Equal feeding quantity type automatic worm polishing mechanism

An automatic polishing and worm technology, applied to mechanical equipment, components with teeth, gear teeth, etc., can solve problems such as large noise, inconsistent feed rate, abnormal noise of motors, etc., to reduce abnormal noise, improve processing accuracy, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

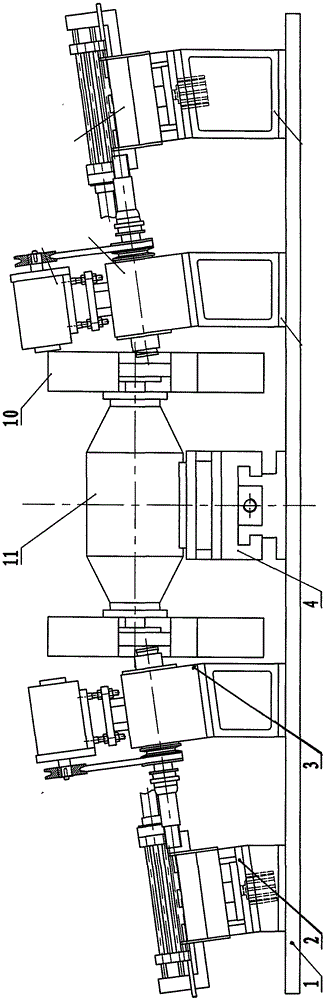

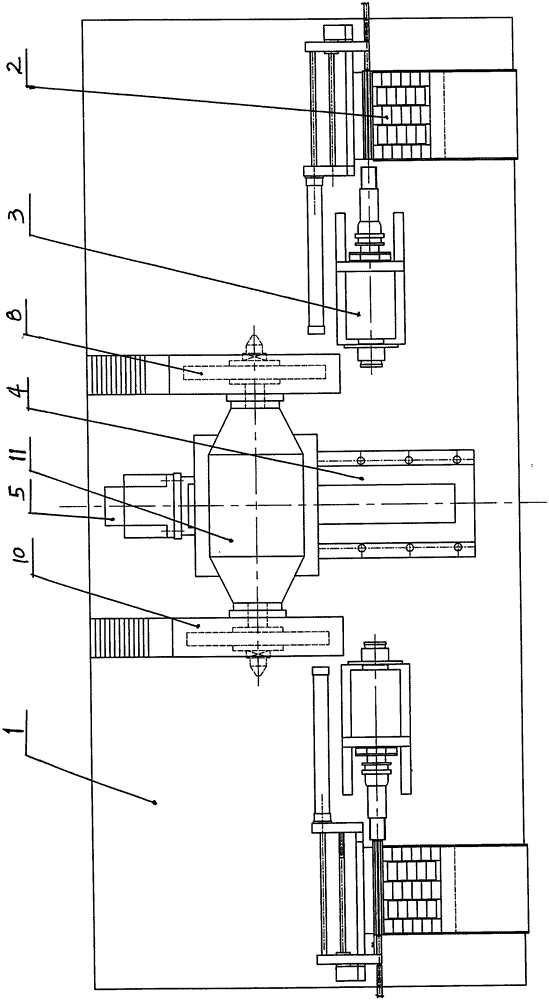

[0009] Reference figure 1 , figure 2 It can be seen that the feed-equal worm automatic polishing mechanism of the present invention includes a worktable 1, a worm polishing device 11, and a worm clamping device 3. The worm clamping device 3 (the worm clamped by it) is inclined to the worm The angle formed by the polishing device 11 (its polishing wheel 8) corresponds to the tooth profile spiral angle of the required polishing worm. The worm polishing device 11 is mounted on the sliding seat 4, which is connected to the sliding seat motor 5 (for Servo motor) is connected.

[0010] Wherein, a feeding device 2 (to realize automatic feeding of the worm) is installed on the worktable 1 and on the side (left and right) of the worm clamping device 3, and the worm polishing device 11 is clamped with the worm A dust extraction device 10 is installed at the intersection of the device 3 (automatic dust extraction for worm polishing). The polishing wheel 8 on the worm polishing device 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com