A valve stem automatic loading device

A technology of automatic loading and valve stem, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of stable and reliable assembly process, high degree of automation, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

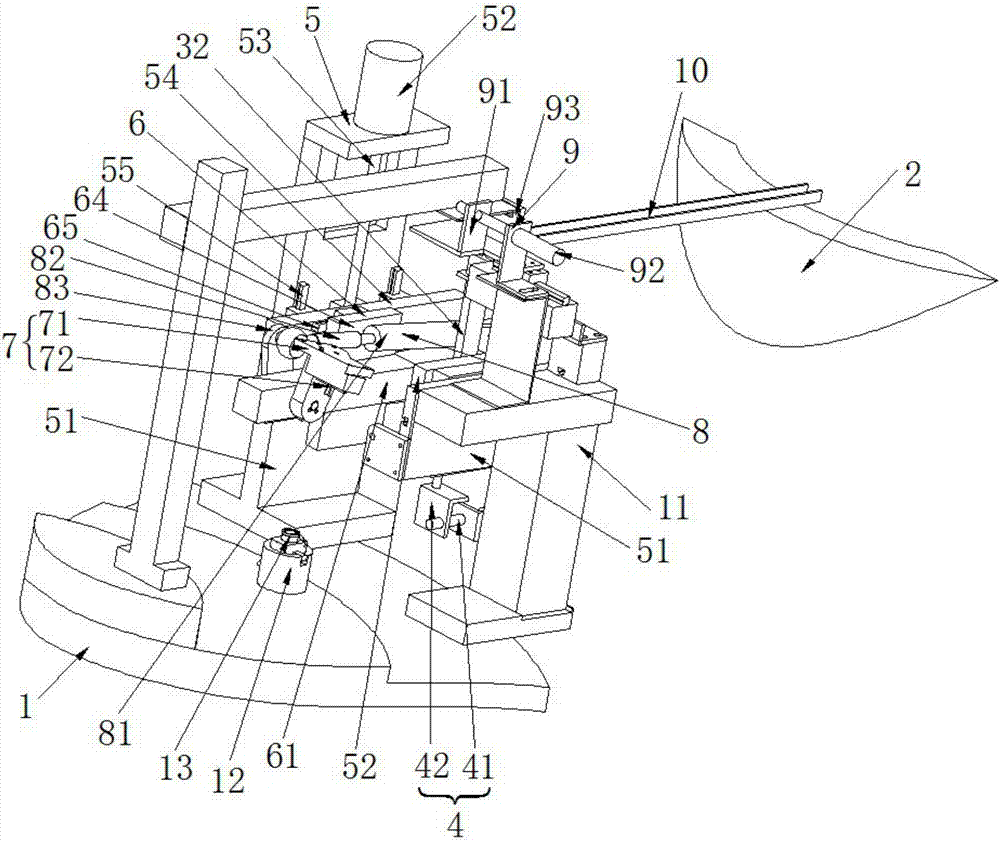

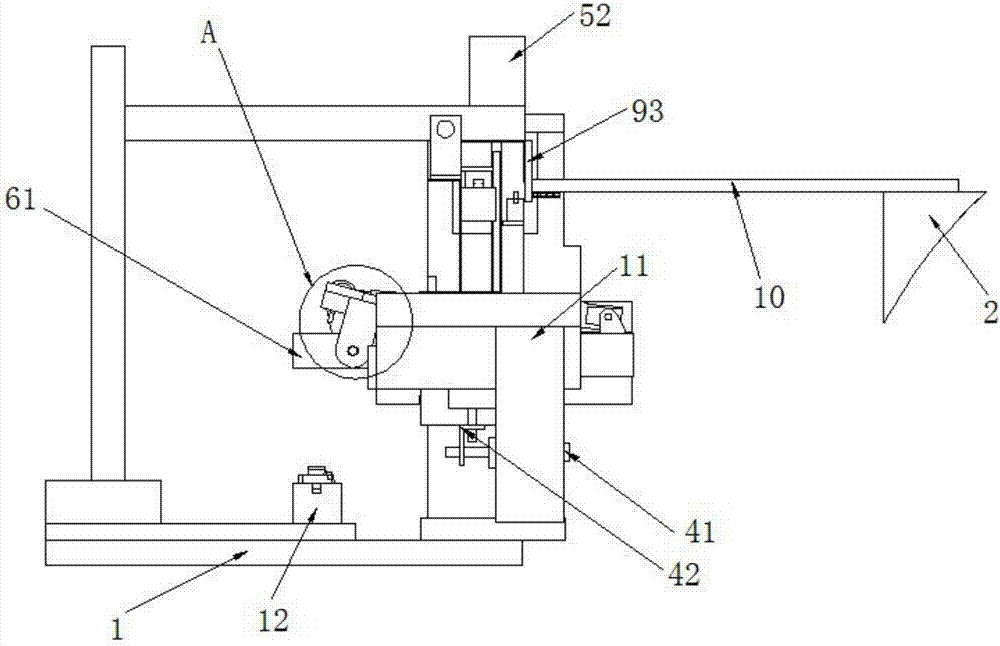

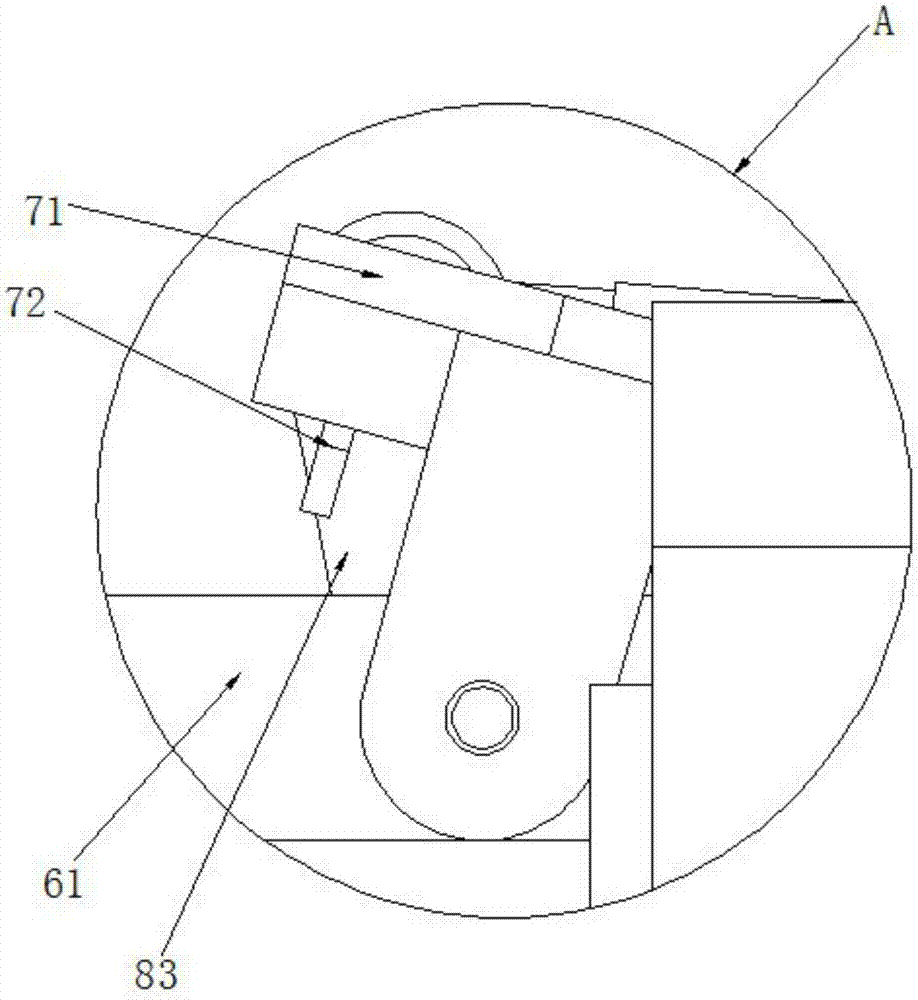

[0060] figure 1 It is a perspective view of the valve stem automatic loading device provided in the embodiment of the present invention; figure 2 It is a front view of the valve stem automatic loading device provided in the embodiment of the present invention; Figure 4 It is a left view of the valve stem automatic loading device provided in the embodiment of the present invention; Figure 6 It is a top view of the valve stem automatic loading device provided in the embodiment of the present invention. Such as figure 1 , 2 , 4, and 6, the valve stem automatic loading device provided in this embodiment includes: a base 1, a quick mold change fixture 12, a vibrating plate 2, a feeding assembly 3, a first clamping assembly 31, a The pushing assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com