Quasi-zero stiffness coupling

A quasi-zero stiffness, coupling technology, applied in rigid shaft couplings, couplings, springs/shock absorbers, etc., can solve problems such as complex structure, large size, difficulty in miniaturization, precision, etc., to achieve Compact structure, reduced torsional vibration level, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in combination with specific embodiments.

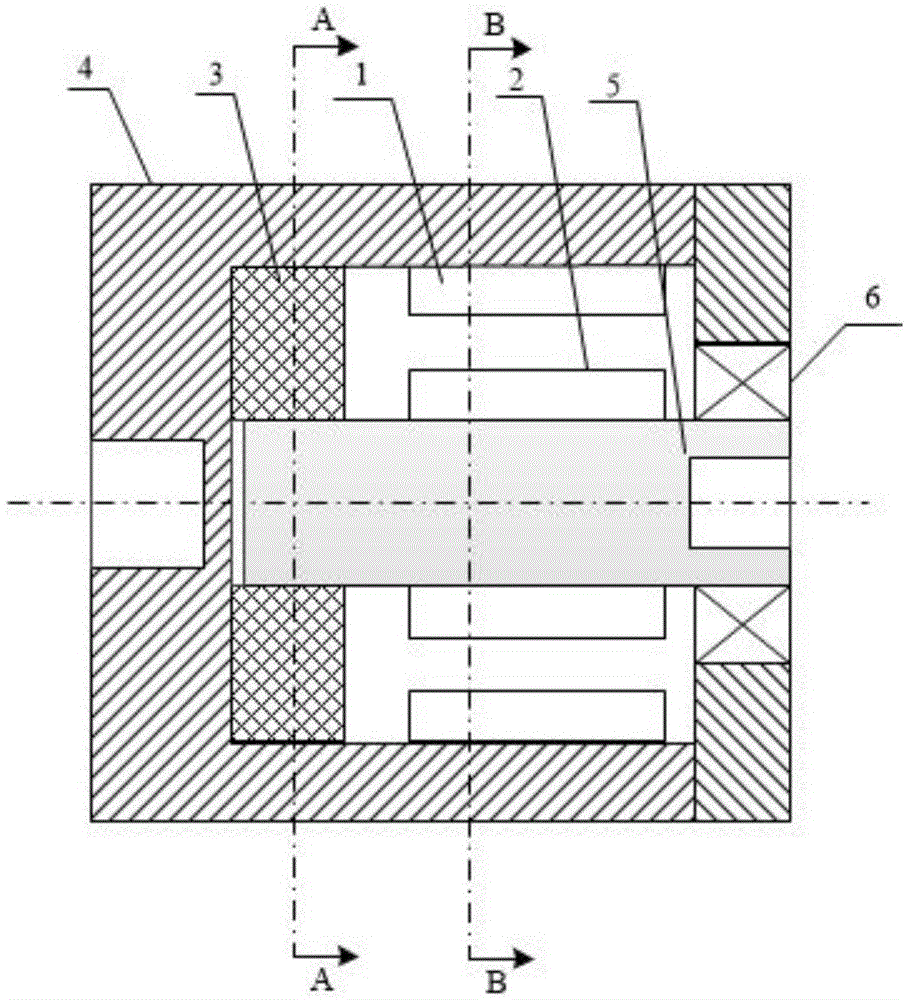

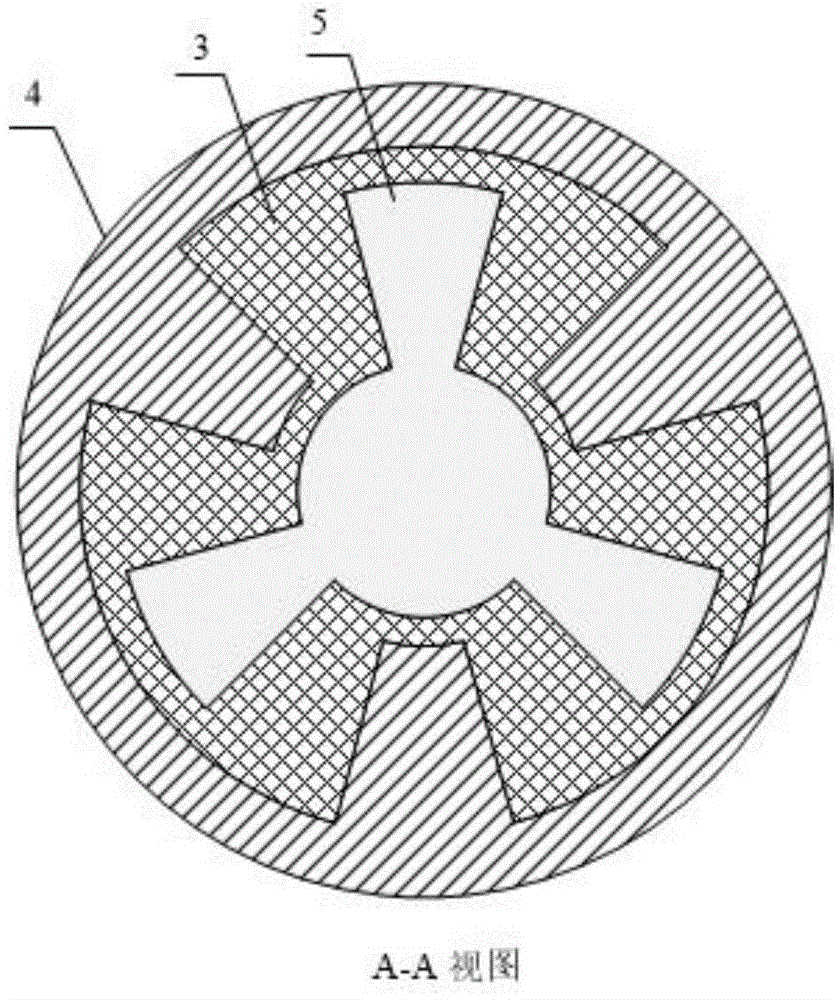

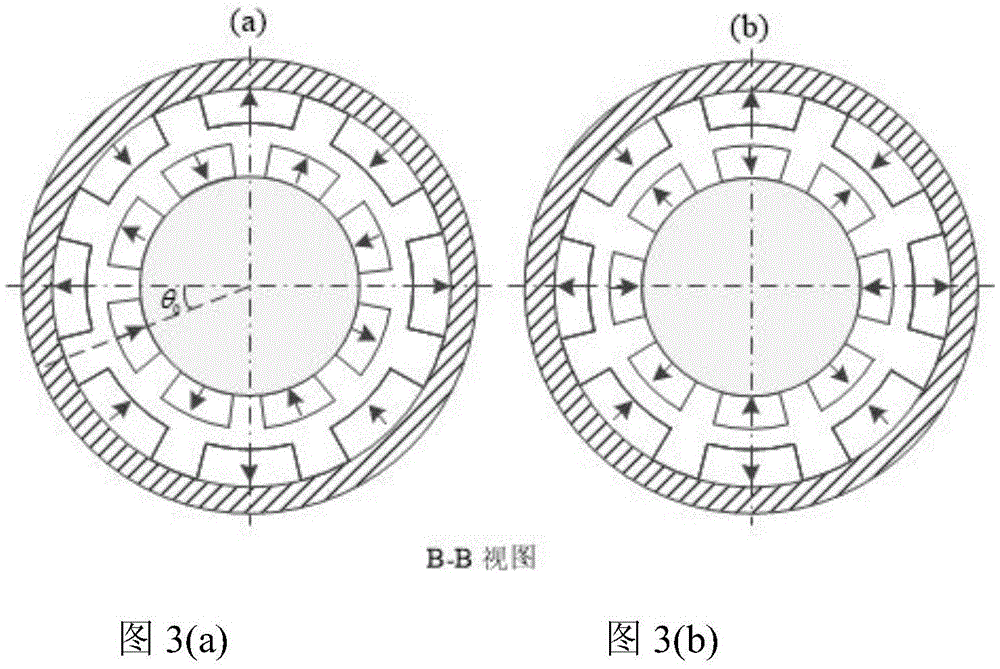

[0024] Such as figure 1 As shown, a quasi-zero stiffness coupling of the present invention includes an outer magnetic ring 1 , an inner magnetic ring 2 , a rubber spring 3 , a housing 4 , an inner shaft 5 and a bearing 6 . The outer magnetic ring 1 can be fixed on the shell 4 and the inner magnetic ring 2 can be fixed on the inner shaft 5 by designing a suitable clamp. The structure of the outer magnetic ring 1 and the inner magnetic ring 2 is as follows image 3 As shown, they are all composed of several magnetic tiles, and the number of magnetic tiles is the same. The magnetization direction of the magnetic tile is along the radial direction and changes alternately. When the outer magnetic ring 1 and the inner magnetic ring 2 are in image 3 In the relative position shown in (b), the magnetic moment generated by the magnetic spring composed of them is zero, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com