Compressor electrical box and compressor with same

A technology for compressors and electrical boxes, applied in the field of compressors and compressor electrical boxes, can solve the problems of metal corrosion, affecting the safety performance of equipment, unavoidable electrical safety hazards, etc., to improve the surface temperature, avoid electrical safety hazards, and eliminate Effects of condensation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

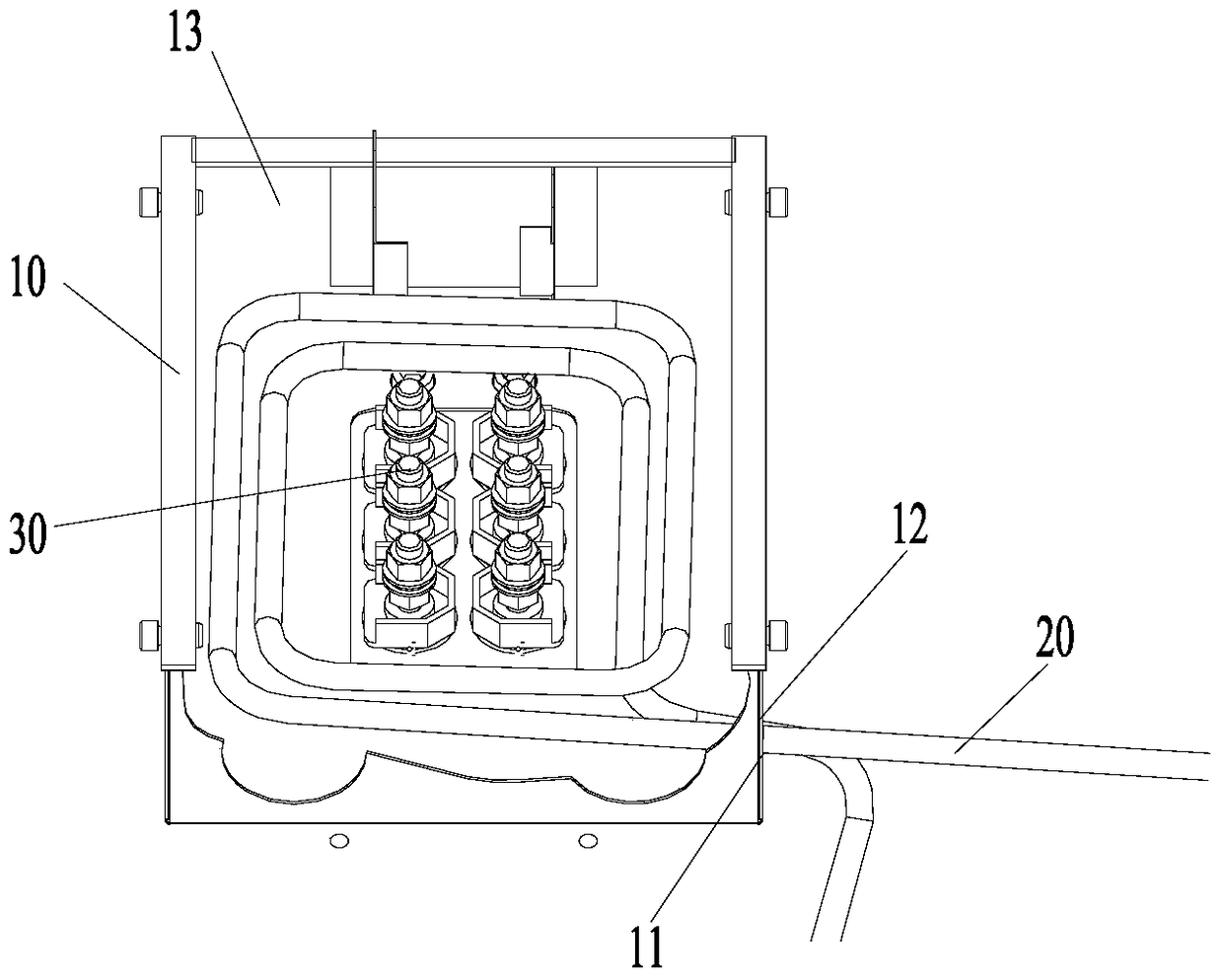

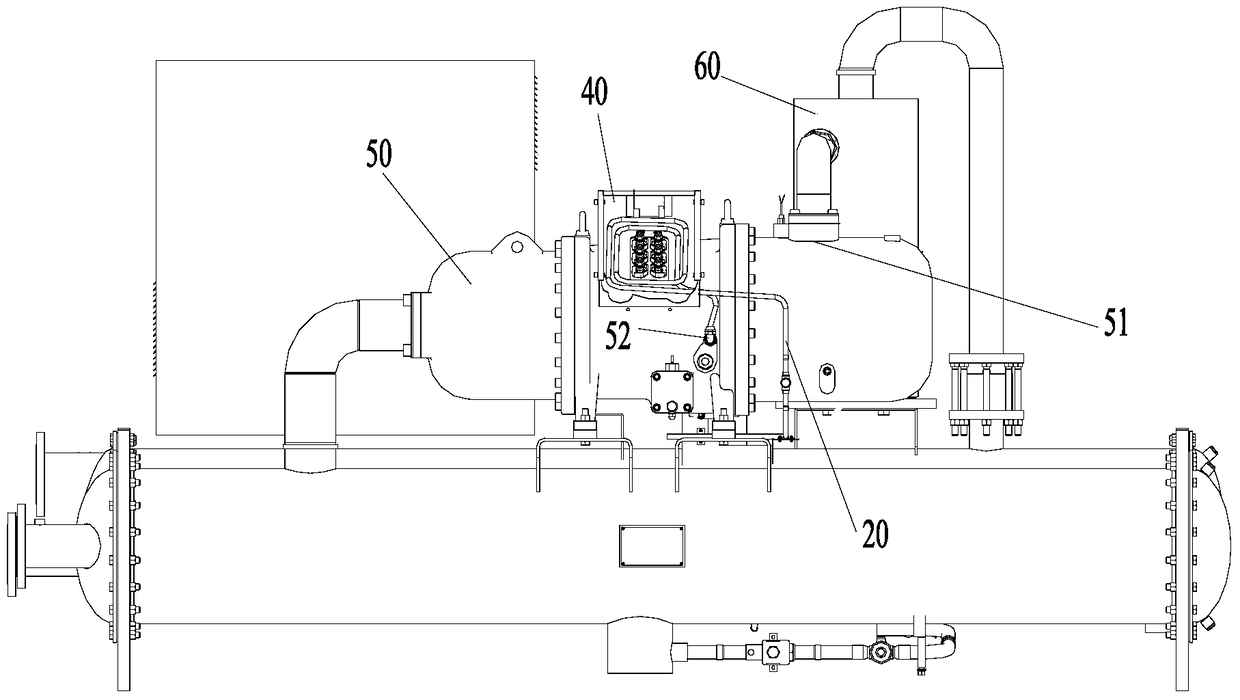

[0022] like figure 1 As shown, the present invention provides a compressor electrical box. Specifically, the electrical box of the compressor includes a box body 10 and a heat source pipe 20 . Wherein, the box body 10 is provided with a heat source tube inlet 11 and a heat source tube outlet 12, at least part of the heat source tube 20 is arranged in the box body 10, and the heat source tube 20 has an extending end pierced into the heat source tube inlet 11 and extending out of the heat source tube outlet 12 extends out to form a heat exchange area in the box body 10.

[0023] The heat source tube 20 forms a heat exchange area in the box body 10 to increase the surface temperature of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com