Single-hole linear jet flow mortar making nozzle

A nozzle and linear technology, which is applied in the field of single-hole linear jet slurry-making nozzles, can solve the problems of affecting filling quality, waste of cementitious materials, and reducing tailings deposition, so as to avoid large-area sand accumulation, facilitate sand accumulation, and improve The effect of filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

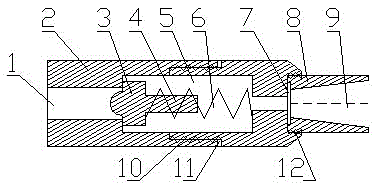

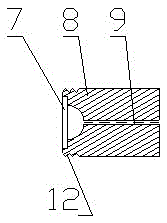

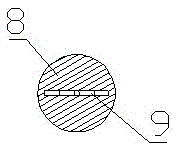

[0019] Referring to the accompanying drawings, this embodiment includes a housing 2, a one-way valve 3, a spring 6 and a nozzle 8, the housing 2 is provided with an air inlet 1 and an air chamber 5; the one-way valve 3 and the spring 6 are installed In the air chamber 5, one end of the spring 6 is connected to the housing 2, and the other end is connected to the one-way valve 3. The one-way valve 3 is provided with a tail rod 4, and the tail rod 4 is located in the spring 6. When the high-pressure air passes through the air inlet 1, it opens the check valve 3 and enters the air chamber 5. The opening and closing state of the check valve 3 is controlled by the spring 6. If there is no high-pressure air supply, the check valve 3 is controlled by the spring 6. Push to the closed state; the nozzle 8 is installed on the housing 2 and communicates with the air chamber 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com