Heat accumulating type oxidation device for catalysis denitration

A technology for catalytic denitration and oxidation devices, applied in incinerators, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of low efficiency and large area, and achieve low manufacturing and operating costs, reasonable structure, Good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

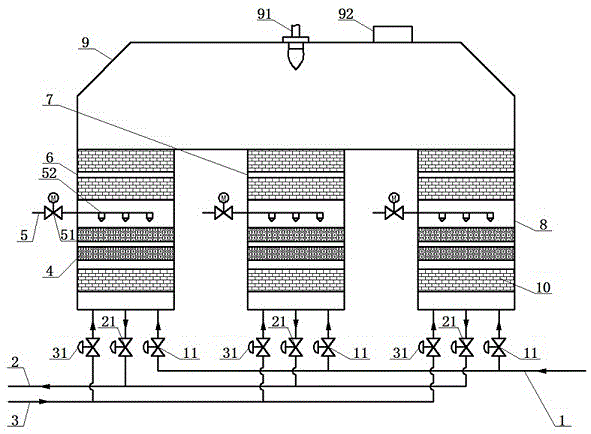

[0014] From figure 1 It can be seen that a regenerative oxidation device for catalytic denitrification includes a first regenerator 6, a second regenerator 7, a third regenerator 8 and an oxidation chamber 9. The oxidation chamber 9 is fixedly installed in the above On the top of the three regenerators, the oxidation chamber 9 is provided with a burner 91 and an explosion-proof door 92, and the explosion-proof door 92 plays a role in releasing pressure during explosion. A regenerator layer 10 is installed inside each regenerator, and below each regenerator is fixedly connected the intake pipe 1, the exhaust pipe 2, the blowback pipe 3, the intake valve 11, the exhaust valve 21, and the blowback Valve 31. Specifically, the intake pipe 1 is divided into three sub-pipes, which are respectively connected to the regenerator 6, the regenerator 7 and the regenerator 8, and the exhaust gas containing VOCs is controlled to enter through the three intake valves 11; the exhaust pipe 2 an...

Embodiment 2

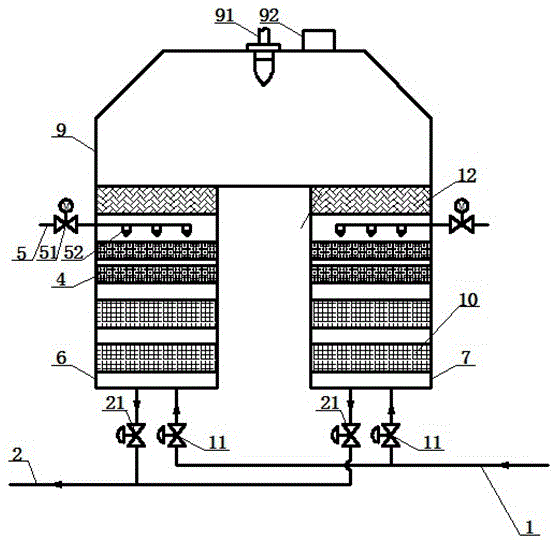

[0026] From figure 2 It can be seen that a regenerative oxidation device for catalytic denitration includes a first regenerator 6, a second regenerator 7 and an oxidation chamber 9. The oxidation chamber 9 is fixedly installed on the top of the two regenerators. , The oxidation chamber 9 is provided with a burner 91 and an explosion-proof door 92, and the explosion-proof door 92 plays a role in releasing pressure during explosion. A regenerator layer 10 is installed inside each regenerator, and an intake pipe 1 and an exhaust pipe 2 are fixedly connected below each regenerator. Specifically: the intake pipe 1 is divided into two sub-pipes, respectively connected to the regenerator 6 and the regenerator 7, and the exhaust gas containing VOCs is controlled to enter through the intake valve 11; the exhaust pipe 2 also passes through the exhaust gas respectively Valve 21 controls the outflow of gas.

[0027] The feature of this embodiment is that each regenerator is also installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com