Novel rubber drying room

A new type of technology for drying glue room, applied in instruments, control/regulation systems, temperature control, etc., can solve the problems of natural rubber waste steam, manual inspection for a long time, natural rubber can not meet the temperature requirements, etc., to achieve a reasonable and practical design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

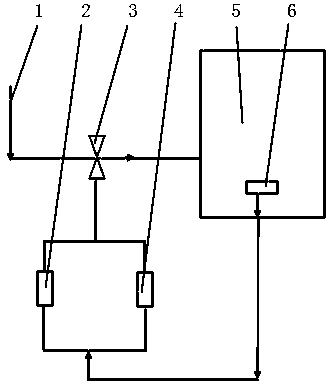

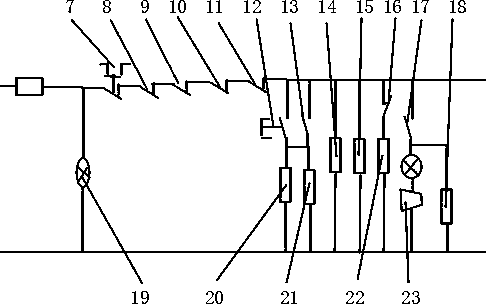

[0008] like figure 1 , figure 2 As shown, the new rubber drying room is mainly composed of steam pipeline 1, microcomputer time control relay 2, high temperature resistant solenoid valve 3, intelligent temperature control instrument 4, platinum resistance 5, rubber drying room 6, steam solenoid valve thermal protection normally closed contact 7. Emergency stop button 8, time relay normally closed contact 9, thermocouple temperature measurement and normally closed contact 10, temperature acquisition and normally closed contact 11, start button 12, steam solenoid valve normally open contact 13, temperature acquisition And temperature sensor 14, thermocouple relay coil 15, alarm normally closed contact 16, time relay normally open contact 17, alarm relay coil 18, power indicator light 19, steam solenoid valve running coil 20, time relay coil 21, door The lock relay coil 22 and the glue-drying completion alarm 23 are composed; the platinum resistance 5 is placed in the glue-dryi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap