Scaling ladder engineering machinery and ladder assembly of scaling ladder engineering machinery

A technology of construction machinery and ladder frames, which is applied in the direction of ladders, buildings, building structures, etc., can solve problems such as sticking, low production efficiency, and high cost, and achieve the goal of reducing hidden dangers of sticking, improving utilization rate, and improving smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The core of the present invention is to provide an aerial ladder construction machine and its ladder frame. The ladder frame has relatively smooth expansion and contraction, can reduce the hidden danger of sticking, and can improve the utilization rate of the section.

[0034] This article takes the open truss ladder frame as an example to introduce the technical solution. Those skilled in the art should understand that the concept of the ladder frame described herein can be applied to other forms of ladder frames within the protection scope of this article.

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

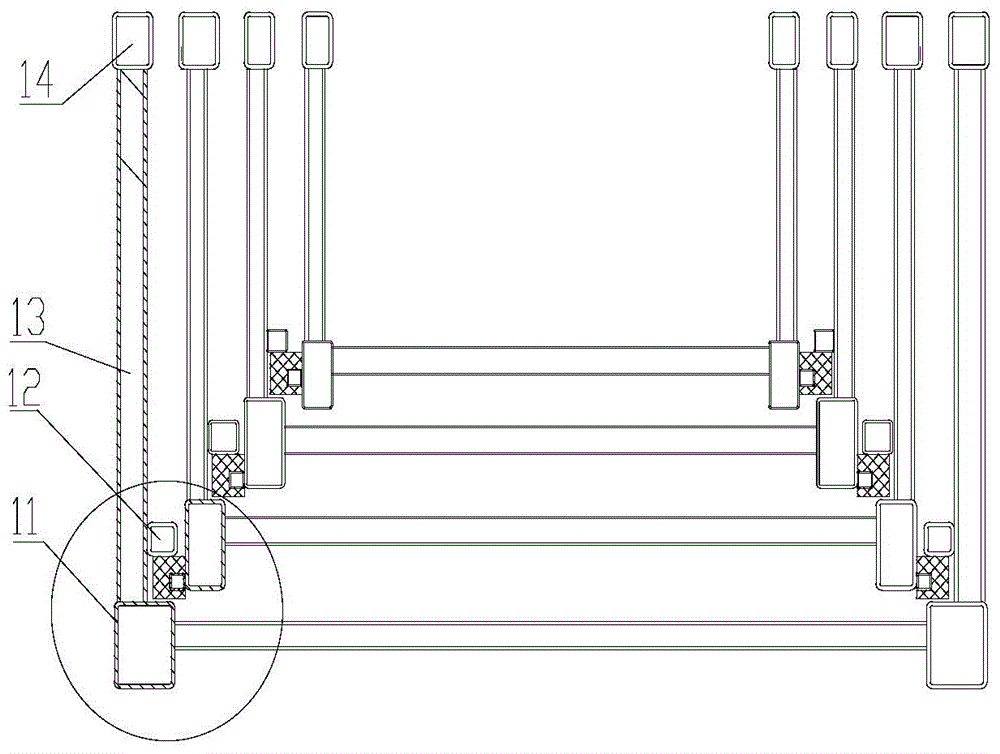

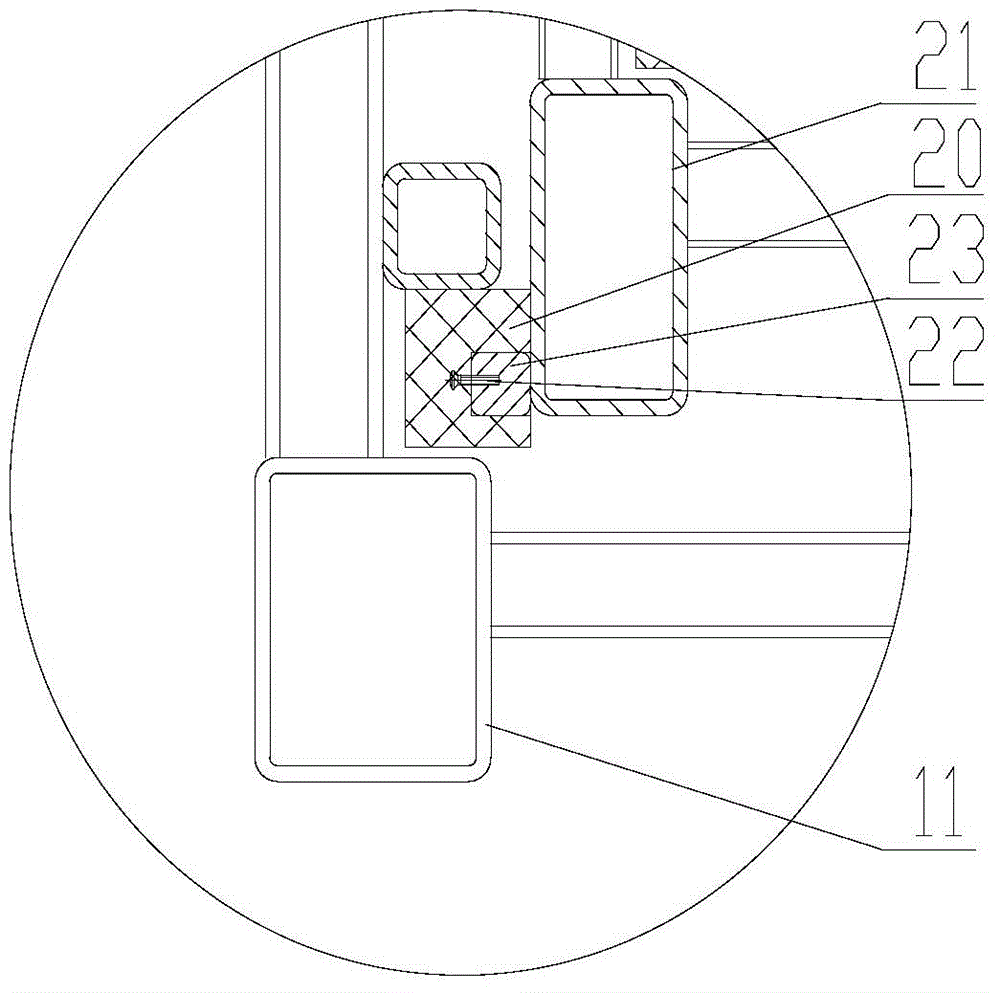

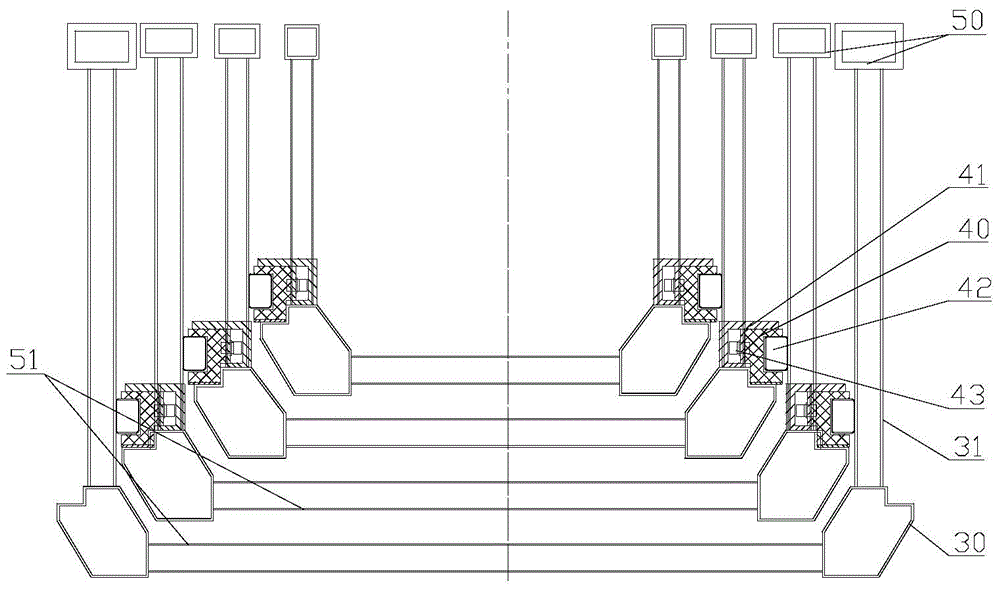

[0036] Please refer to Figure 3-4 , image 3 It is a structural schematic diagram of the ladder frame in the first specific embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com