A material transfer device

A technology for transferring devices and materials, which is applied to conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of inability to send steel pipes into the straightening machine for straightening, dangers caused by traveling and hoisting, and safety of steel pipes. The effect of improving space utilization, avoiding cranes, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

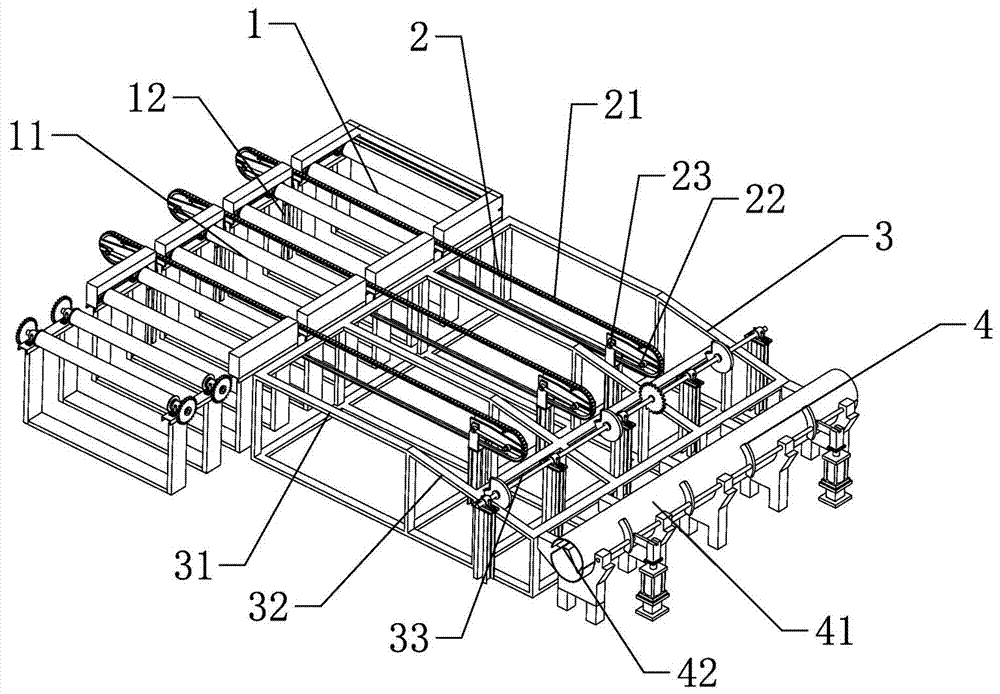

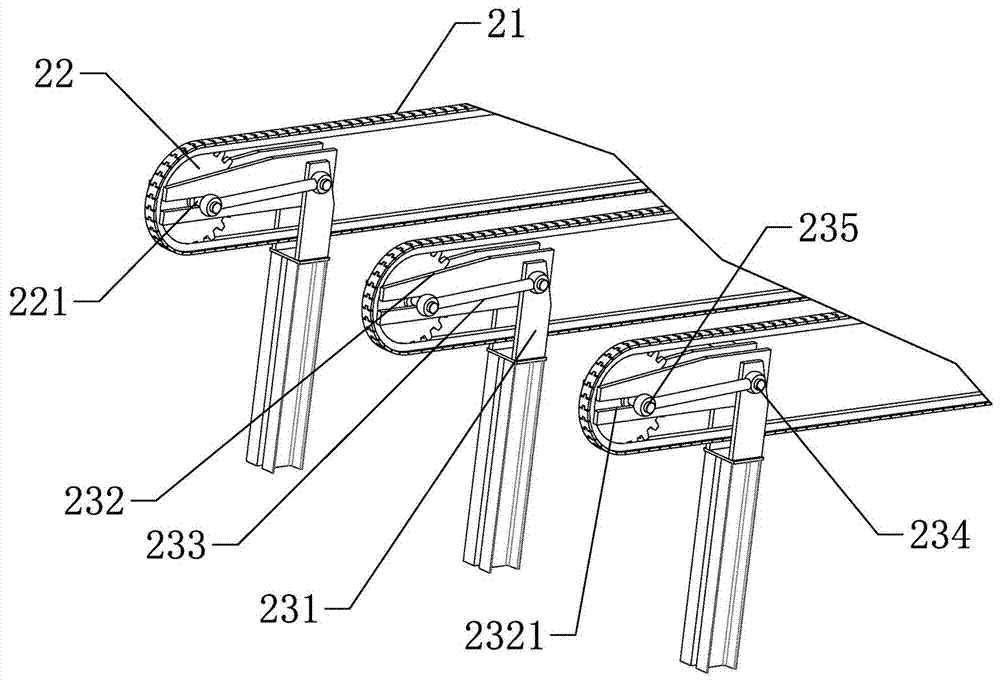

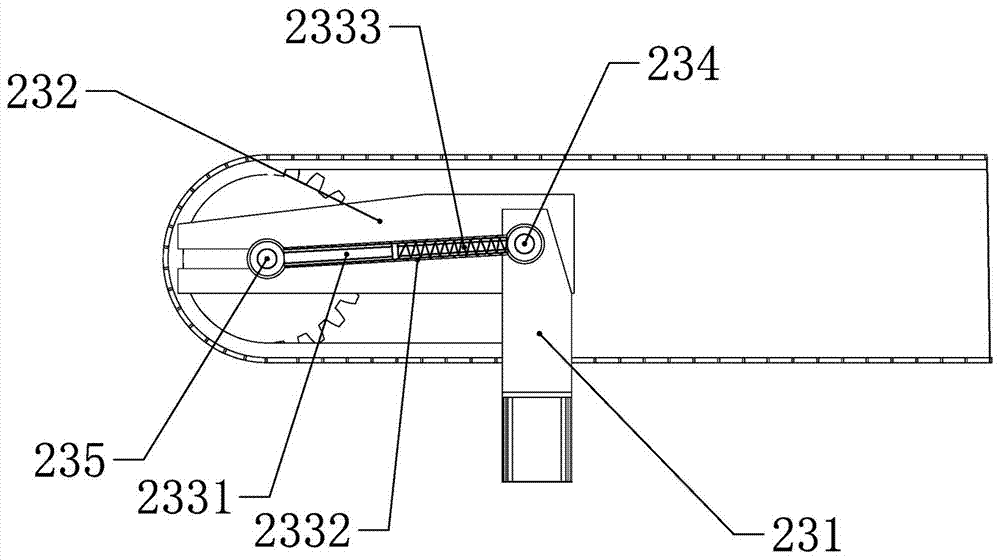

[0028] according to Figure 1 ~ Figure 4 As shown, a material transfer device includes: a straight material rack 1, a translation mechanism 2, a horizontal material rack 3 and a feeding table 4; the straight material rack 1 and the feeding table 4 are located on both sides of the horizontal material rack 3, and the The mechanism 2 runs through the straight material rack 1 and one end extends into the horizontal material rack 3; the straight material rack 1 is used to remove the steel pipe from the annealing furnace, and the translation mechanism 2 is used to translate the steel pipe on the straight material rack 1 to the horizontal material rack 3, the horizontal material rack 3 is used to send the steel pipes into the feeding table 4 in turn.

[0029] according to figure 1 As shown, the straight material rack 1 includes a number of parallel conveying rollers 11 for conveying materials, and a steel frame 12 for supporting the conveying rollers 11; the translation mechanism 2 ...

Embodiment 2

[0035] The difference from the above-mentioned embodiment 1 is that there are two sets of conveying rollers 11, and the straight material frame 1 includes 2 to 6 sets of conveying rollers 11, and the conveying rollers 11 can be freely increased or decreased according to the length of the steel pipe through the grouped conveying rollers 11. group, to realize the function of adjusting the length of the straight material rack 1, and save the working space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com