Explosive welding support device and application thereof

A support device and explosive welding technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems that the support body is not easy to pull out, the support body should not be too long, and the position of the double board can move, etc., to achieve Improve hoisting efficiency and improve the effect of easy and difficult to put

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

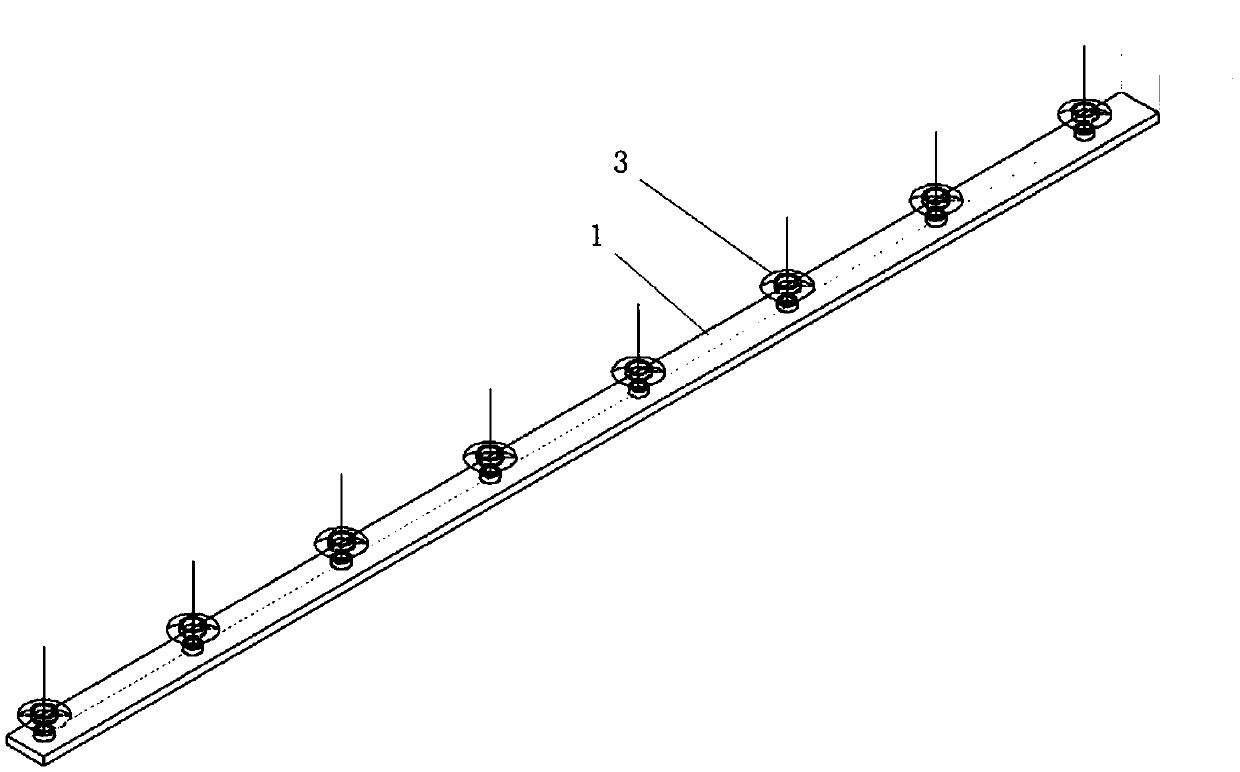

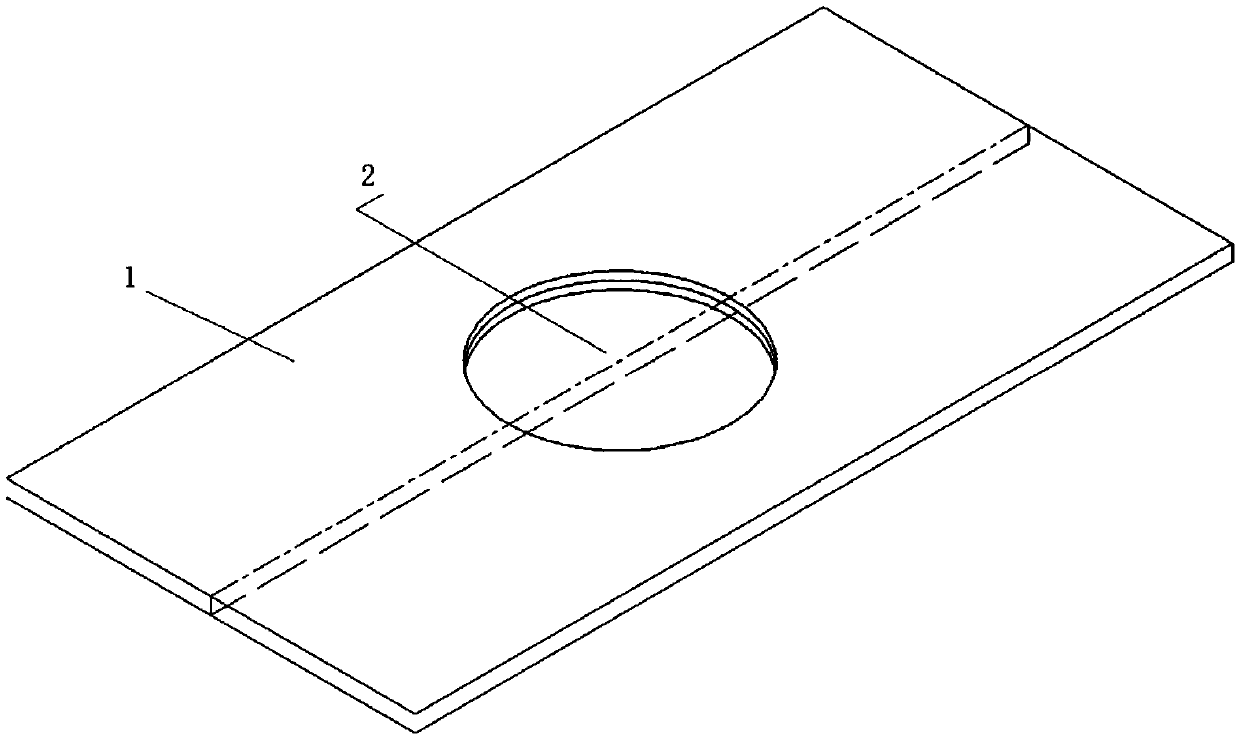

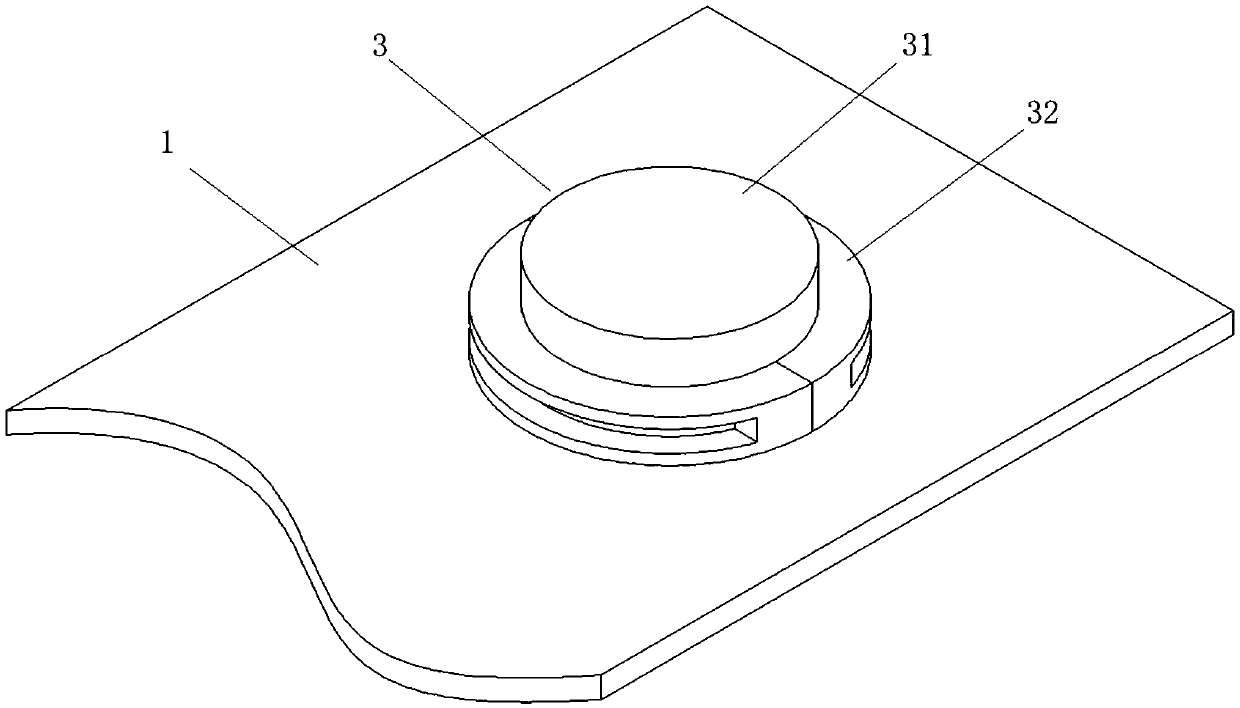

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, an explosive welding support device has a strip-shaped base 1 with a thickness of about 2mm and an overall length of about 1.5m. . A plurality of threaded holes 2 are arranged side by side on the base 1, and a support member 3 is threadedly connected to the threaded holes 2. The support member 3 includes a lower support member 32 and an upper support member 31; the lower support member 32 is a ring structure, and the inside is a hole , the lower supporting part 3 includes a circular ring structure 321 and a limiting ring 322 arranged on the upper end of the circular ring structure 321 , the inner diameter of the limiting ring 322 is smaller than the inner diameter of the circular ring structure 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com