Paper structure used for secondary printing of printer

A secondary printing and printer technology, applied in the direction of printing, copying/marking methods, etc., can solve the problem of poor pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

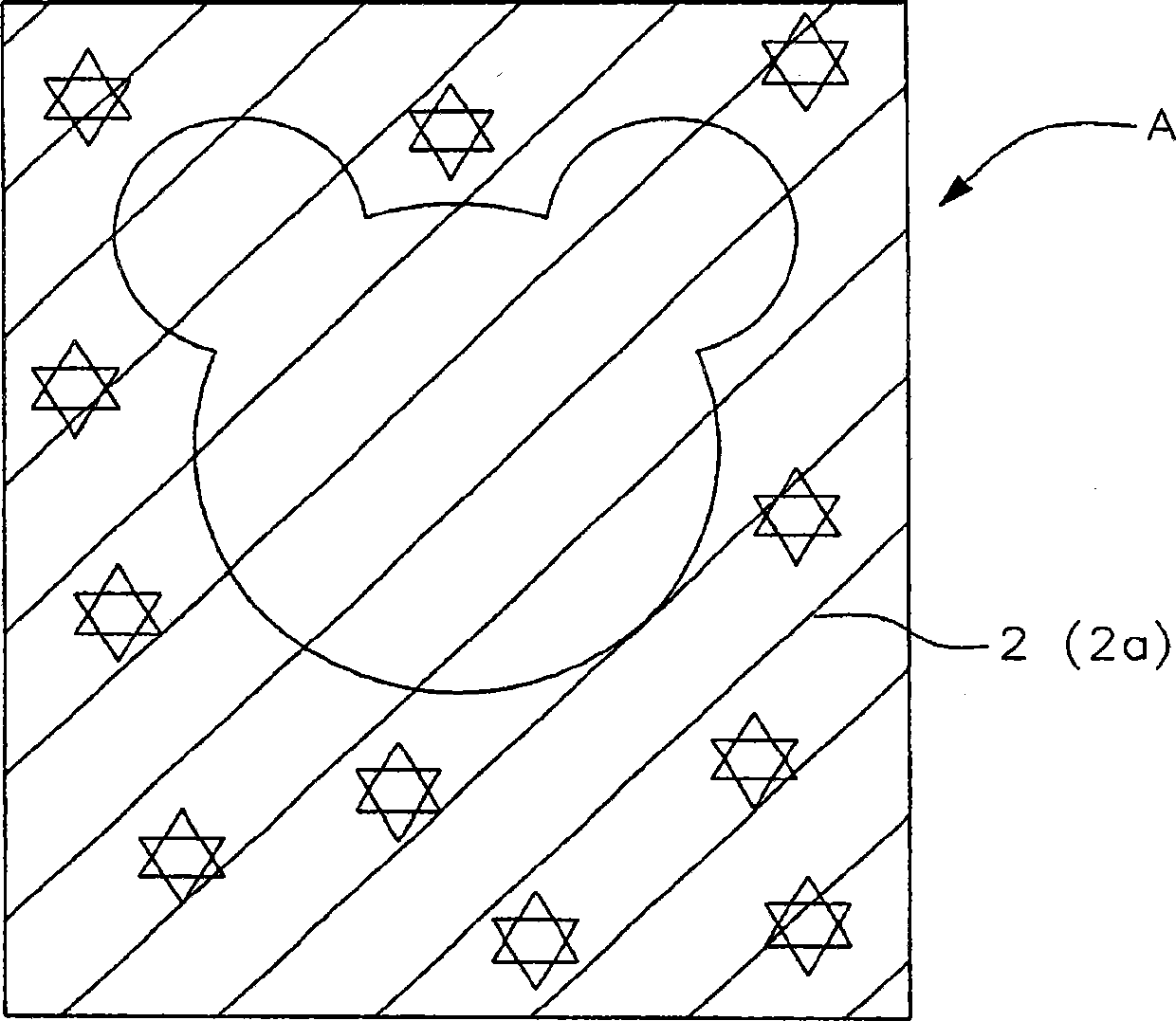

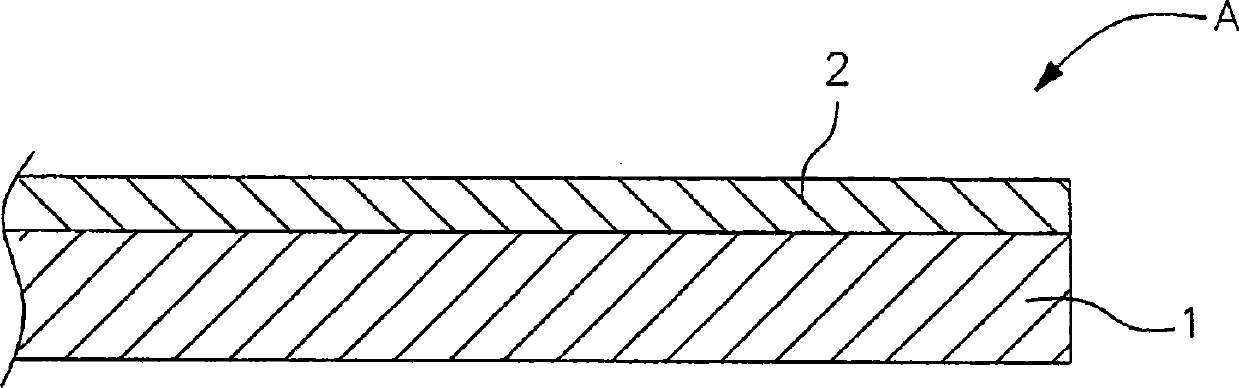

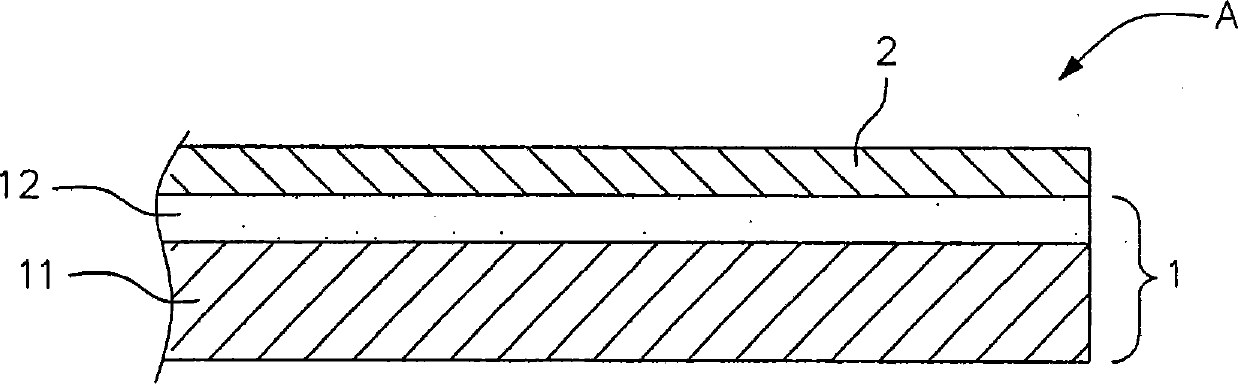

[0012] Structure, feature and effect thereof of the present invention, further elaborate as follows according to the embodiment of accompanying drawing:

[0013] figure 1 It is a schematic plan view of the paper structure used by the printer for secondary printing of the present invention, figure 2 for figure 1 A schematic cross-sectional view of the paper structure shown, image 3 for figure 1 A schematic cross-sectional view of another embodiment of the paper structure shown. Such as figure 2 As shown, the paper structure A for the secondary printing of the printer in the present invention includes: a paper body 1; and a water-soluble ink surface layer 2 that has been pre-printed into a part of the design pattern.

[0014] The above paper body 1 can be general paper or photographic paper. Such as image 3 As shown, the photographic paper material (ie, the paper material body 1 ) is the same as general photographic paper, including a photographic paper substrate 11 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap