A kind of method utilizing microorganism immobilization to prepare polyferric sulfate

A technology for polymerizing ferric sulfate and microorganisms, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of nitrogen oxides polluting the atmospheric environment, affecting the quality of treated water and drinking water, and prolonging the preparation cycle. The effect of reducing transportation costs, small footprint, and low economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

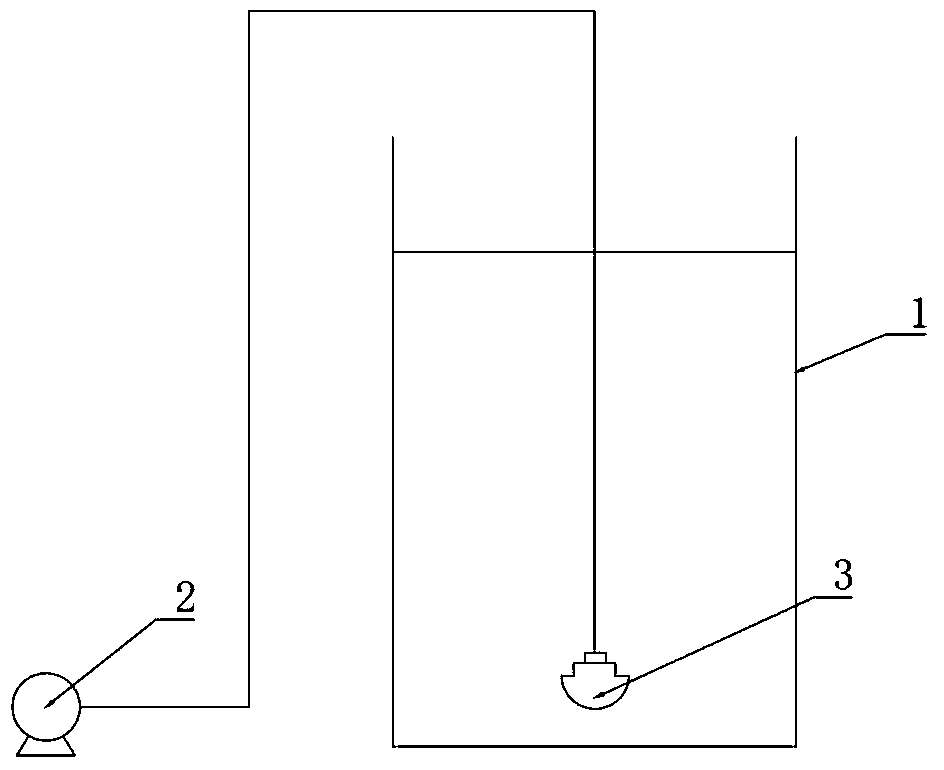

Image

Examples

Embodiment 1

[0031] Example 1 The total iron content is 40kg / m under the condition that the reaction solution ratio is 1:1 3 Preparation of PFS

[0032] A kind of method that utilizes immobilized microorganism catalytic oxidation ferrous sulfate of embodiment 1 to prepare biopolymeric ferric sulfate specifically comprises the following contents:

[0033] (1) Preparation of reaction feed liquid

[0034] According to the total iron content of the prepared PFS A 40kg / m 3 , according to the formula: X=40×V×278 / 56 ,when V= When 10L, calculate the industrial FeSO that needs to be added 4 ·7H 2 O's mass X Be 2Kg, obtain reaction material liquid , the total iron content of the A Refers to the amount of ferrous iron and ferric iron contained in each cubic meter of volume, V is the volume;

[0035] (2) Preparation of polyferric sulfate stock solution

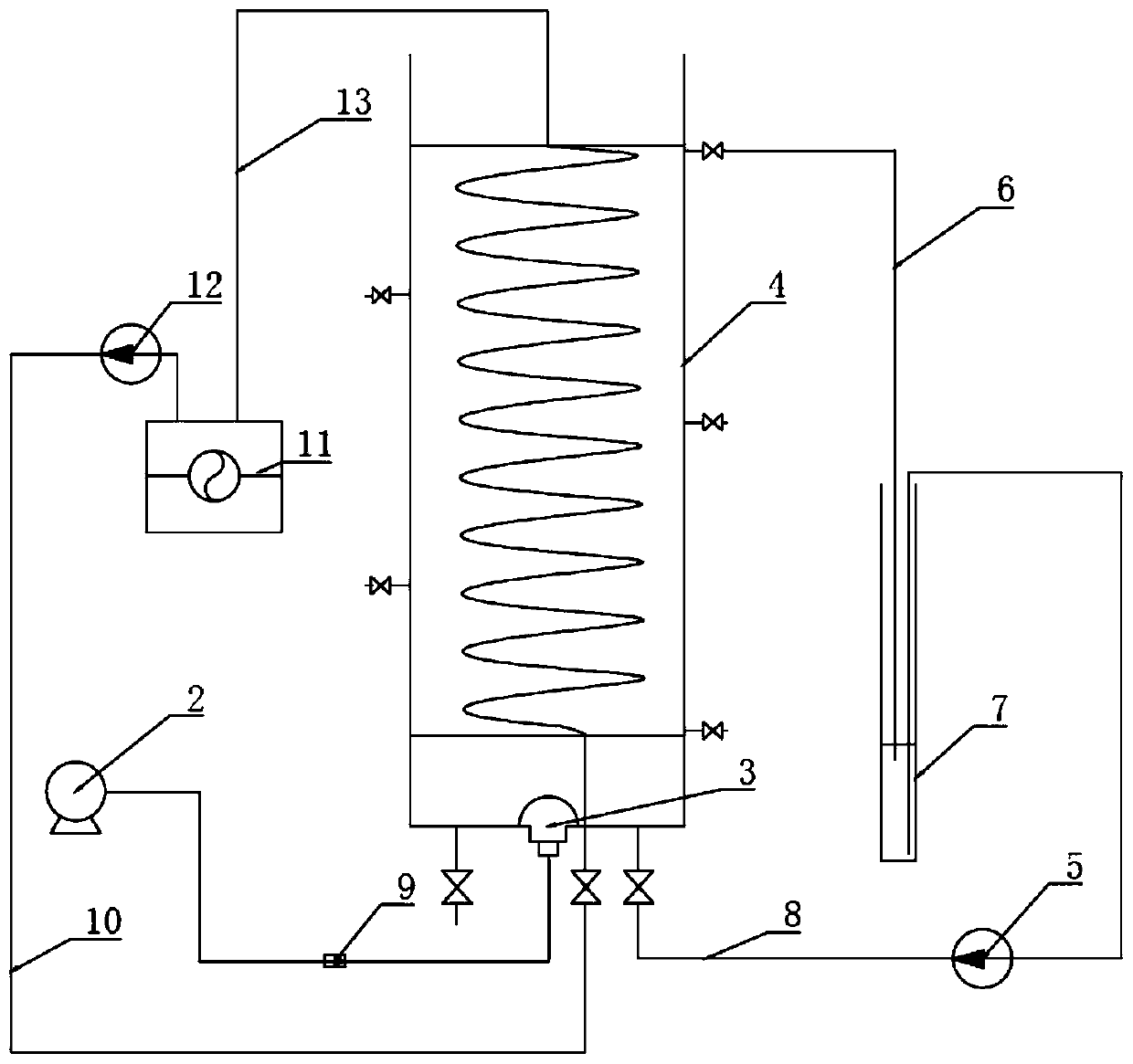

[0036] Such as figure 2 As shown, take m The reaction feed liquid in the above step (1) of L , after introducing microorganisms, i...

Embodiment 2

[0039] Example 2 The total iron content is 40kg / m under the condition that the reaction solution ratio is 0:4 3 Preparation of PFS

[0040] A kind of method that utilizes immobilized microorganism catalytic oxidation ferrous sulfate of embodiment 2 to prepare biopolymeric ferric sulfate specifically comprises the following contents:

[0041] (1) Preparation of reaction feed liquid

[0042] According to the total iron content of the prepared PFS A 40kg / m 3 , according to the formula: X=40×V×278 / 56 ,when V =10L, calculate the industrial FeSO that needs to be added 4 ·7H 2 O's mass X Be 2Kg, obtain reaction material liquid ;

[0043] (2) The total iron content is 40kg / m 3 Preparation of Polyferric Sulfate

[0044] Such as figure 2 As shown, take V 0 The reaction feed liquid of L above-mentioned step (1) , do not add polyferric sulfate stock solution, the ratio is P =0:4, after the microorganisms are introduced, they are circulated in the bioreactor, and air is...

Embodiment 3

[0046] Example 3 The total iron content is 40kg / m under the condition that the ratio of the reaction solution is 1:2 3 Preparation of PFS

[0047] A kind of method that utilizes immobilized microorganism catalytic oxidation ferrous sulfate of embodiment 3 to prepare biopolymeric ferric sulfate specifically comprises the following contents:

[0048] (1) Preparation of reaction feed liquid

[0049] According to the total iron content of the prepared PFS A 40kg / m 3 , according to the formula: X=40×V×278 / 56 ,when V =10L, calculate the industrial FeSO that needs to be added 4 ·7H 2 O's mass X Be 2Kg, obtain reaction material liquid ;

[0050] (2) Preparation of polyferric sulfate stock solution

[0051] Such as figure 2 As shown, take m The reaction feed liquid in the above step (1) of L , after introducing microorganisms, it is circulated in the reactor, and air is introduced at a room temperature of 25-28°C for aeration. The aeration rate is 1.08-1.81L / L min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com