Process method for using coal gas pressurization device for pressurizing coal gas

The technology of a pressurizing device and a process method is applied in the process field of using a gas pressurizing device to pressurize gas, which can solve the problems of poor pressurization effect, poor cooling effect, unsuitable gas flow, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

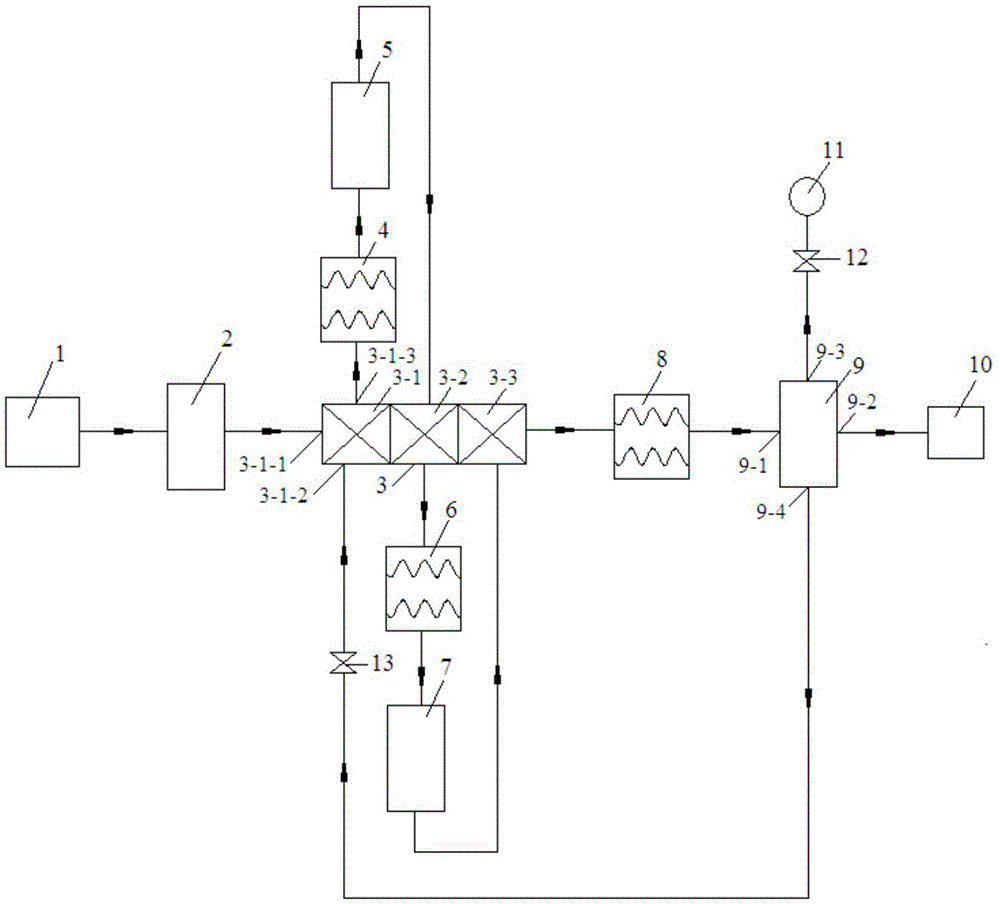

[0020] Specific embodiment one: present embodiment is a kind of process method that uses gas pressurization device to pressurize gas, is to finish according to the following steps:

[0021] The temperature in the water gas tank 1 is 40°C and the pressure is 150mmH 2 The water gas of O is passed into the first separator 2 to remove the liquid, and the water gas after the first separator 2 removes the liquid enters the first inlet port 3-1-1 of the first section of the gas pressurized compressor into the first section of the gas pressurized compressor Pressurize in 3-1, the pressure of water gas in the first stage 3-1 of the gas pressurizing compressor rises to 0.220MPa-0.230MPa, and the temperature rises to 122°C-124°C;

[0022] The water gas with a pressure of 0.220MPa-0.230MPa and a temperature of 122°C-124°C comes out of the first outlet port 3-1-3 of the first stage of the gas pressurized compressor and enters the first gas cooler 4. 4 to 38°C to 42°C, then enter the secon...

specific Embodiment approach 2

[0032]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the gas pressurization device is provided with an anti-surge circuit; 4 is drawn out, and flows back into the first section 3-1 of the gas pressurizing compressor through the regulating valve 13 and the second inlet port 3-1-2 of the first section of the gas pressurizing compressor to form an anti-surge circuit. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the gas pressurization device is provided with a vent pipe; the vent pipe is from the second outlet end of the fourth separator 9-3 lead, through the automatic switching valve 12 to vent to the torch 11. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com