Engine cooling system with sand strap and control method thereof

A technology of engine cooling and grit chamber, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of high energy consumption, cumbersome disassembly and maintenance, etc., and achieve low energy consumption, simple disassembly and maintenance, and easy The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

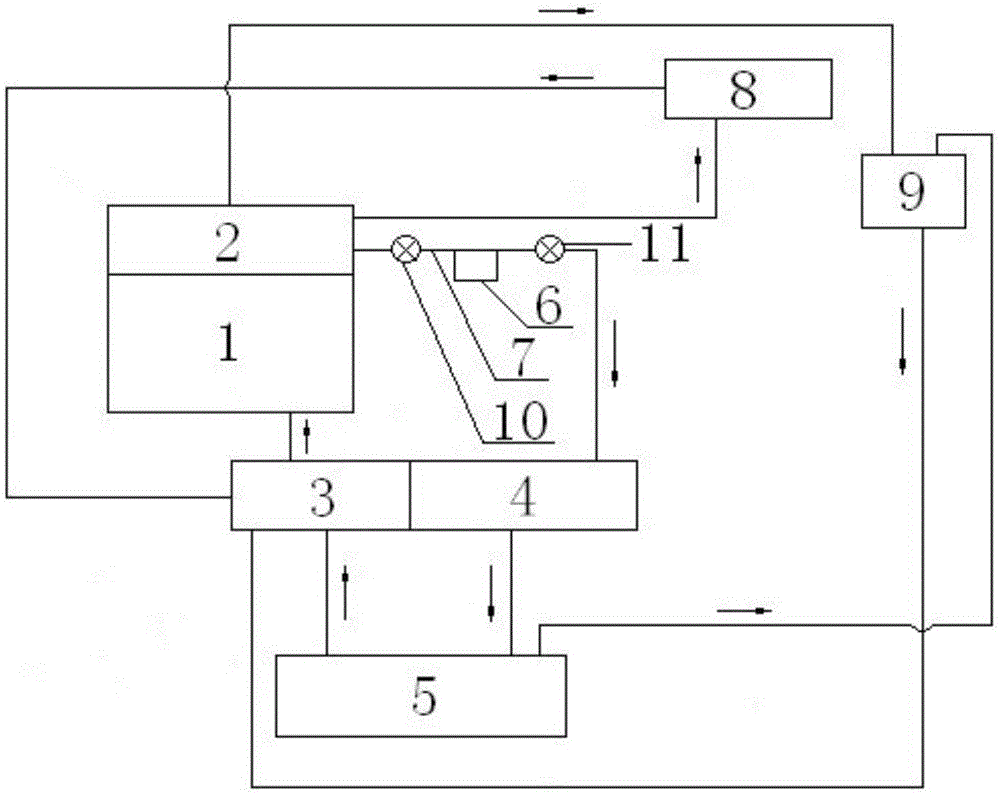

[0047] see figure 1 , an engine cooling system with a grit chamber, including a cylinder water jacket 1, a cylinder head water jacket 2, a water pump 3, the cylinder body water jacket 1 is connected with the cylinder head water jacket 2, and the water outlet of the cylinder head water jacket 2 The water inlet of the radiator 5 is connected through the thermostat 4, and the water outlet of the radiator 5 is connected with the water jacket 1 of the cylinder body through the water pump 3. A grit chamber 6 is arranged on the pipeline 7 between them, and the upper end of the grit chamber 6 communicates with the pipeline 7.

[0048] According to the above scheme, a control method of an engine cooling system with a grit chamber, the control method includes the following steps: the coolant in the water pump 3 passes through the cylinder water jacket 1, the cylinder head water jacket 2, the pipeline 7, the The thermostat 4 and the radiator 5 flow back into the water pump 3; when the c...

Embodiment 2

[0050] Basic content is the same as embodiment 1, the difference is:

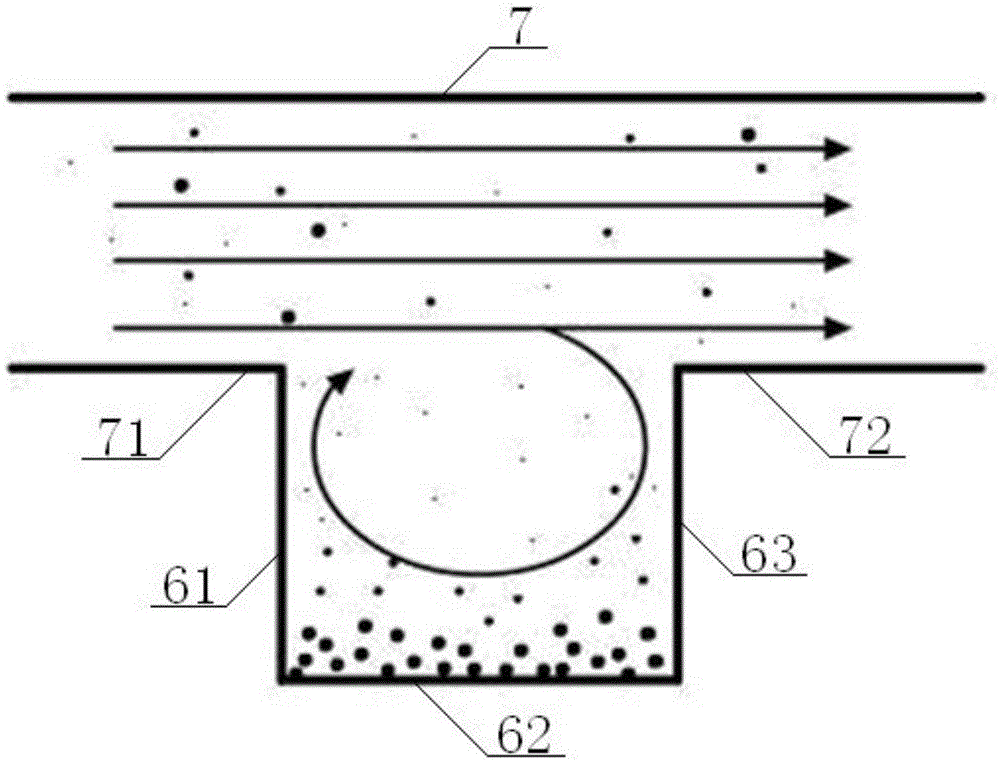

[0051] see figure 2 , image 3 , the grit chamber 6 is a rectangular structure, the grit chamber 6 includes a No. 1 tank side 61, a tank bottom side 62, and a No. 2 tank side 63, and the upper end of the No. 1 tank side 61 is vertically connected with the left lower wall 71 of the pipeline 7, The lower end of the first groove edge 61 is vertically connected with the left end of the groove bottom edge 62, the right end of the groove bottom edge 62 is vertically connected with the lower end of the second groove edge 63, and the upper end of the second groove edge 63 is perpendicular to the lower right wall 72 of the pipeline 7 connection; the outside of the grit chamber 6 is provided with a grit box 64, the No. 1 tank side 61, the tank bottom side 62, and the No. 2 tank side 63 are all located inside the grit box 64, and the No. 1 tank side 61 and the No. 2 tank side The groove edge 63, the left side of th...

Embodiment 3

[0054] Basic content is the same as embodiment 1, the difference is:

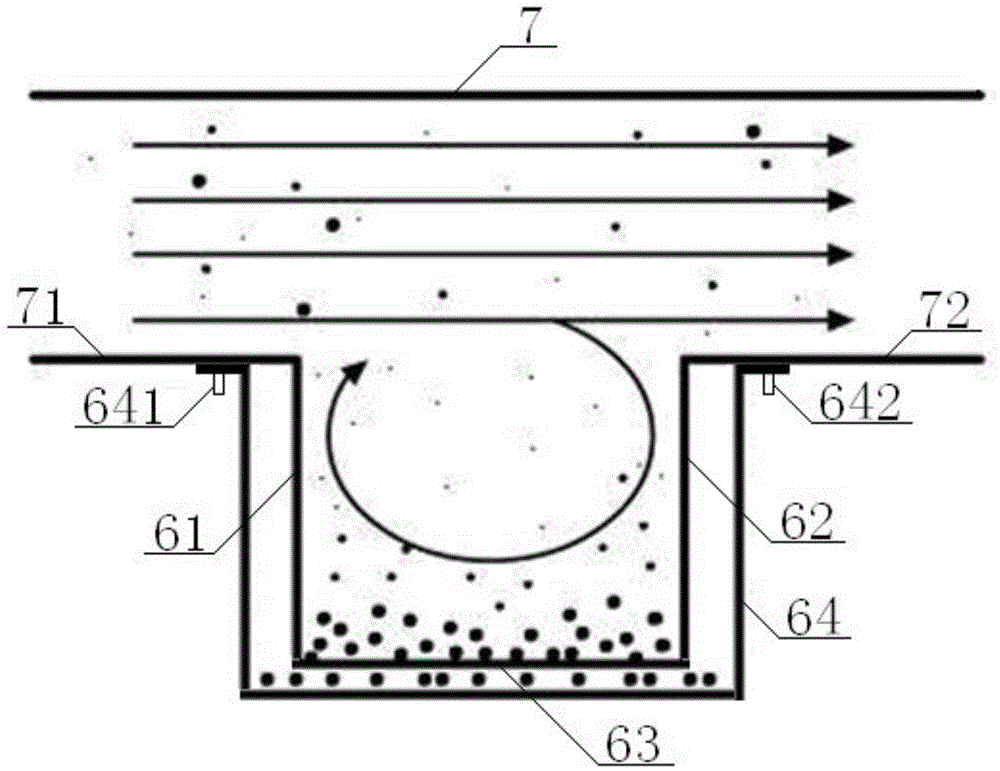

[0055] see Figure 4 , the outside of the grit chamber 6 is provided with a grit box 64, the upper left end of the grit box 64 is connected with the lower left wall 71 of the pipeline 7 through the No. 1 bolt 641, and the upper right end of the grit box 64 is connected with the No. 2 bolt 642 Connected with the lower right wall 72 of the pipeline 7, the grit chamber 6 includes a No. 1 tank side 61 and a No. 2 tank side 63. The No. 1 tank side 61 and the No. 2 tank side 63 are all located inside the grit chamber 64. The upper end of the No. 1 tank side 61 is vertically connected to the left lower wall 71, the upper end of the No. 2 tank side 63 is vertically connected to the right lower wall 72, and the lower ends of the No. 1 tank side 61 and the No. 2 tank side 63 are located above the bottom of the grit chamber 6 , No. 1 groove side 61, No. 2 groove side 63, the left side of the grit chamber 64, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com