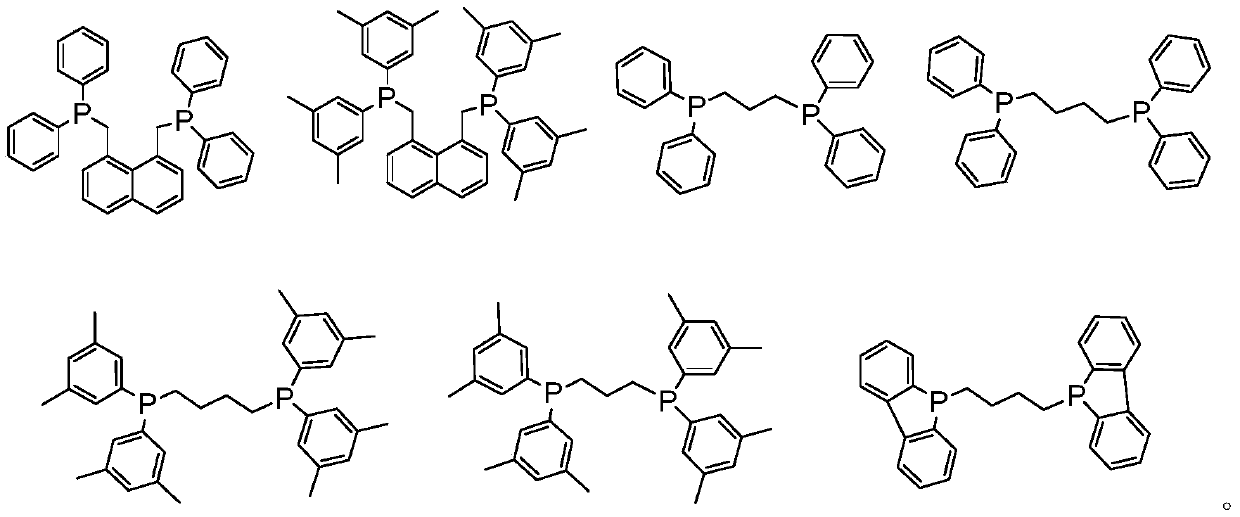

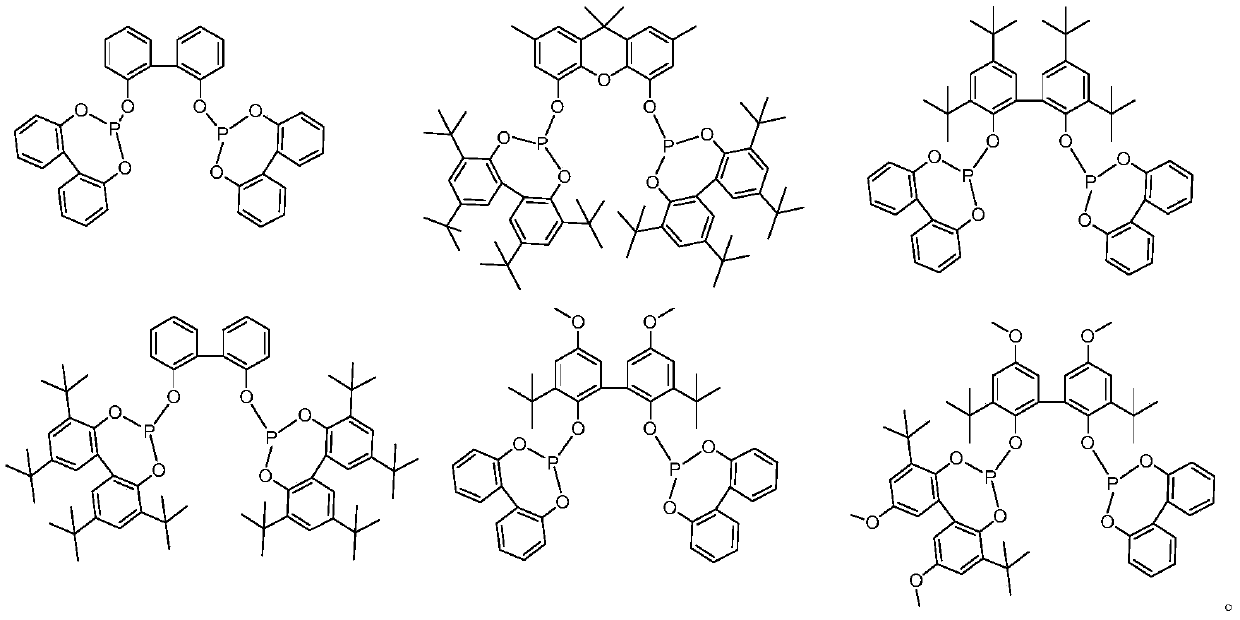

[0029] Add [Rh(acac)(CO) to a 200mL stainless steel autoclave equipped with a pressure gauge under air atmosphere 2 ] (0.07mmol, 18.1mg) and 0.14mmol of 1,3-bis(diphenylphosphine)propane L3 bidentate phosphine ligand and 0.14mmol of L12 bidentate phosphite ligand, and 70mL of anhydrous toluene, connected Gas pipeline, after replacing the gas in the kettle with synthesis gas (hydrogen: carbon monoxide = 1:1) three times, stir with an electromagnetically driven mechanical stirrer, heat up to the temperature inside the kettle at 100°C, and feed synthesis gas until the total pressure is 2.0MPa , reacted at 100°C and 2.0MPa for 1h to prepare rhodium / (bidentate phosphite-bisphosphine ligand) complex catalyst HRh(L12)(L3)(CO). Its molecular structure is as follows: 31 PNMR (Toluene, 162MHz) P1 of L12 coordinated with rhodium: δ180.7ppm, P2 of L12 coordinated with rhodium: δ176.0ppm, P3 of L3 coordinated with rhodium: 24.0ppm, P4 of L3 in the complex: -19.6ppm, 1 J RhP1 = 248Hz,...

Embodiment 2

[0032] Add [Rh(acac)(CO) to a 200mL stainless steel autoclave equipped with a pressure gauge under air atmosphere 2 ] (0.07mmol, 18.1mg) and 0.14mmol of the BISBI ligand L1 bidentate phosphine ligand and 0.14mmol of the L12 bidentate phosphite ligand, and 70mL of anhydrous toluene, connect the gas line to the synthesis gas (hydrogen: Carbon monoxide = 1:1) After replacing the gas in the kettle three times, stir with an electromagnetically driven mechanical stirrer, heat up to the inner temperature of the kettle at 100°C, and feed synthesis gas until the total pressure is 2.0MPa, at 100°C, 2.0MPa After reacting for 1 h, the rhodium / (bidentate phosphite-bisphosphine ligand) complex catalyst HRh(L12)(L1)(CO) was obtained. Its molecular structure is as follows: 31 PNMR (Toluene, 162MHz) P1 of L12 coordinated with rhodium: δ179.8ppm, P2 of L12 coordinated with rhodium: δ175.9ppm, P3 of L1 coordinated with rhodium: 30.1ppm, P4 of L1 in the complex: -11.2ppm, 1 J RhP1 = 249Hz, 1...

Embodiment 3

[0035] Add [Rh(acac)(CO) to a 200mL stainless steel autoclave equipped with a pressure gauge under air atmosphere 2 ] (0.07mmol, 18.1mg) and 0.14mmol of 1,4-bis(diphenylphosphine)butane L4 bidentate phosphine ligand and 0.14mmol of L10 bidentate phosphite ligand, and 70mL of anhydrous toluene, Connect the gas pipeline, replace the gas in the kettle with synthesis gas (hydrogen: carbon monoxide = 1:1) three times, stir with an electromagnetically driven mechanical stirrer, heat up to 100°C inside the kettle, and feed synthesis gas until the total pressure is 2.0 MPa, under the conditions of 100° C. and 2.0 MPa, react for 1 h to prepare rhodium / (bidentate phosphite-bisphosphine ligand) complex catalyst HRh(L10)(L4)(CO). Its molecular structure is as follows: 31 PNMR (Toluene, 162MHz) P1 of L10 coordinated with rhodium: δ179.8ppm, P2 of L10 coordinated with rhodium: δ176.2ppm, P3 of L4 coordinated with rhodium: 24.4ppm, P4 of L4 in the complex: -15.6ppm, 1 J RhP1 = 249Hz, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com