Ship cable tension stabilizer with self-adaptive capacity

An adaptive and stabilizer technology, applied in the direction of ships, etc., can solve the problems of complex and expensive control system, lag in motor response and action, and achieve the effect of avoiding cable failure, easy calculation, and avoiding shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

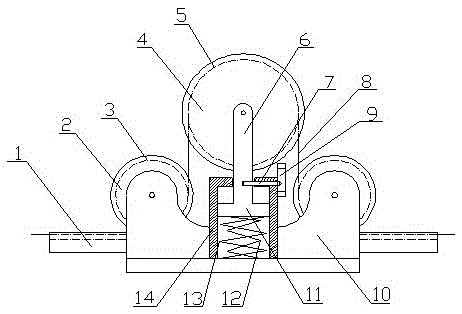

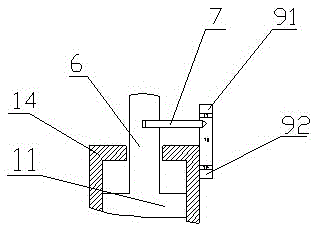

[0013] The electric windlass has a simple structure and is easy to control. It is gradually replacing the hydraulic windlass and improving the automatic control ability of the electric windlass. It is very important to control the tension of the cable. like figure 1 , figure 2 As shown, the present invention discloses a ship cable tension stabilizer with self-adaptive capability, comprising a base 10, a guide wheel 2 and a capstan mechanism; the base 10 is a horizontally arranged rectangular block, and the base 10 Both ends of the long axis direction are respectively provided with a guide guide wheel 2; the guide guide wheel 2 is installed on the machine base 10 through a quick loading and unloading pin, and has a wheel crown guide groove A3 for the cable 8 to go around in the circumferential direction; the two guide guide wheels The wheel crown guide groove A3 of the wheel 2 is located in the same plane, and there is a limit groove bar 1 below it to prevent the cable from s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com