Slag scraping device of aerated grit chamber

A slag scraping device, aeration sand settling technology, applied in the feeding/discharging device of the sedimentation tank, sedimentation tank, sedimentation separation and other directions, which can solve the problems of accidents, uncontrollable motor lifting slag scrapers, derailment of truss vehicles, etc. , to achieve the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

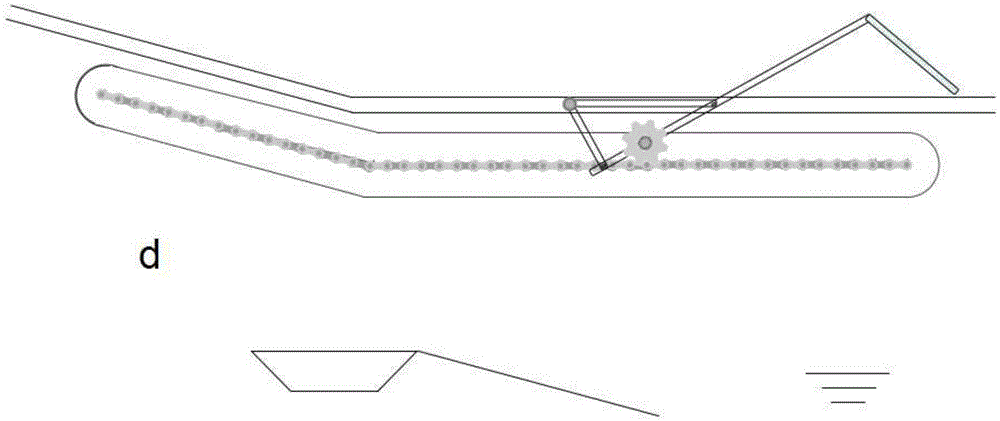

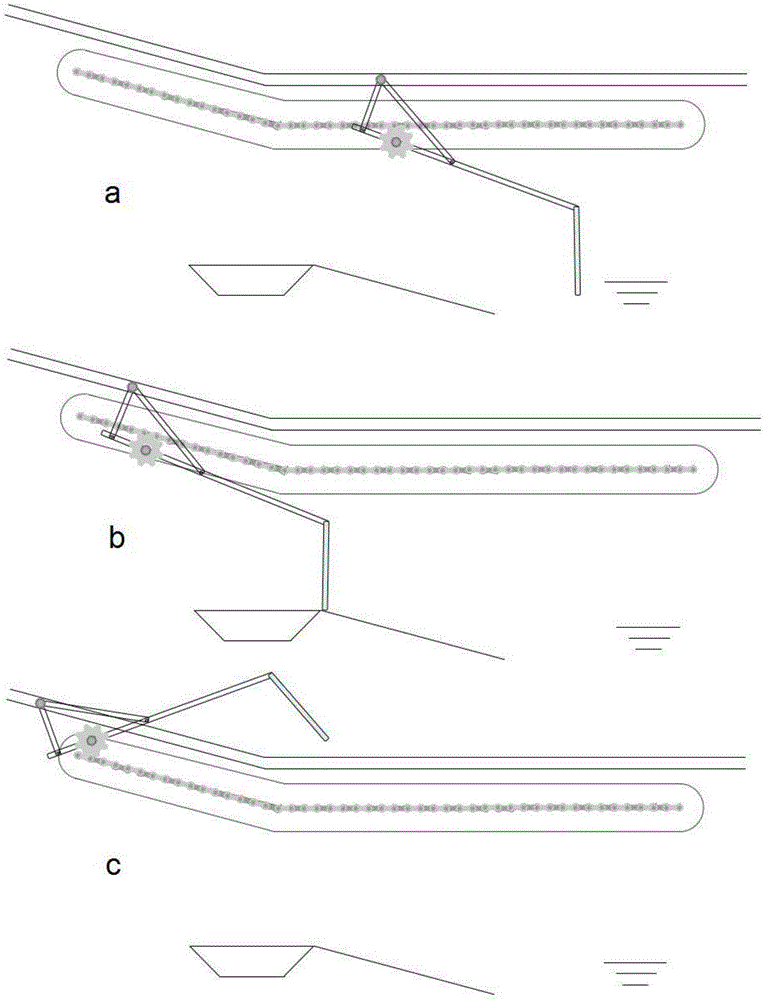

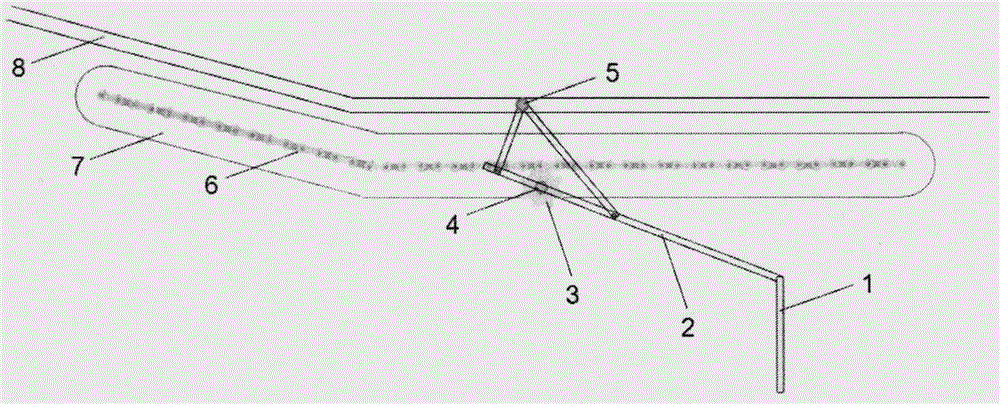

[0014] An embodiment of the present invention is provided below, and a schematic diagram is attached to assist in the description.

[0015] Such as figure 1 As shown, a slag scraping device for an aerated grit chamber includes a scraper 1, a slag scraper arm 2, a travel gear 3, a driving shaft 4, a driven shaft 5, a fixed chain 6, a driving shaft chute 7, and a driven Shaft chute 8. Among them, the scraper 1, the slag scraping arm 2, the travel gear 3, the driving shaft 4, and the driven shaft 5 form the moving parts of the slag scraping device; the fixed chain 6, the driving shaft chute 7, and the driven shaft chute 8 form the scraping Fixed parts of the slag plant. Specifically, the scraper 1 is installed on the slag scraper arm 2, and the installation height and angle can be adjusted as required. The slag scraping arm 2 is connected with the driving shaft 4 and the driven shaft 5 . Wherein the driving shaft 4 moves in the driving shaft chute 7 , and the driven shaft 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com