Installation method of triangular base of continuous rolling mill in steel pipe plant

A technology of a triangular base and an installation method, which is applied in the directions of measuring devices, measuring instruments, instruments, etc., can solve the problems such as the inability to measure the elevation and the center position, the inability of the triangular base to meet the continuous production process of steel pipe rolling, and affecting the normal operation of the continuous rolling mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

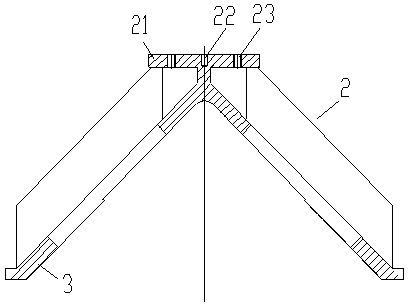

[0023] Such as figure 2 As shown, the installation and measurement tool for the triangular base of the continuous rolling mill in the steel pipe plant of the present invention includes a horizontal plate 21 and a V-shaped plate 3, the horizontal plate 21 is centrally located at the top of the V-shaped plate 3, and the top surface of the horizontal plate 21 is along the axis Two rolling center reference holes 22 are arranged at intervals, and the included angle of the V-shaped plate 3 is a right angle.

[0024] Further, the flatness of the top surface of the horizontal plate 21 is 0.03mm, the surface roughness is Ra0.8μm, the flatness of the two sides of the horizontal plate 21 is 0.03mm, the symmetry is 0.03mm, and the surface roughness is Ra0.8μm .

[0025] Further, the flatness of the inner surface of the V-shaped plate 3 is 0.03 mm, the surface roughness is Ra0.8 μm, and the symmetry of the two sides of the V-shaped plate 3 is 0.03 mm.

[0026] Further, the horizontal pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com