Full-automatic program optimization algorithm of bin storage crane

A program optimization, crane technology, applied in the direction of electrical program control, sequence/logic controller program control, calculation, etc., can solve problems such as low efficiency, easy fatigue, damage to warehouse items, etc., to improve operating efficiency and improve operation High efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation process of the present invention is described as follows below:

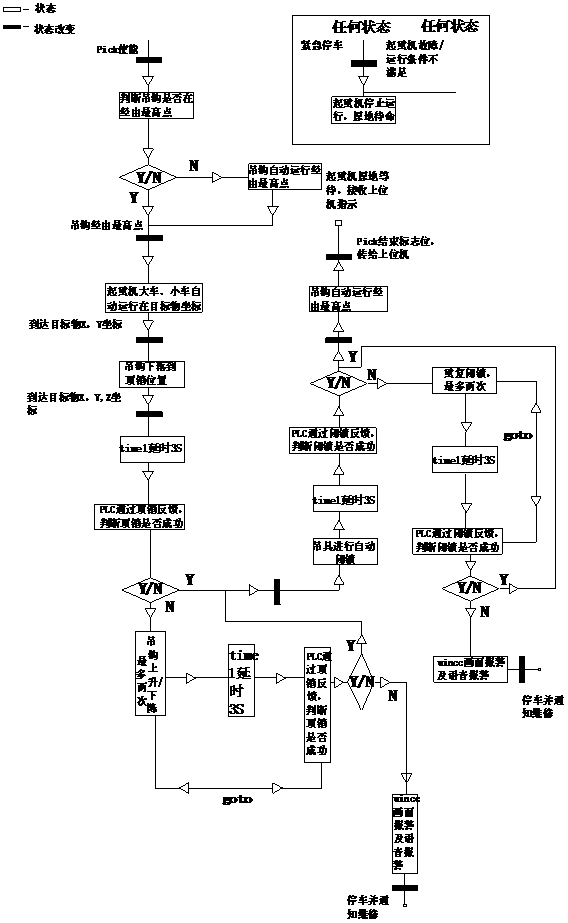

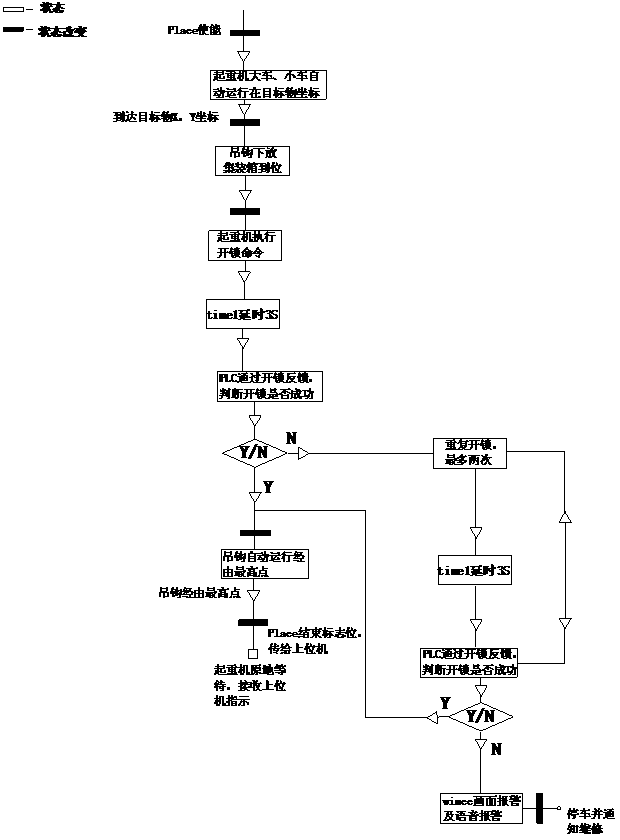

[0019] A fully automatic program optimization algorithm for storage cranes, which includes a Pick process and a Place process, including the following steps:

[0020] 1) Establish a mathematical model: create a mathematical model of the step-by-step approximation method, and perform a one-key positioning function for the crane, so that the crane can run to the highest point before the operation, and there is no callback positioning of the crane; a mathematical function model is established to automatically generate the crane every time it runs The passing point and route of the path, so that every time the crane is working, the hook can safely lift the goods according to the set operating route;

[0021] 2) Development of PLC program: Design an open program to enable the crane to receive the guidance of the running path of the upper computer, automatically complete the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com