Lattice box type mild steel damper

A mild steel damper and box-type technology, which is applied in construction, building components, bridge construction, etc., can solve the problems of low energy consumption efficiency, inability to dissipate energy at the same time, and inability to achieve two-way energy dissipation and shock absorption. High energy efficiency, simple structure and full hysteresis curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

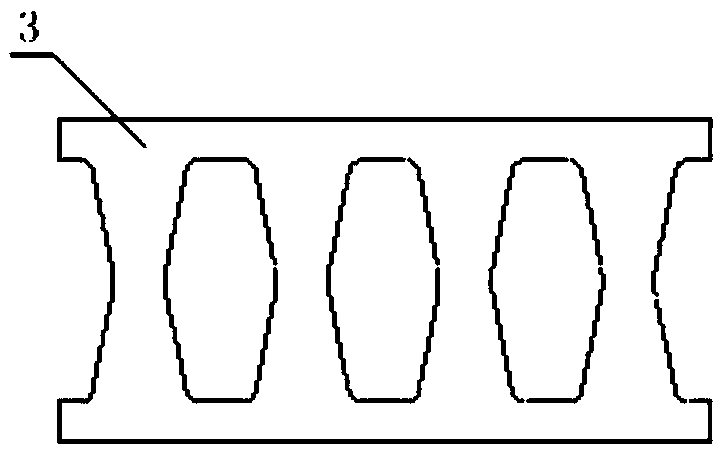

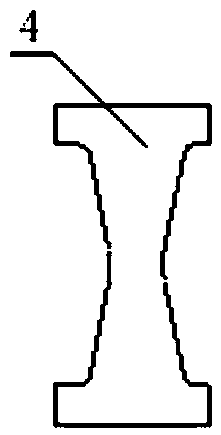

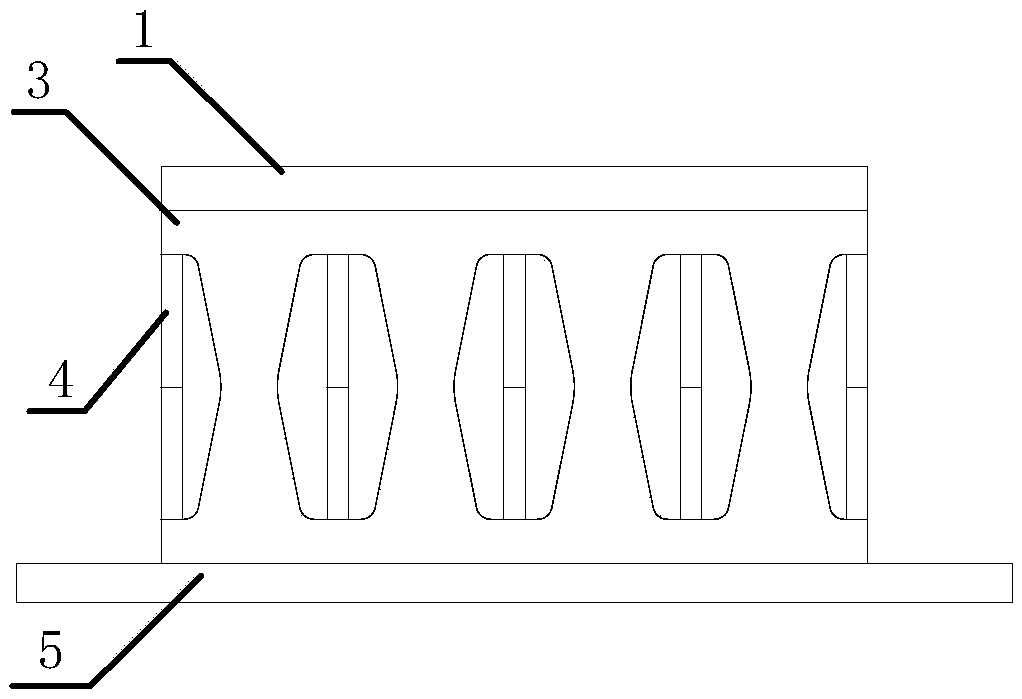

[0023] See 1-4 for the structural diagram of the palace-style box-type mild steel damper.

[0024] Figure 5-6 It is the axonometric drawing of the palace-style box-type mild steel damper. The palace-style box-type mild steel damper includes 1-connecting steel plate, 2-small rectangular (or square) cover plate, 2-1-welding section, 3- It is composed of horizontal hourglass-shaped steel plate, 4-longitudinal hourglass-shaped steel plate, 5-lower connecting steel plate, and 6-bolt hole.

[0025] image 3 The horizontal hourglass-shaped soft steel plates a, b, c, d are placed at equal intervals in the horizontal direction, and the longitudinal steel plates e, f, g, h, i, j, k, l, m, n, o, p, q, r, s, The t and transverse steel plates are placed alternately to form a palace-shaped structure, and the joints are welded with fillet welds. The horizontal steel plate and the longitudinal steel plate form sixteen "mouth" characters, above which are covered by sixteen small rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com