Dry powder plaster

A technology of clay and dry powder, which is applied in the field of building materials, can solve the problems of heat preservation, fire prevention, poor acid and corrosion resistance, etc., and achieve high fire resistance, acid and corrosion resistance, broad market prospects, and good acid and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A kind of dry powder cement, the main components are phosphorus slag, boiler slag, waste clinker and gypsum produced in the production of calcium aluminate powder and mixed in proportion, and after mixing, use a ball mill to grind it into ultrafine powder. The components are composed as follows in percentages and parts : Phosphorus slag 30%, boiler slag 25%, waste clinker produced in the production of calcium aluminate powder 40%, gypsum 5%.

Embodiment 2

[0013] A kind of dry powder cement, the main components are phosphorus slag, boiler slag, waste clinker and gypsum produced in the production of calcium aluminate powder and mixed in proportion, after mixing, use a ball mill to grind into ultrafine powder: phosphorus slag 35%, boiler slag 29% %, 35% of waste clinker produced in the production of calcium aluminate powder, and 1% of gypsum.

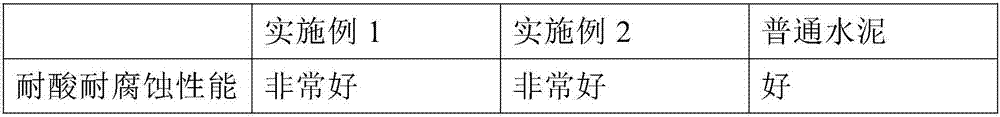

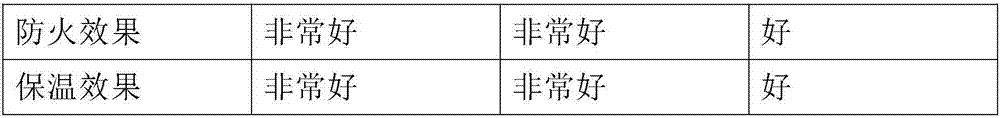

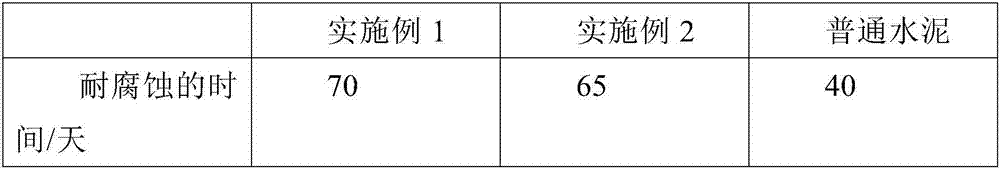

[0014] Known by embodiment 1 and embodiment 2, above-mentioned embodiment 1 and embodiment 2 are used to paint on the exterior wall, and it and ordinary cement are painted on the exterior wall to get table 1,

[0015] Table 1 Example 1, Example 2 and common cement are used in the contrast effect of external wall painting under the same environment and conditions

[0016]

[0017]

[0018] As can be seen from Table 1, when the dry powder mortar of the present invention is used on the outer wall, it has better acid and corrosion resistance than ordinary cement, good fire prevention effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com