Water-borne electronic remote control releaser

An electronic remote control and releaser technology, applied in ships, cargo handling equipment, passenger handling equipment, etc., can solve the signal transmission and reception that easily affects the wireless control system, cannot meet the needs of marine survey instruments or equipment, and has no solution to be released. It can solve problems such as object shaking or rotation, and achieve the effect of promoting the application value, releasing the action and time accurately, and ensuring the requirements of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

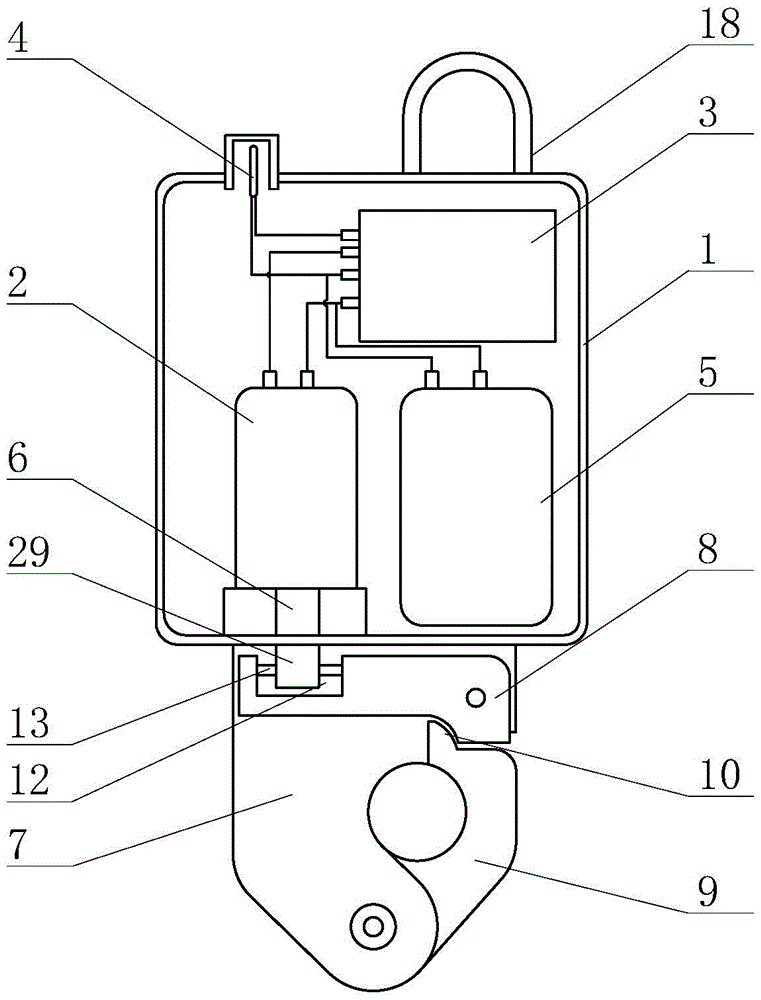

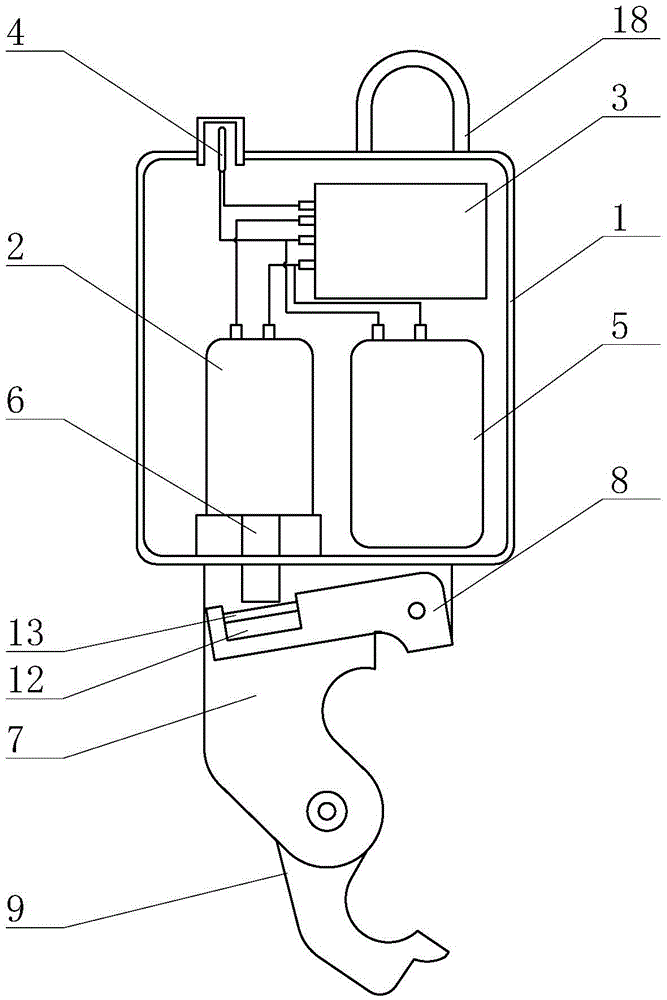

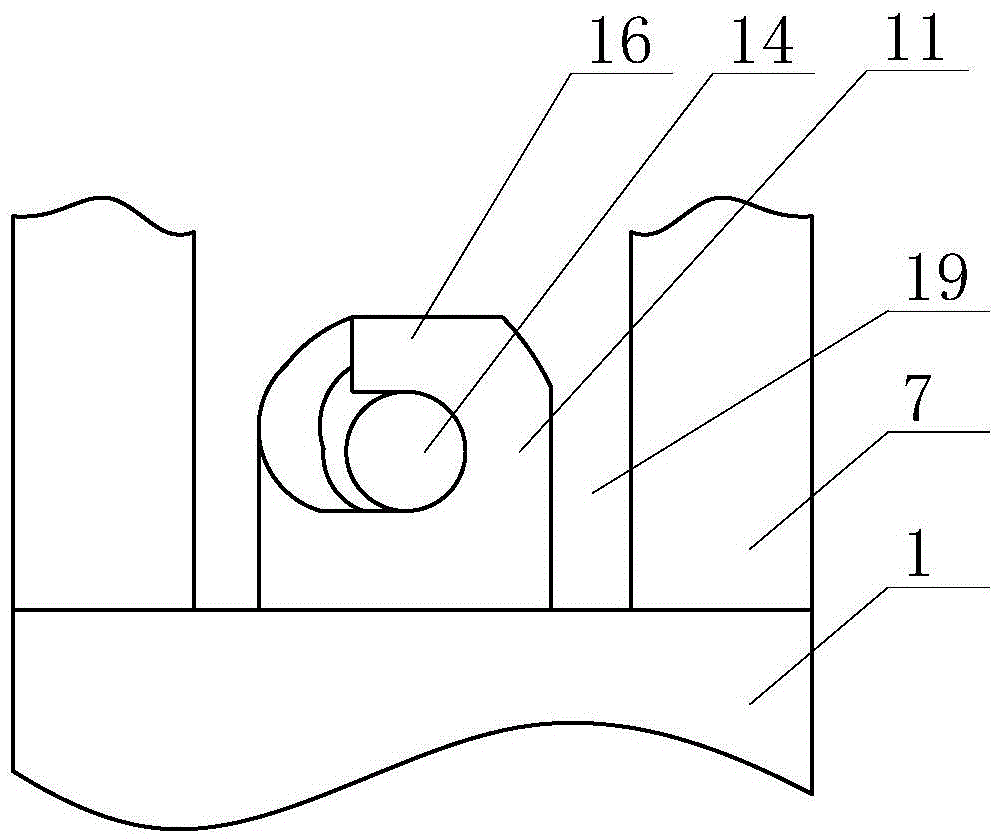

[0041] Such as Figure 1-6 As shown, the release action mechanism 29 in this embodiment includes a fixer 11 arranged at the lower end of the motor shaft 6, a groove 12 is set at the end of the movable block 8, and the fixer 11 extends into the groove 12; A horizontal connecting rod 13 is arranged in the groove 12, and the two ends of the connecting rod 13 are fixed with the movable block; The arc-shaped through groove 17 is opposite to and forms a channel 14 for accommodating the connecting rod. When the motor shaft 6 moves, the connecting rod 13 can be dropped from the locking tooth 17 or the connecting rod 13 and the locking tooth 17 can be fixed.

[0042] Release action mechanism 29 also can adopt following structure in addition: comprise the external thread that is arranged on motor shaft 6 lower ends, the end of movable block 8 is provided with the screw hole that cooperates with external thread, can promote movable block 8 ends when motor shaft 6 moves Move down around ...

Embodiment approach 2

[0046] Such as Figure 7-10 As shown, the difference between this embodiment and the first embodiment is that a rotating mechanism 30 is added between the suspension ring 18 and the first housing 1, and the upper and lower connection and installation are realized through the rotating mechanism 30. The rotating mechanism 30 includes a horizontal plate 20 1. The second housing 23 formed by the shell 21 and the ring end cover 22, the lower end of the suspension ring 18 is fixed to the horizontal plate 20; the vertical connecting shaft 24 is installed through the bearing in the second housing 23, and the connecting shaft 24 The lower end protrudes from the ring end cover 22 and is fixed with the first housing 1. The middle part of the connecting shaft 24 is provided with a radial arc groove 25, and an elastic member 26 is installed in the arc groove 25. The inner end of the elastic member 26 It is fixed with the connecting shaft 24, and a brake block 27 is installed on its outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com