Judgment method of bonding behavior between continuous casting slab and crystallizer copper plate

A crystallizer copper plate and judgment method technology, applied in the field of metallurgical continuous casting technology, can solve the problems of not considering the response time and timeliness of bonding alarm, lack of example verification and comparative analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

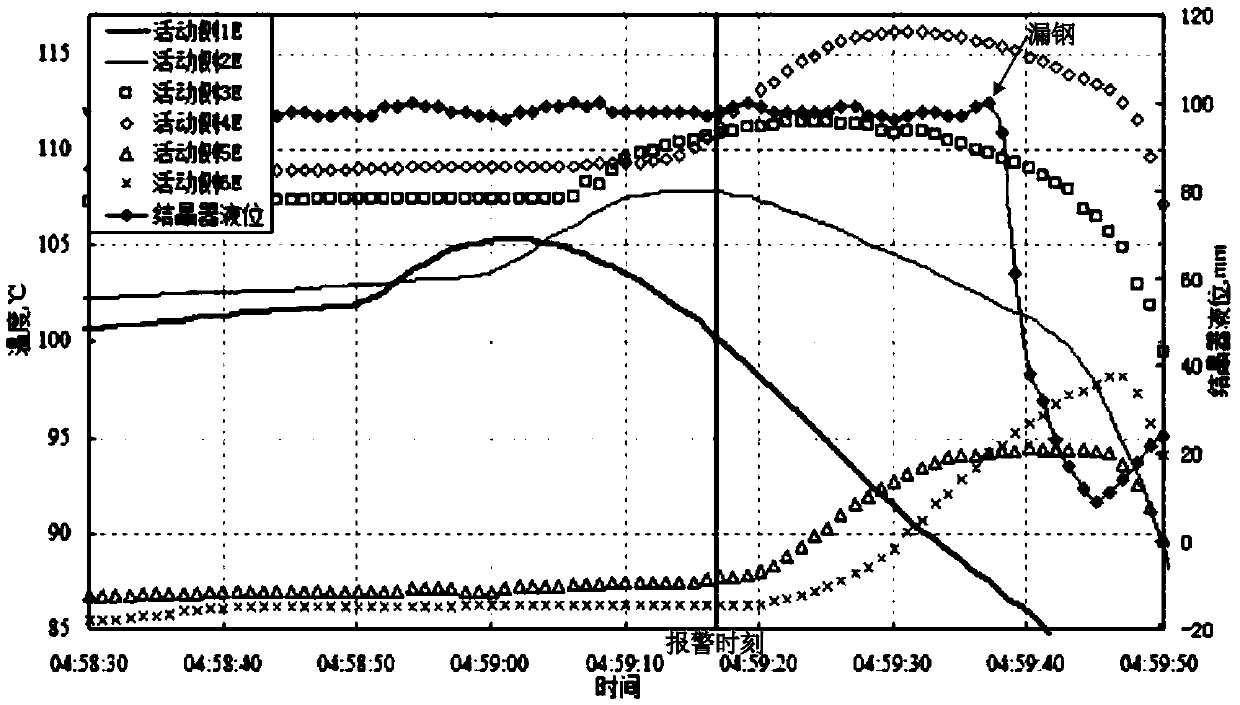

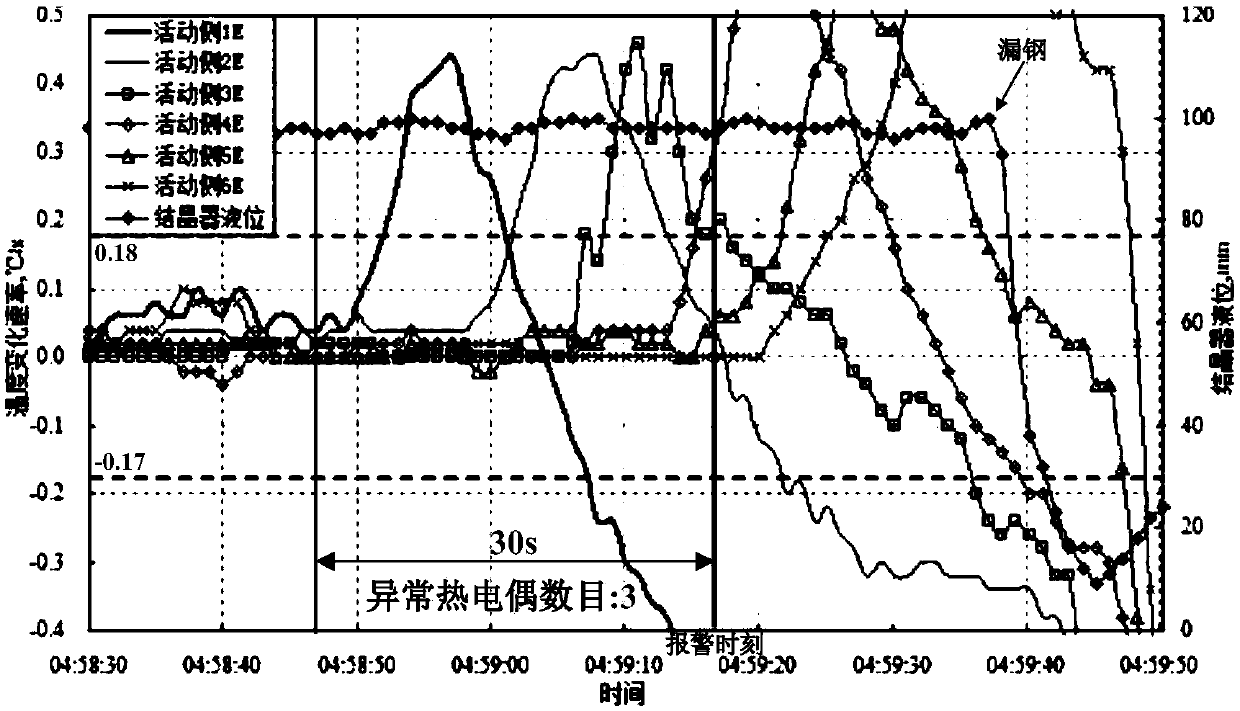

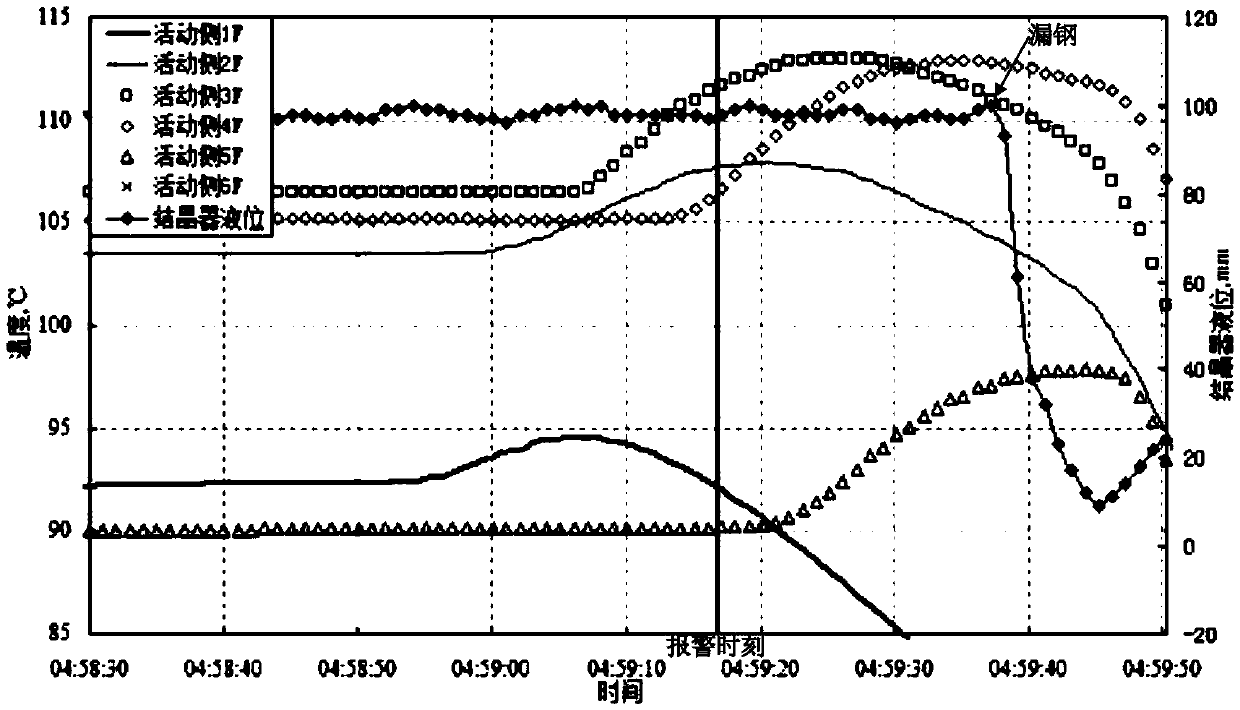

[0097] According to the specific condition of the slab continuous casting machine, the section of the slab is 230×(900~2150)mm 2 , the maximum casting speed is 2.03m / min, the fixed side (outer arc) and the movable side (inner arc) of the crystallizer are respectively buried with 6 rows and 12 columns of wide-faced copper plates, and a total of 72 thermocouples are buried respectively, and the left and right narrow-faced copper plates are respectively buried There are 12 thermocouples in 6 rows and 2 columns, and a total of 168 thermocouples are buried. At the same time, each thermocouple is numbered and marked. The row numbers are recorded as 1, 2, ..., 6 from top to bottom, and the column numbers are from left to The right is recorded as A, B, ..., L in turn, for example, 6G means the thermocouple in row 6 and column G. The calculation process of specific examples will be described below through the method for judging the bonding behavior of the continuous casting slab and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com