Imaging method and imaging apparatus for visual inspection of lower surface of sheet material

A technology of visual inspection and imaging method, which is applied in the direction of measuring device, material analysis, material analysis through optical means, etc. It can solve problems such as inability to accurately reflect the passing state of the strip, insertion into the inner side of the roller table, and malfunction of the flap. Achieve the effect of avoiding blind spots in visual inspection, avoiding unsafe factors, and ensuring safe passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

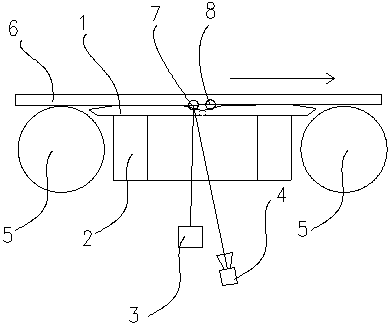

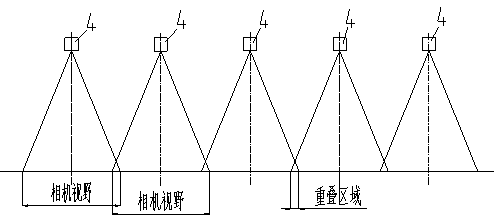

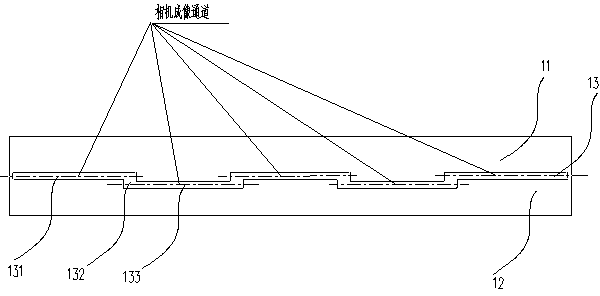

[0021] see Figure 1 to Figure 3 , an imaging method for visual inspection of the lower surface of a plate, aligning several cameras 4 and several lighting sources 3 with a through-slot 13 opened on the guide plate 1 for imaging, and the through-slot 13 is arranged in a staggered manner and runs through , the camera 4 and the lighting source 3 are located below the guide plate channel 13, and the guide plate 1 is fixedly installed between two rollers 5 of the roller table. The through groove 13 becomes a camera imaging channel, and the camera 4 performs imaging detection on the lower surface of the plate 6 passing through the through groove 13 of the guide plate.

[0022] The camera 4 and the illumination light source 3 are combined and paired to form an image, and the imaging field of view covers each section of the channel in the through gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com