Linkage production method and linkage production line of color-printing corrugated case

A production method and technology of color printing tiles, applied in the direction of papermaking, paper/cardboard containers, containers, etc., can solve the problems of high labor intensity, low degree of automation, and dirt, so as to improve the drying effect and realize the effect of automatic feeding and turning Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

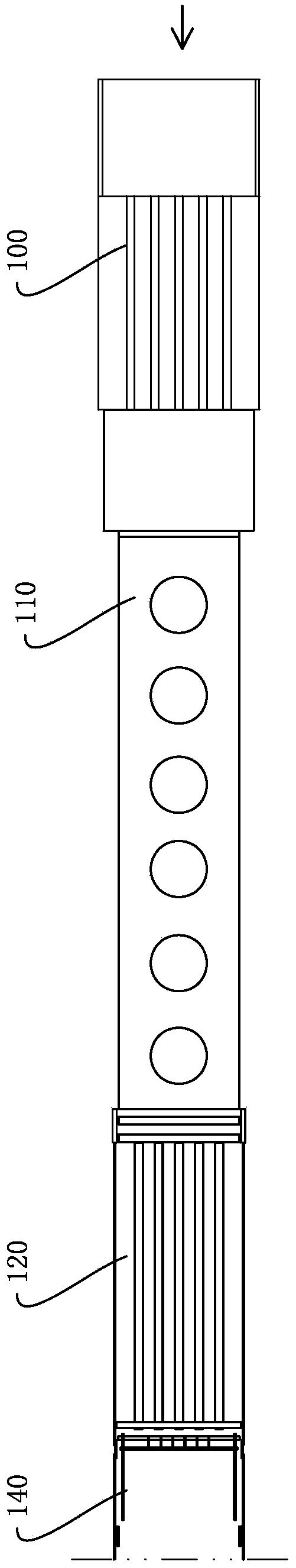

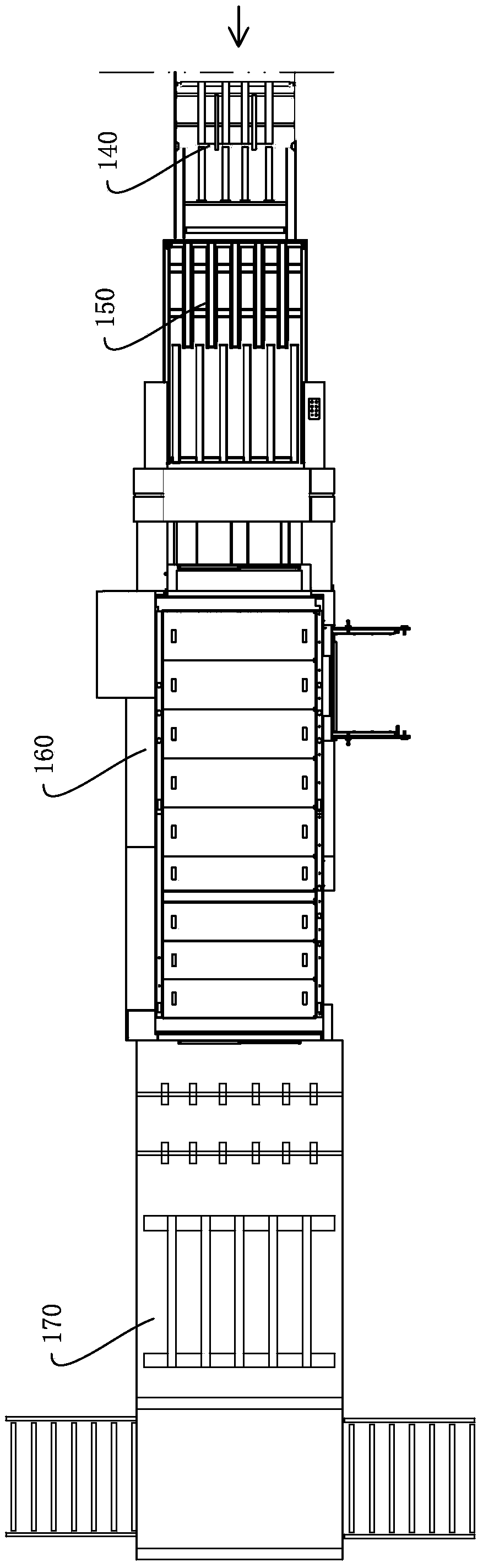

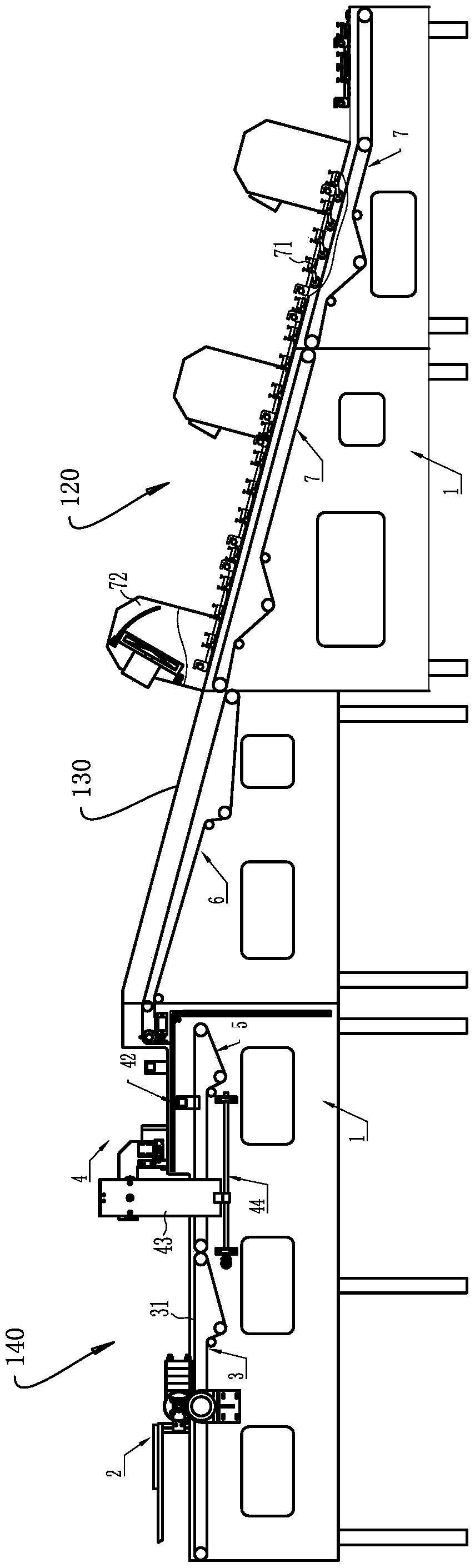

[0035] The production line is very long. For the sake of clarity, it is divided into two parts along the direction of the arrow. The upstream part is indicated in figure 1 , the downstream part is represented in figure 2 middle. The direction of travel of the cardboard is defined as front-to-back and derived left and right.

[0036] Such as figure 1 with figure 2 Commonly shown, a corrugated box linkage production line, it is intelligent, the central electronic control system controls the communication and speed synchronization of each stand-alone equipment, such as PLC or industrial computer, etc., to ensure the continuity of production.

[0037] The paper laminating machine 100 is used for laminating the top paper and the bottom paper into corrugated cardboard. Color pictures and texts are printed on the top paper in advance. Before the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com