Valveless electrostatic micropump with low reverse drive voltage and double-sided pump diaphragms, and preparation method thereof

A low driving voltage and side pump technology, applied in the field of microfluidics, can solve problems such as elongated distance between electrodes, excessive driving voltage, and increased driving voltage, so as to increase pump output, reduce driving voltage, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

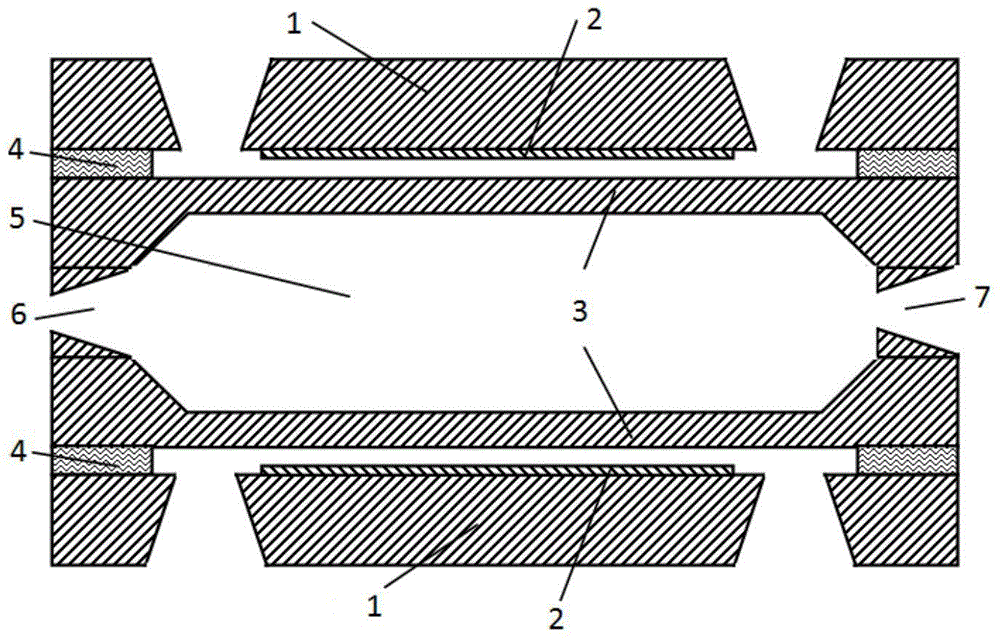

[0024] A reverse low drive voltage double-sided pump membrane valveless electrostatic micropump, its structure is as follows figure 1 shown. The electrostatic micropump has a vertically symmetrical structure with the pump chamber 5 as the axis of symmetry. The upper and lower sides of the pump chamber 5 are drive units respectively, and the left and right ends are respectively an inlet 6 and an outlet 7; The electrode 1, the insulating layer 2, the isolation layer 4 and the pump membrane 3 are fixed, and the interior of the isolation layer 4 is a discontinuous structure to form a drive unit cavity to ensure the vibration space of the pump membrane 3.

[0025] The material of the fixed electrode 1 is Si with a thickness of 50 μm; the material of the insulating layer 2 is SiO 2 , with a thickness of 10 μm; the material of the pump membrane 3 is Si, with a thickness of 10 μm; the material of the isolation layer 4 is SiO 2 , the thickness is 30μm; the natural frequency of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com