Dynamic calibration method for springs

A dynamic calibration and pending calibration technology, which is applied in the testing of measuring devices, instruments, and mechanical components, can solve the problems of inability to fully reflect the working characteristics of springs, few calibration measurement points, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of spring dynamic calibration method, its concrete steps are:

[0024] The first step is to build a spring dynamic calibration system

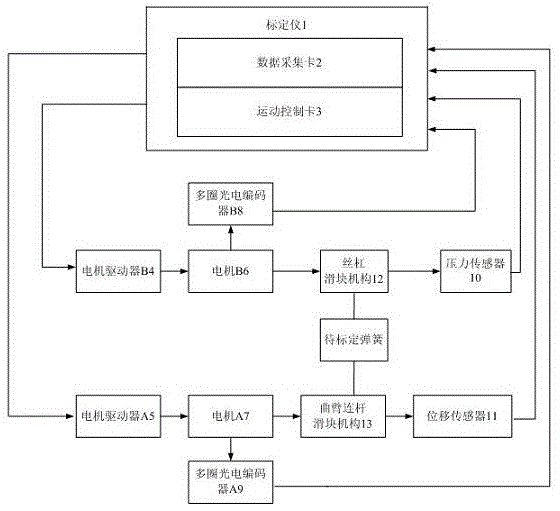

[0025] Spring dynamic calibration system, including: calibration instrument 1, motor driver A5, motor A7, multi-turn photoelectric encoder A9, motor driver B4, motor B6, multi-turn photoelectric encoder B8, crank arm linkage slider mechanism 13, lead screw Slider mechanism 12 , displacement sensor 11 and pressure sensor 10 ; wherein, calibration instrument 1 includes: data acquisition card 2 and motion control card 3 . The output end of the calibration instrument 1 is respectively connected with the input end of the motor driver A5 and the input end of the motor driver B4 through cables; The block mechanism 13 and the multi-turn photoelectric encoder A9 are connected through a rotating shaft, and the output end of the crank arm linkage slider mechanism 13 is connected with the input end of the displacement sensor 11 through a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com