Amber liked nut and processing technology thereof

A kind of processing technology and nut kernel technology, which is applied in the field of amber nut kernel and its processing technology, can solve the problem of single effect and achieve the effect of good appearance, good taste and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

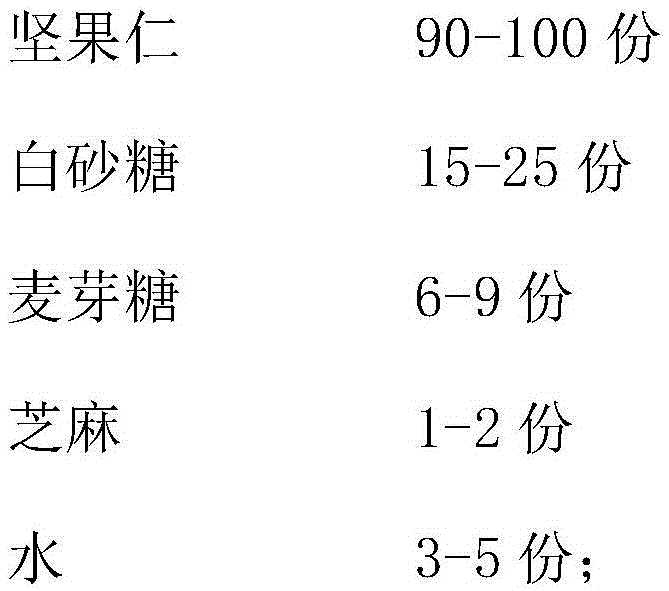

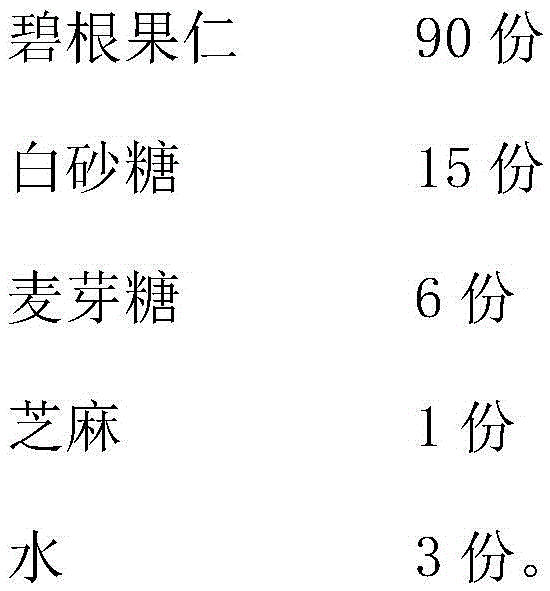

[0023] An amber nut kernel comprises the following raw materials in parts by weight:

[0024]

[0025] A processing technique for amber nut kernels, comprising the following steps:

[0026] (1) Select high-quality pecan nuts and boil them in boiling water for 8 minutes. The water should cover the nuts to remove the bitter taste of the pecan nuts and cook them. Then, let them cool in the air to remove excess water. , to dry the surface of the nuts.

[0027] (2) Mix 15 parts of white sugar, 3 parts of maltose, 1 part of sesame, and 3 parts of water in a stirring fryer, and cook at a temperature of 110°C until the syrup sees obvious foaming , pour the nut kernels into the pot and coat them with sugar.

[0028] (3) Deep-fry the nut kernels obtained after coating sugar in step (2), completely immerse the nut kernels in palm oil, and fry at 120°C for 15 minutes. The kernels are wrapped with maltose; spread out to dry, and the whole process is carried out during the stirring pr...

Embodiment 2

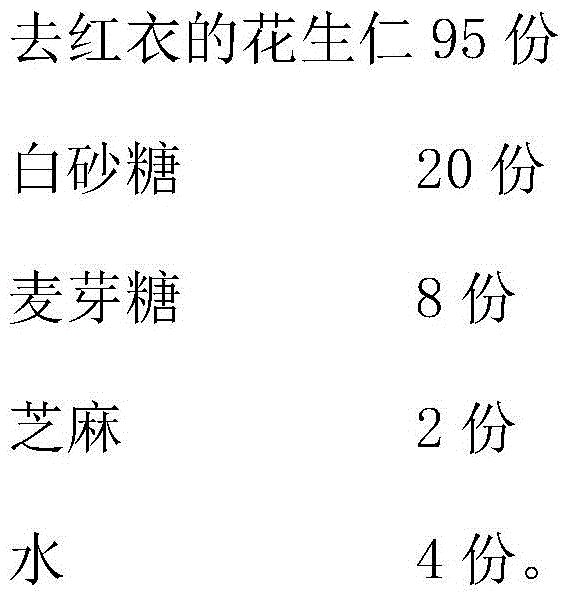

[0031] An amber nut kernel comprises the following raw materials in parts by weight:

[0032]

[0033] A processing technique for amber nut kernels, comprising the following steps:

[0034] (1), select good-quality peanut kernels without red coats;

[0035] (2) Mix 20 parts of white sugar, 4 parts of maltose, 2 parts of sesame seeds, and 4 parts of water in a stirring fryer, and cook at a temperature of 110°C until the syrup sees obvious foaming , pour the nut kernels into the pot and coat them with sugar.

[0036] (3) Deep-fry the nut kernels obtained after coating the sugar in step (2), completely immerse the nut kernels in palm oil, and fry at 125°C for 13 minutes. Before cooking, pour 4 parts of maltose into the oil pan. The kernels are wrapped with maltose; spread out to dry, and the whole process is carried out during the stirring process.

[0037] (4), packaging.

Embodiment 3

[0039] An amber nut kernel comprises the following raw materials in parts by weight:

[0040]

[0041] A processing technique for amber nut kernels, comprising the following steps:

[0042] (1), select almonds of good quality;

[0043] (2) Mix 25 parts of white sugar, 4.5 parts of maltose, 2 parts of sesame seeds, and 5 parts of water in a stirring fryer, and cook at a temperature of 110°C until the syrup shows obvious foaming , pour the nut kernels into the pot and coat them with sugar.

[0044] (3) Deep-fry the nut kernels obtained after coating the sugar in step (2), completely submerge the nut kernels in palm oil, and fry at 120°C for 10 minutes. Before cooking, pour 4.5 parts of maltose into the oil pan, The kernels are wrapped with maltose; spread out to dry, and the whole process is carried out during the stirring process.

[0045] (4), packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com