Auto-cleaning high-heat-production type flat plate solar collector

A flat-plate heat collector and automatic cleaning technology, which is applied in the field of heat collectors, can solve the problems of limited collector area, limited electric energy, labor-intensive flat-plate heat collectors, etc., and achieves saving transportation and storage time, easy to carry, and fixed Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

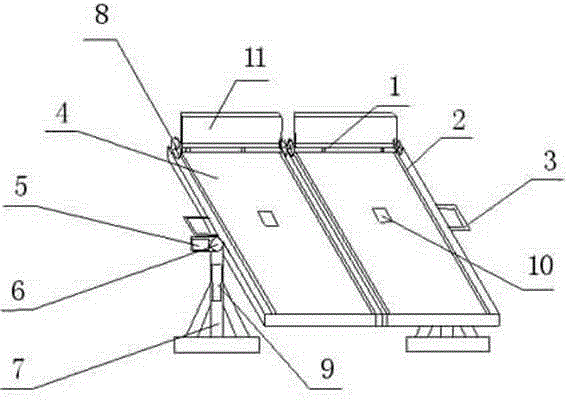

[0018] Further illustrate the present invention below in conjunction with accompanying drawing.

[0019] A self-cleaning and high-heat-producing flat-plate heat collector is characterized in that the flat-plate heat collector body 4 is welded and installed on the frame 7 of the flat-plate heat collector, and the lower end of the frame 7 is a detachable bracket supported by three The shaft forms a triangular structure, handles 3 are provided on both sides of the flat plate heat collector body 4 for carrying, and a transmission device is installed below the horizontal central axis of the frame 7, and the transmission device includes a motor 5 and a rotating shaft 6 , the photosensitive sensor 10 and the timing controller 9, the motor 5 and the rotating shaft 6 are fixedly connected, the photosensitive sensor 10 is connected with the rotating shaft 6 through the timing controller 9, and the motor 5 controls the direction of rotation of the heat collector through the photosensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com