Mandrel for injection blow molding mold

A forming mold and injection blow molding technology, which is applied in the mandrel field of injection blow molding moulds, can solve the problems of twisting of the bottle mouth, reducing the appearance of the bottle mouth, and poor shaping effect, etc., to achieve beautiful appearance and uniform thickness of the bottom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

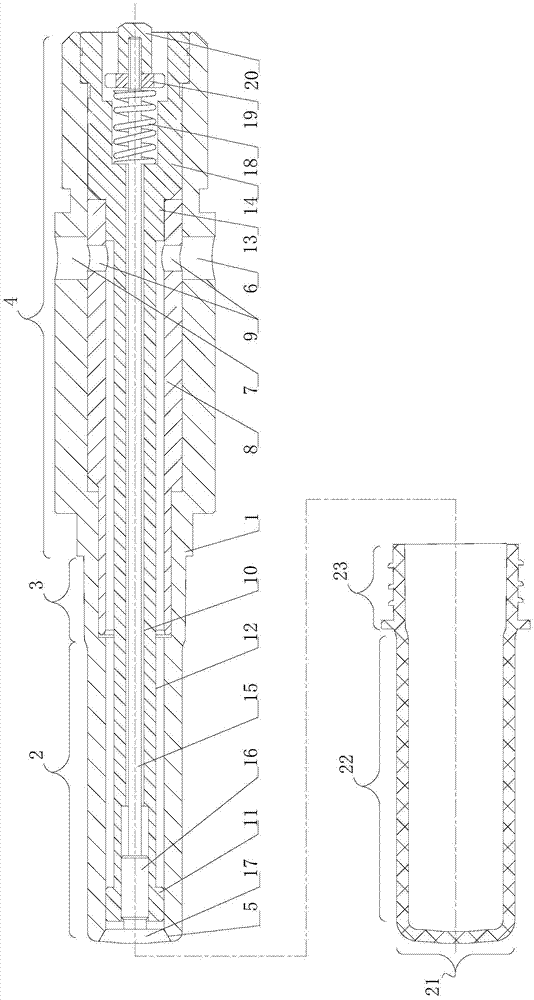

[0022] The first embodiment of the present invention, such as figure 1 shown.

[0023] The mandrel of the injection blow molding mold is provided with a shell 1, a ventilation pipe 10, a heat insulating pipe 8, and an air intake part.

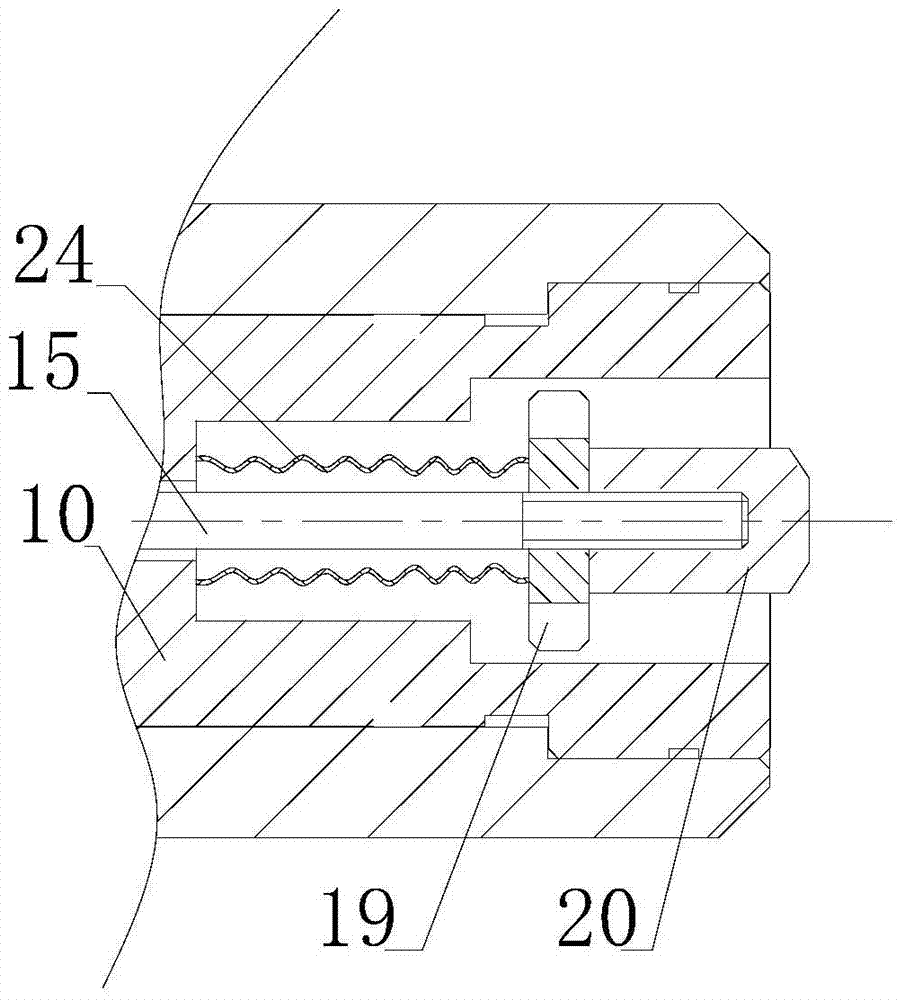

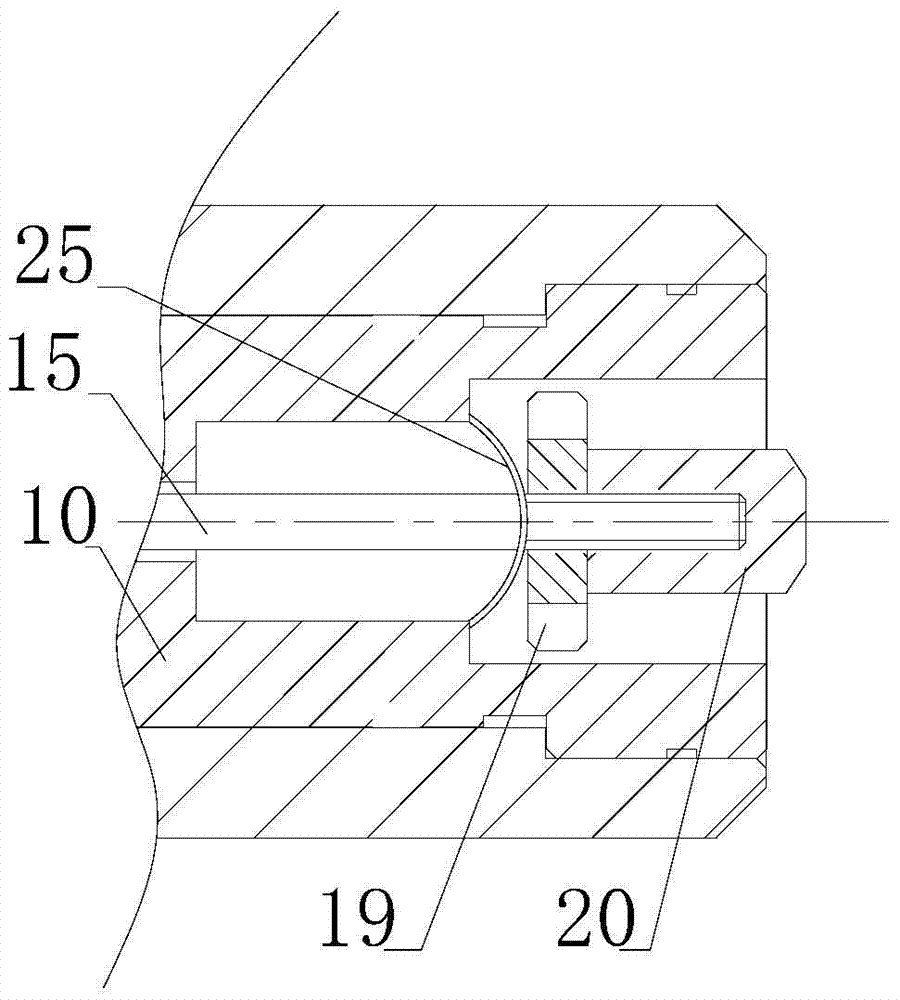

[0024] The casing 1 is made of metal and has a tubular structure as a whole. The casing 1 is divided into three parts, namely the inflation part 2 , the preform restriction part 3 and the installation part 4 . The functions of the three parts are different, among which the inflation part 2 is in contact with the middle part of the preform and the end of the preform, and is used as a mold when making a preform, and guides the inflation process during blowing. The outer surface of the casing 1 at the inflated part 2 is provided with a smooth and rounded structure, such that the outer surface of the structure corresponds to the inner structure of the preform. Three parts are distributed sequentially on the housing 1, the preform restricting part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com