VOC emission-free environment-friendly UV gloss oil for laminated steel and preparation method thereof

A varnish, environmentally friendly technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problem of not being able to meet the adhesion, hardness, toughness and other problems at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The second aspect of the present invention provides a method for preparing the above-mentioned non-VOC emission environment-friendly UV varnish, comprising the following steps:

[0057] (1) Mixing modified epoxy acrylic resin, aminoacrylic resin and diluted monomer to obtain a premix;

[0058] (2) Add the photoinitiator into the premix and mix to obtain the varnish.

[0059] In one embodiment, the preparation method of the VOC emission-free environment-friendly UV varnish of the present invention comprises the following steps:

[0060] (1) After mixing the modified epoxy acrylic resin, aminoacrylic resin, and diluting monomer at 400-500r / min for 5-10min, mix at 1000-1500r / min for 10-20min to obtain a premix;

[0061] (2) Add photoinitiator and auxiliary agent into the premix, mix at 400-500r / min for 5-10min, then mix at 1000-1500r / min for 20-50min to obtain the varnish.

[0062] In one embodiment, the application of the non-VOC emission-friendly UV varnish of the pres...

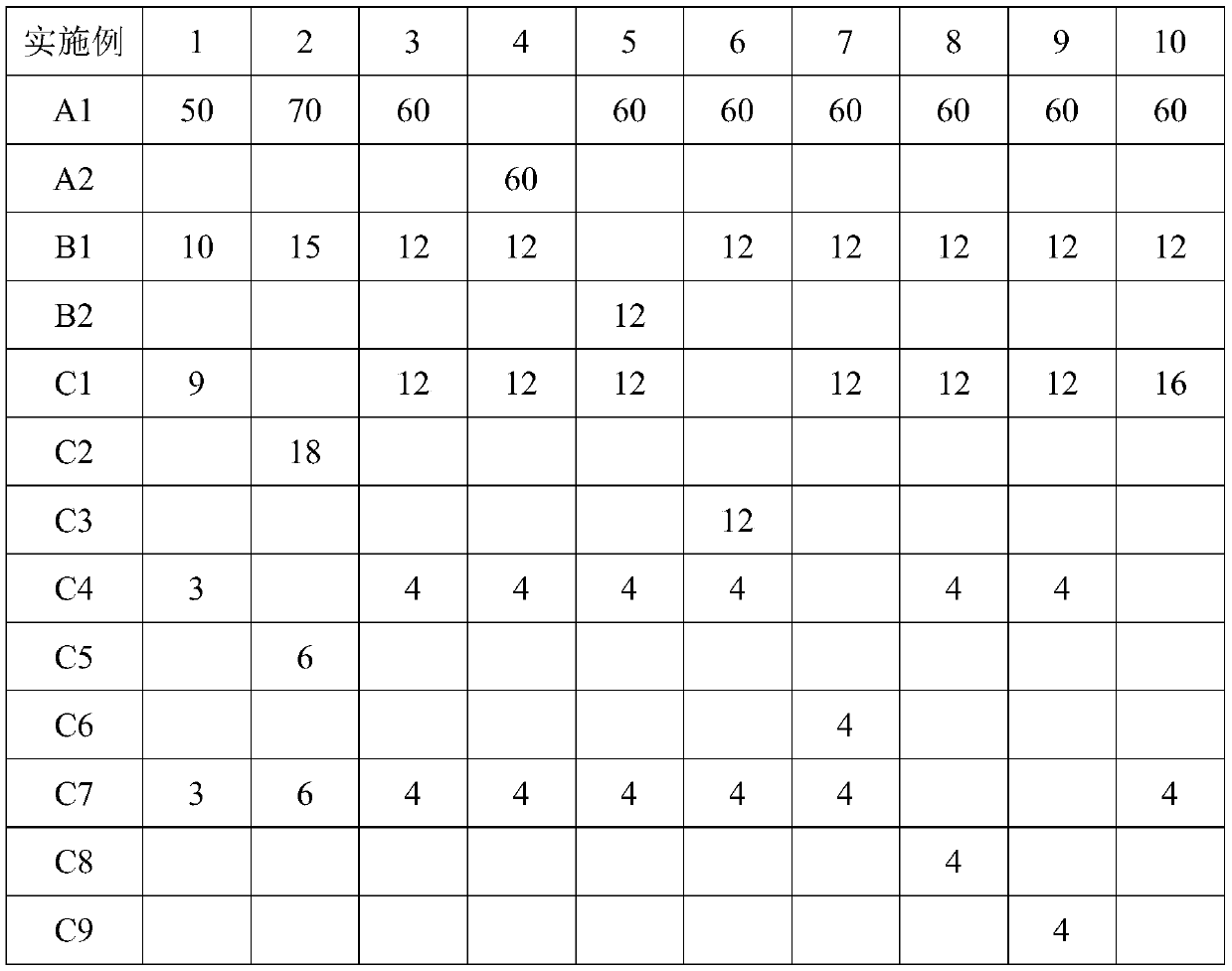

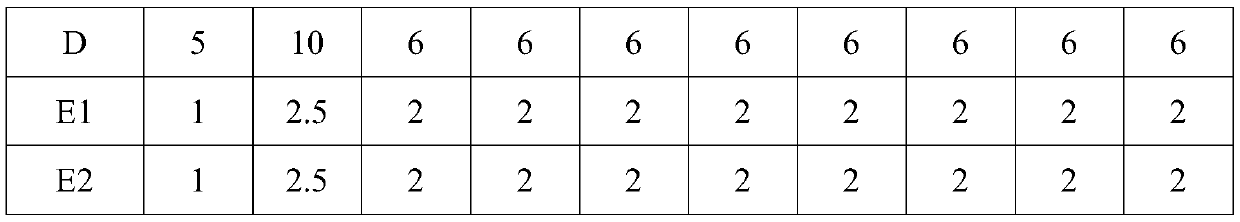

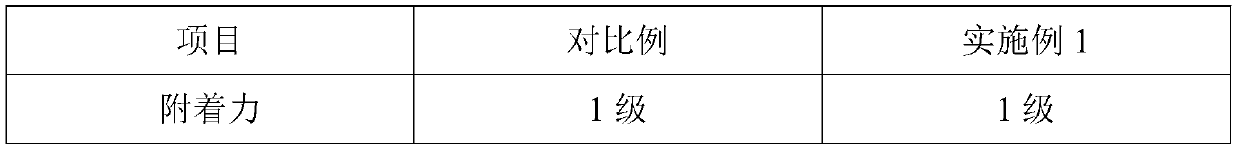

Embodiment

[0068]The present invention is specifically described below by way of examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the content of the present invention above And adjustments still belong to the protection scope of the present invention.

[0069] A1: Modified epoxy acrylic resin

[0070] The modified epoxy acrylic resin is a fatty acid modified epoxy acrylic resin, purchased from Guangzhou Handong New Material Technology Co., Ltd. H3165.

[0071] A2: Modified epoxy acrylic resin

[0072] The modified epoxy acrylic resin is a fatty acid modified epoxy acrylic resin, purchased from Guangzhou Handong New Material Technology Co., Ltd. B5293.

[0073] B1: aminoacrylic resin

[0074] The aminoacrylic resin was purchased from Jiangsu Sanmu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com