Permanent-magnetic liquid metal flowmeter

A liquid metal, flowmeter technology, applied in the field of flowmeters, can solve the problems that the measurement linearity cannot meet the demand, the online calibration of the flowmeter is not considered, and the temperature change range is wide, so as to increase the uniform area range, improve the output linearity, Solve the effect of inconvenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

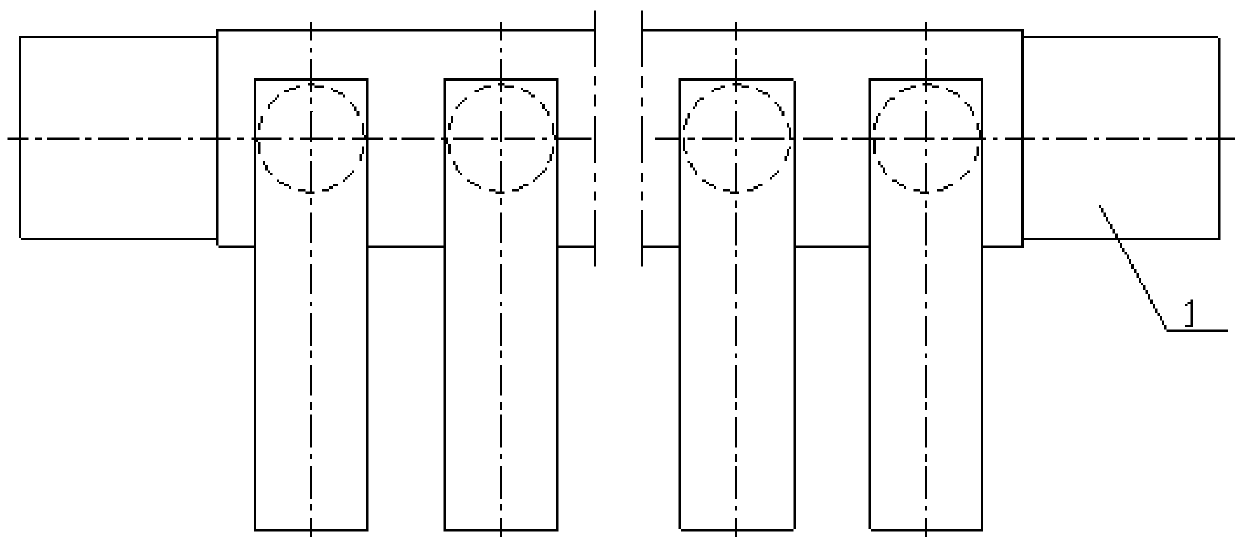

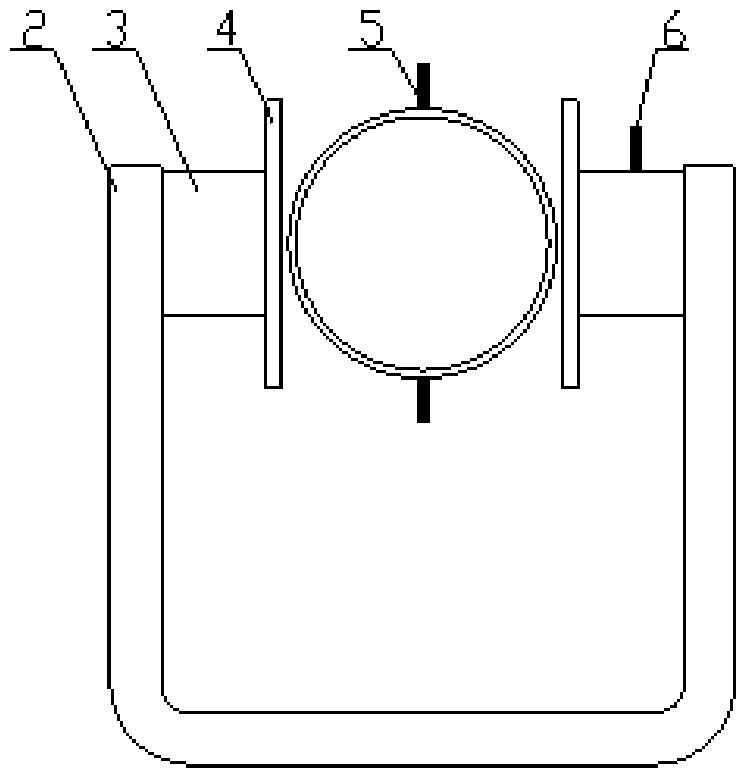

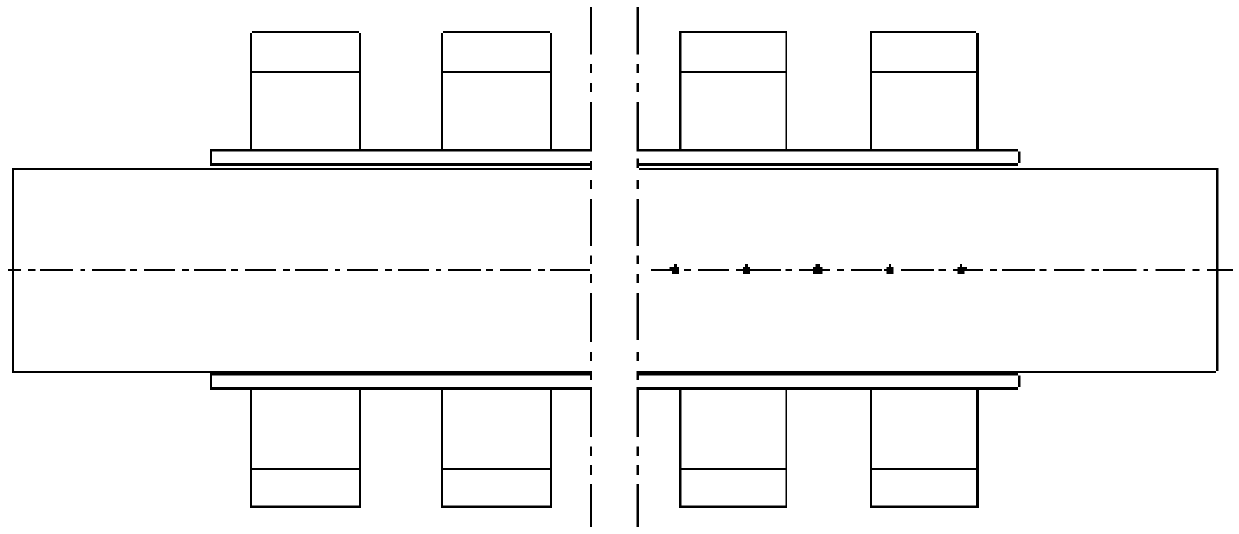

[0051] A permanent magnet liquid metal flowmeter, the flowmeter includes a primary sensor, a secondary instrument and a flow measuring device of a related method;

[0052]The primary sensor includes a magnetic system measuring part, a temperature measuring part, a supporting positioning assembly and a protective part, wherein the protective part is located outside the magnetic system measuring part and is a bell-shaped structure for the protection of the flowmeter; the upper part of the protective part is also There is a magnetic flux measurement blind tube, which is used as a magnetic flux density measurement interface for placing the Tesla meter; during regular calibration, extend the Tesla meter to the bottom of the dead tube to ensure the measurement position of the Tesla meter probe at different times After the magnetic flux density measurement of the magnetic steel assembly is completed, the change in the graduation characteristic of the flowmeter caused by the change of ...

Embodiment 2

[0059] Different from Embodiment 1, there is an air gap between the magnetic pole 4 and the pipe assembly 1, and the width of the gap is 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com