Industrial vehicle

A technology for operating vehicles and operating volume, which is applied in the directions of transmission control, electrical control, belt/chain/gear, etc., and can solve problems such as vehicle shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0106] According to the first embodiment described above, the following effects can be obtained.

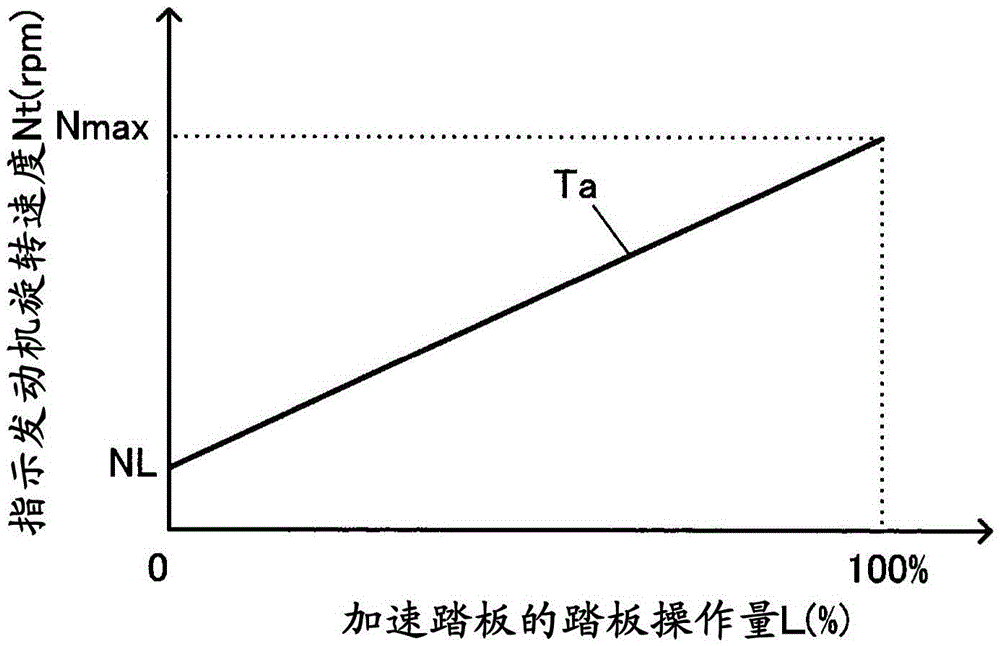

[0107] (1) When the required engine rotational speed Nr is greater than the predetermined value N0, the acceleration Ra of the required engine rotational speed Nr based on the difference between the required engine rotational speed Nr and the actual engine rotational speed Na, in other words, per unit time (for example, 10 ms) Increase the rotation speed to perform calculations. Thereby, it is possible to suppress the jumping-out phenomenon at the time of starting and the occurrence of hunting, so that the transition from deceleration to acceleration can be performed quickly, that is, the traction force can be rapidly increased. Since the ride comfort of the vehicle can be improved, the burden on the operator can be reduced. In addition, it is also possible to improve work efficiency.

[0108] (2) When the accelerator pedal 192 is depressed and operated, when the actual engine ...

Deformed example 1

[0114] In the above-described embodiment, the acceleration and deceleration of the requested engine rotational speed Nr are calculated based on the difference between the requested engine rotational speed Nr and the actual engine rotational speed Na, but the present invention is not limited thereto. The present invention can be configured to calculate only the acceleration of the requested engine rotational speed Nr.

Deformed example 2

[0116] In the above-mentioned embodiment, when the accelerator pedal 192 is depressed and operated, the acceleration Ra (hereinafter referred to as Ra1 ) at which the required engine rotational speed Nr is equal to or less than the predetermined value N0 and the required engine rotational speed Nr are set to be greater than the predetermined value N0 Also, the acceleration Ra (hereinafter referred to as Ra2) when the value obtained by subtracting the required engine speed Nr from the actual engine speed Na is greater than the threshold N1 is Rah, but the present invention is not limited thereto. The acceleration Ra1 and the acceleration Ra2 can be set to different values from each other.

[0117] In the above-described embodiment, when the accelerator pedal 192 is reset, the deceleration Rd (hereinafter, referred to as Rd1 ) when the required engine rotational speed Nr is equal to or less than the predetermined value N0 is set at a predetermined ratio to the required engine r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com