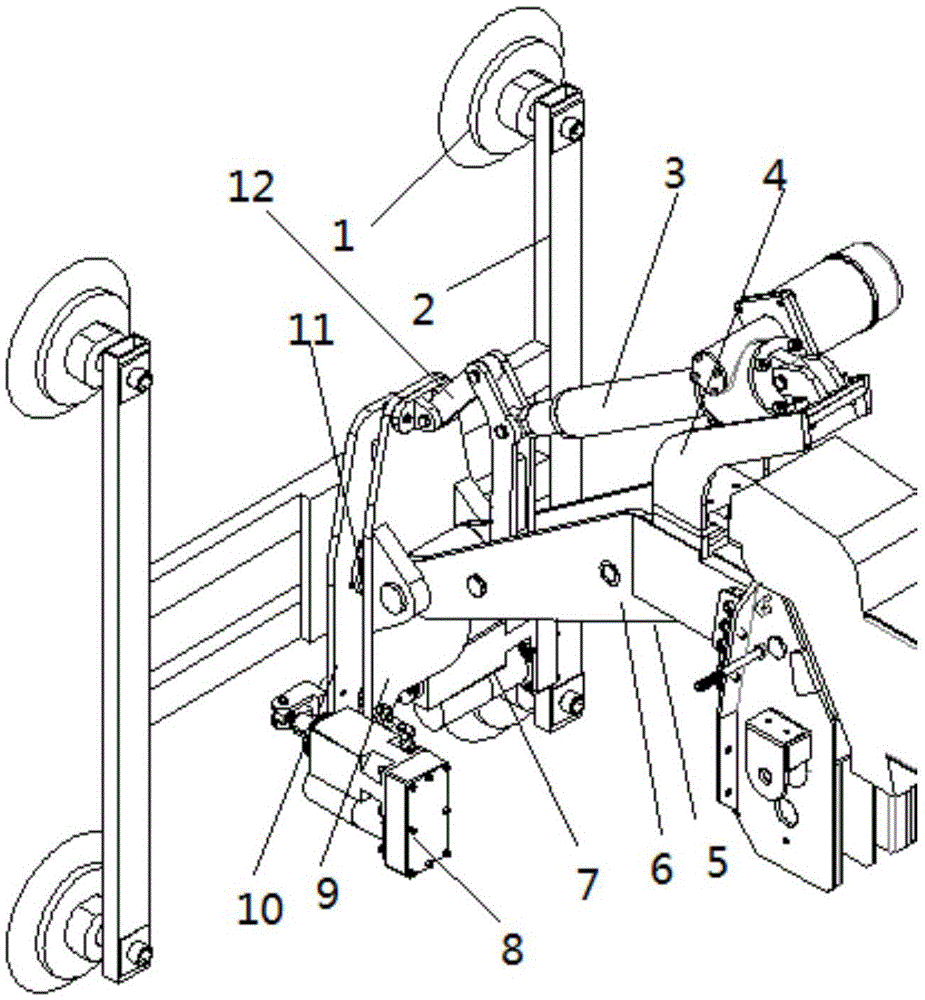

Three-degree-of-freedom high-altitude mounting manipulator for large plates

A technology with a degree of freedom and a manipulator, which is applied in the field of manipulators, can solve problems such as inability to install automatically, and achieve the effects of improving installation quality, compact structure, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The suction cup frame is an I-shaped structure composed of a beam and a longitudinal beam. The four vacuum suction cups are respectively located at the ends of the two longitudinal beams. The two ends of the beam are respectively connected to the middle of the two longitudinal beams. . The vacuum pump is a leak-proof vacuum pump.

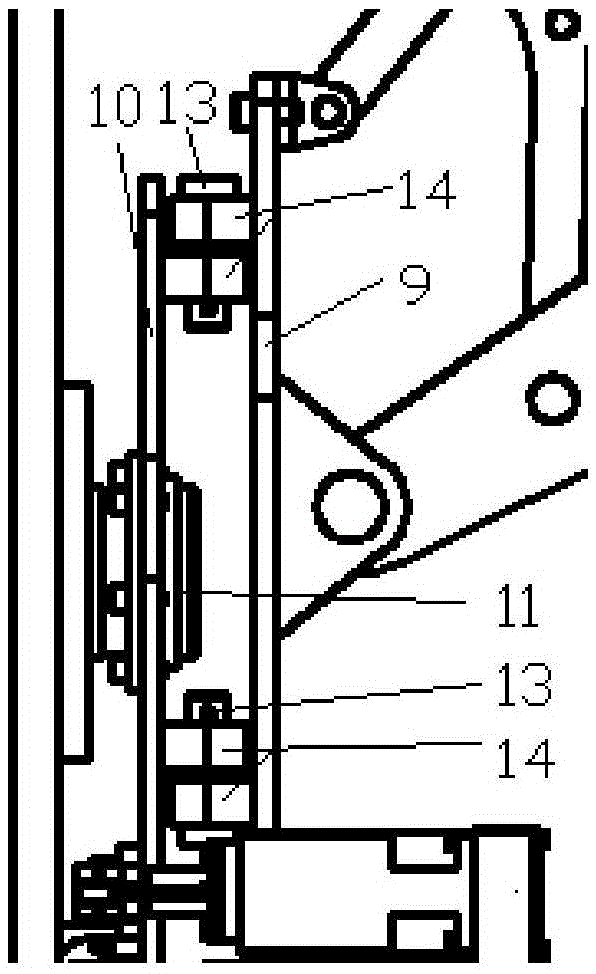

[0034] The pivot connection mechanism includes a pivot shaft rod and a shaft cylinder respectively fixed on the back of the swing support plate and the pivot mounting surface of the pitch support plate. The two ends of the pivot shaft rod respectively extend into different shaft cylinders. One end is fixed in the shaft cylinder, and the other end can rotate relative to the shaft cylinder. In order to make the structure of the pitch support plate and the swing support plate more compact, there are two sets of pivot connection mechanisms, which are respectively located above and below the end of the main shaft.

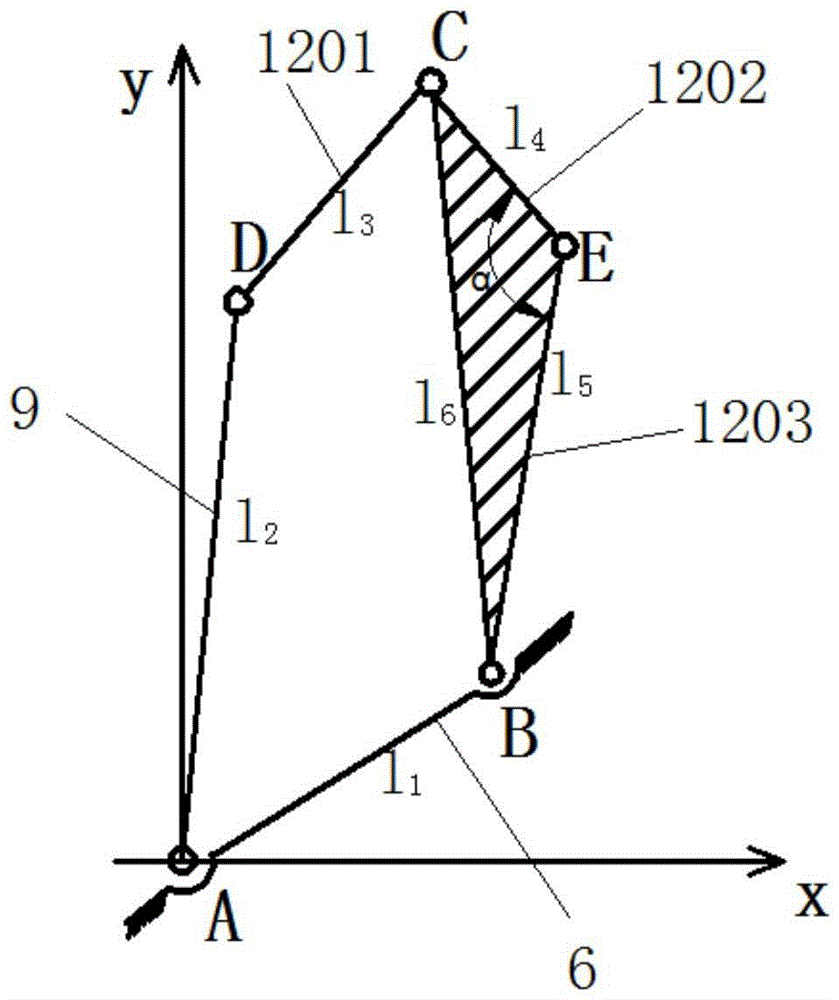

[0035] The parameters of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com