Connecting body of bumper and fender

A technology for bumpers and fenders, applied to bumpers, superstructures, superstructure subassemblies, etc., can solve problems such as unsatisfactory lightweight, easy oxidation and corrosion, troublesome installation and disassembly, etc., and achieve compact structure and beautiful appearance , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

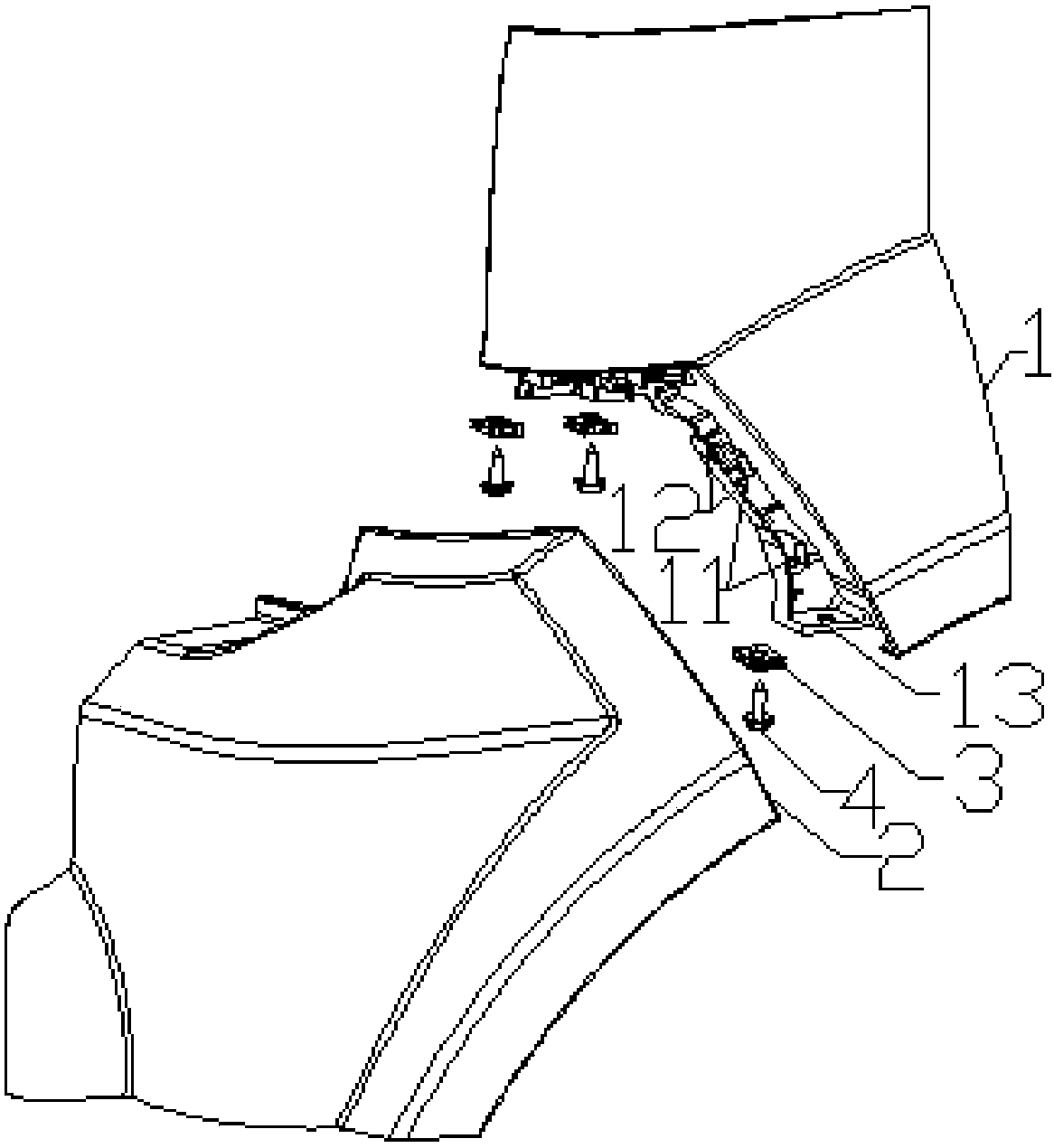

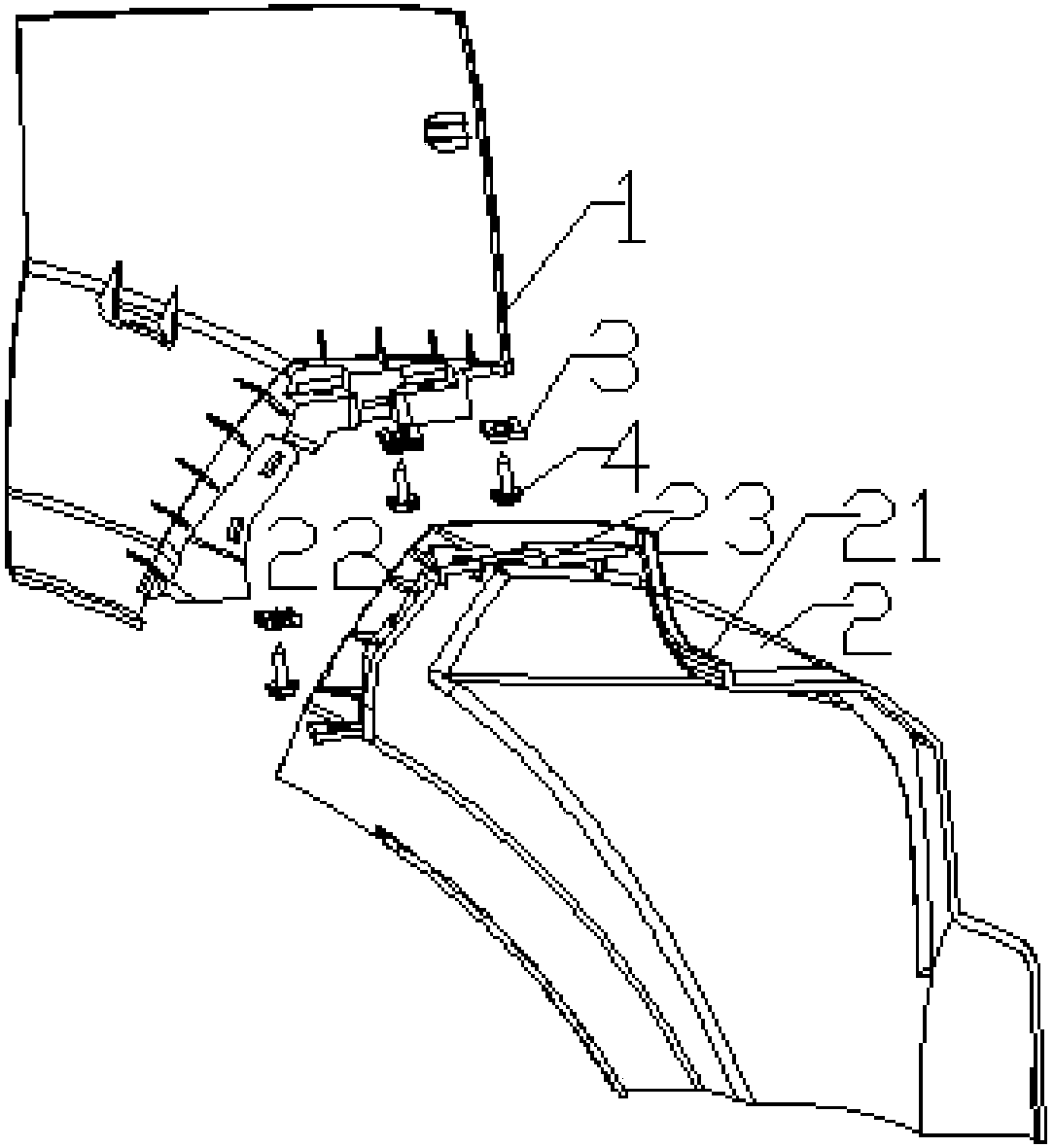

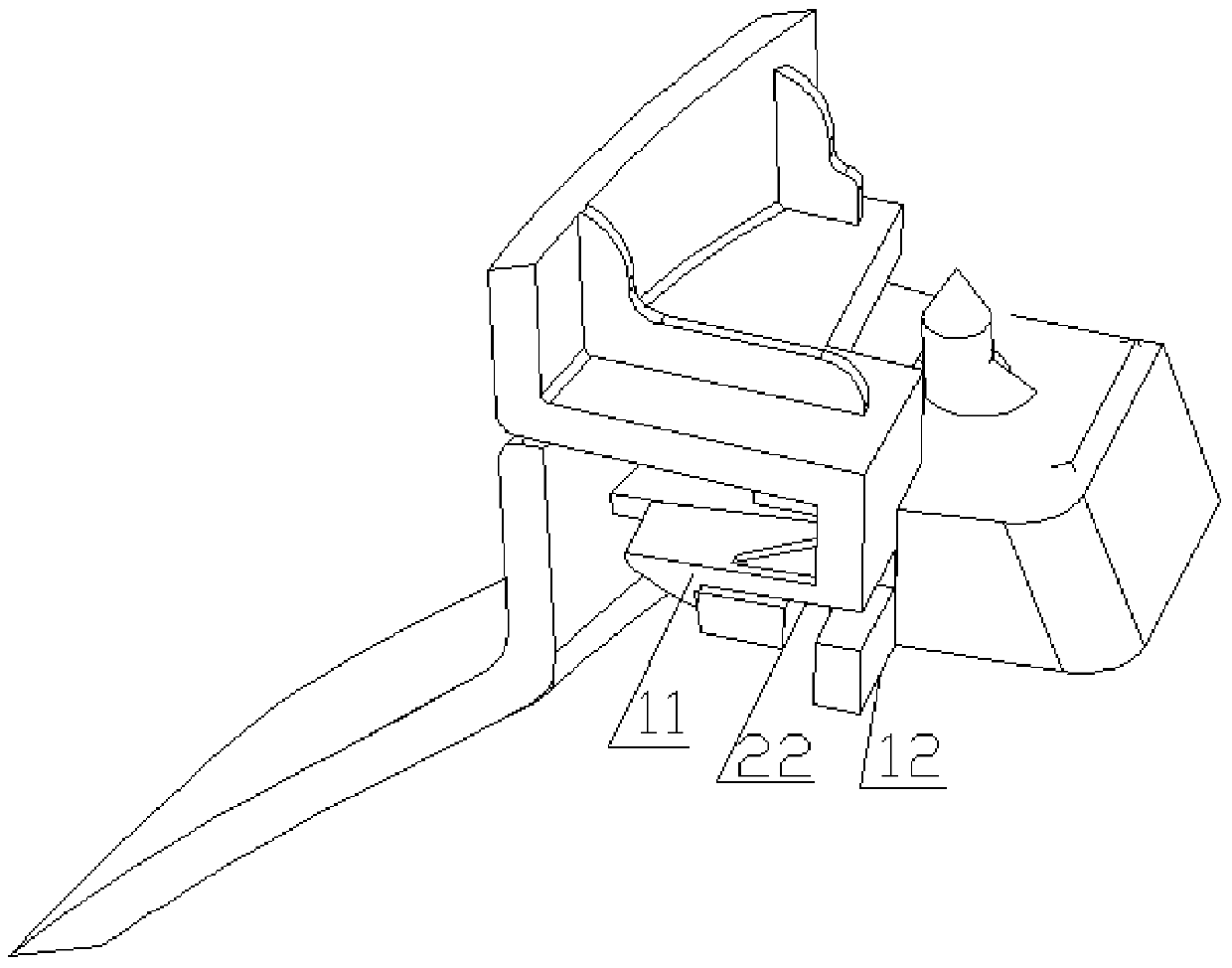

[0024] refer to figure 1 and figure 2 , the bumper and the fender connecting body of the present invention include: the bumper 2 and the fender 1, the connecting edges of the two are respectively designed into a snap-in shape that matches each other (to ensure the integrality of the connection between the two, and reduce the connection surface gap) and screw connection shape (to ensure the stability of the joint), wherein, the connection edge of the bumper 2 is provided with a card slot 21, a protrusion 22 and a screw hole substrate 23; the connection edge of the fender 1 A chuck 11 , a limiting block 12 (preferably an "L" shaped limiting block) and a screw hole substrate 13 are provided.

[0025] After the connecting edge of the bumper 2 and the fender 1 are matched and connected, the protruding head 22 of the bumper 2 and the limit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com