Frame assembly line trolley with adjustable width dimension

A technology of opening size and assembly line, which is applied in the direction of motor vehicles, transportation and packaging, etc. It can solve the problems of heavy weight of a single longitudinal beam and laborious longitudinal beams, and achieve the effects of low manufacturing cost, convenient installation of longitudinal beams, and convenient fine-tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

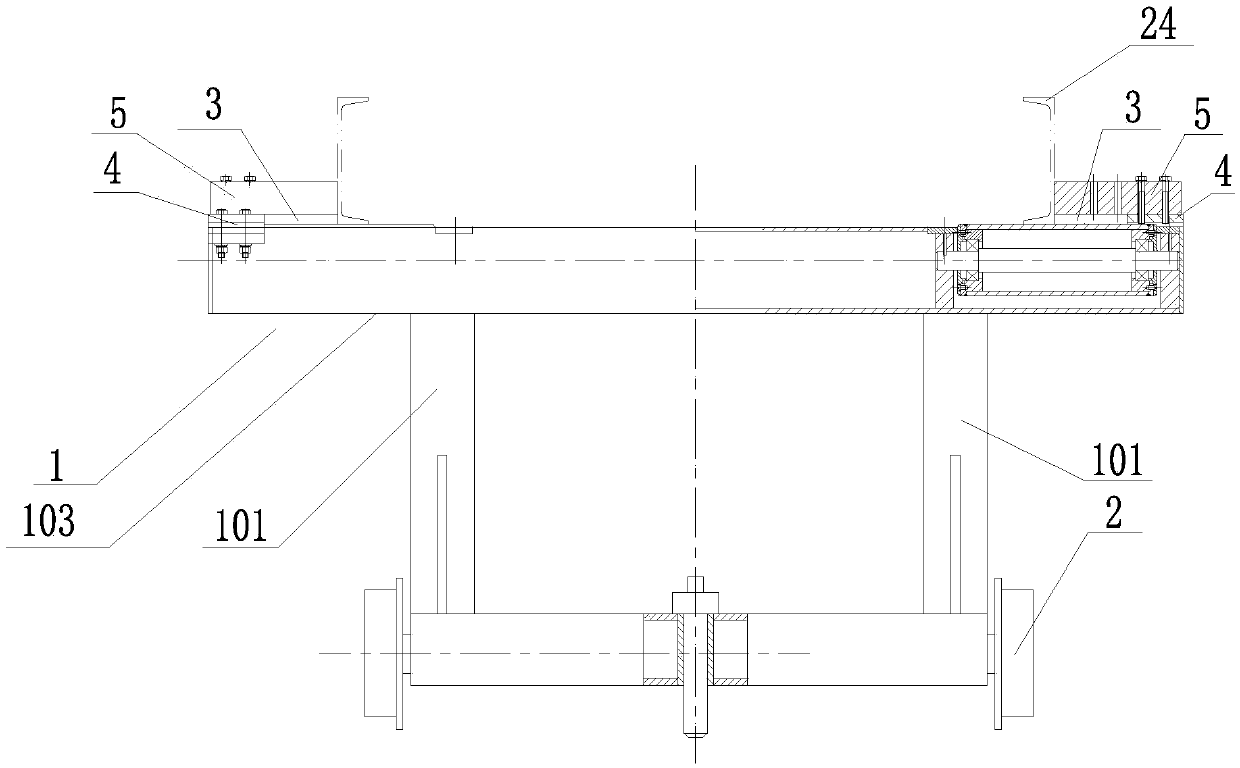

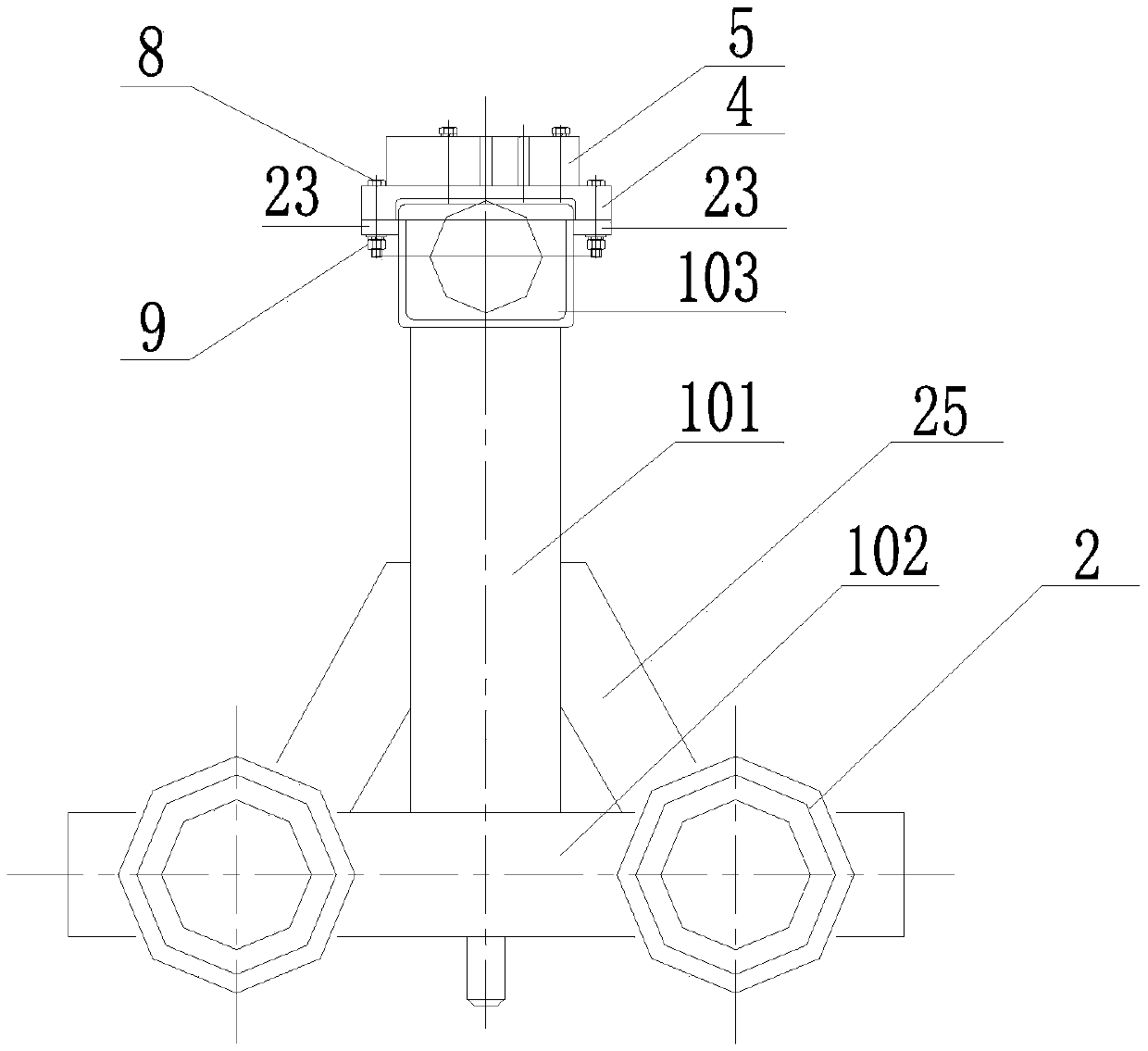

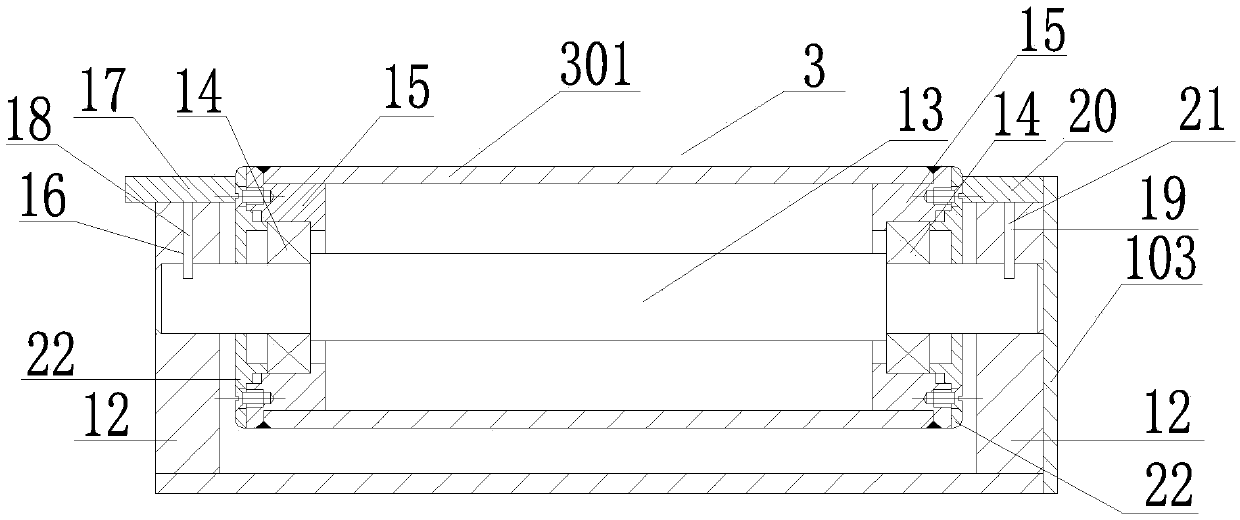

[0025] like figure 1 The frame assembly line trolley with adjustable opening size shown in —6 includes a trolley support 1, the bottom of the trolley support 1 is provided with wheels 2; The two ends of the top of the bracket 1 are fixed with a fixed plate 4, and the fixed plate 4 is fixed with an adjustment block 5, and the fixed plate 4 and the adjustment block 5 are respectively provided with multiple sets of fastening structures that cooperate with each other. The roller table 3 adjusts the front and rear positions of the vehicle frame longitudinal beam 24, and the fixed plate 4 and the adjustment stopper 5 cooperate with each other to adjust the distance between the adjustment stoppers 5 so that it corresponds to the length of the vehicle frame longitudinal beam 24, which can satisfy multiple requirements. Transportation require...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap