Marine diesel turning mechanism

A marine diesel engine and cranking mechanism technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of unacceptable marine engines, low cranking efficiency, lack of interlocking function of diesel engine starting system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

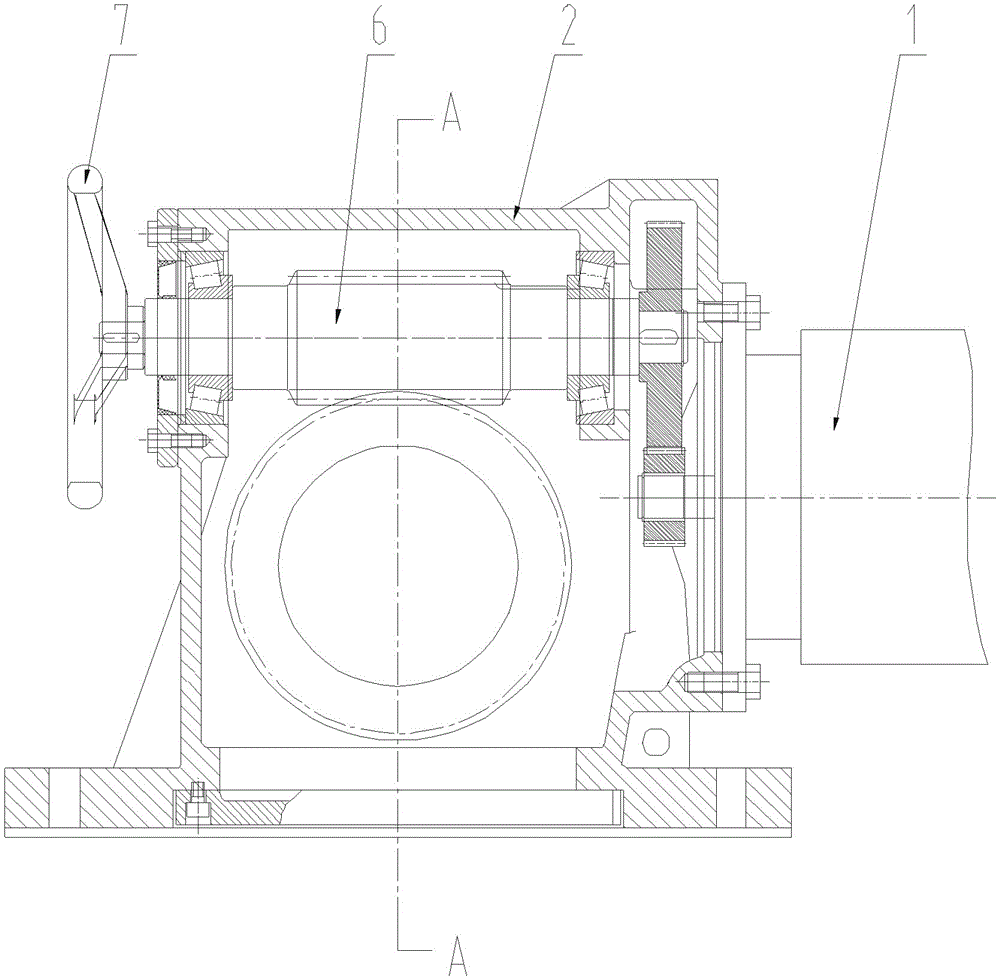

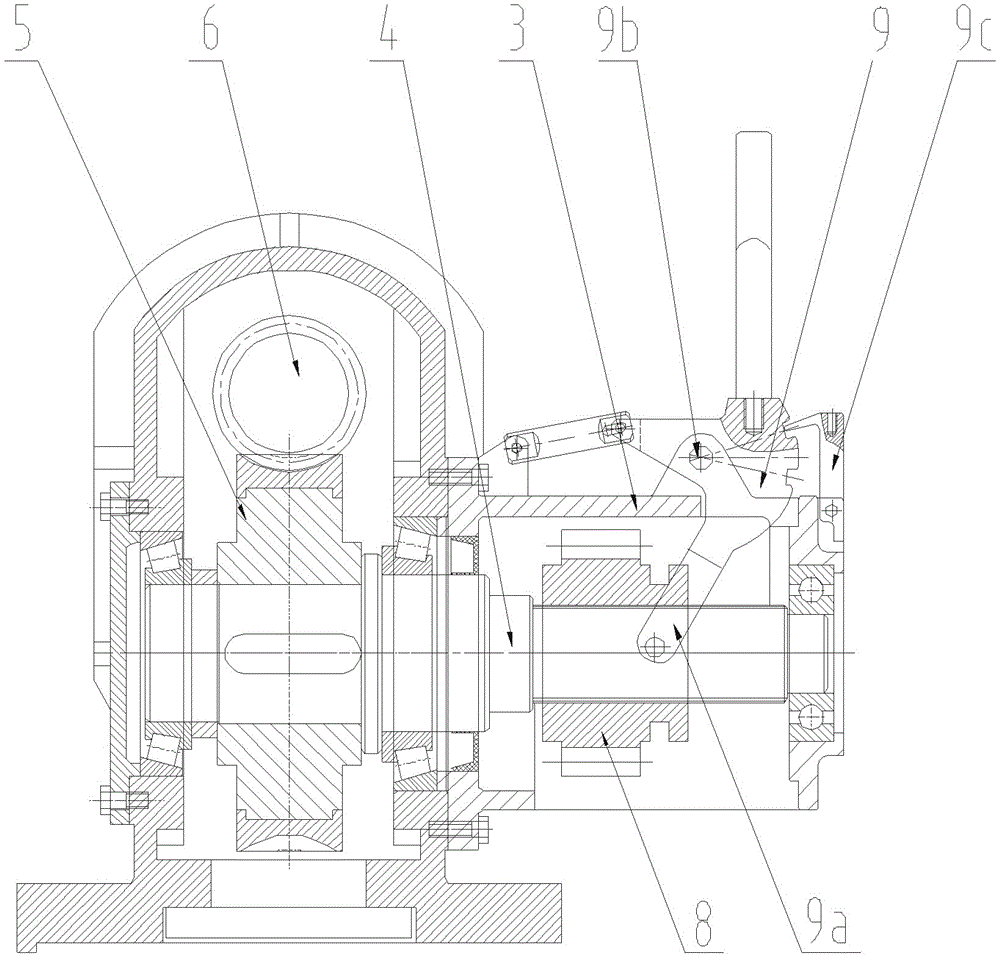

[0016] Such as figure 1 , 2 The cranking mechanism of a marine diesel engine shown includes a motor 1, a casing 2, an output flange 3, and an output shaft 4 installed in the casing 2, a worm wheel 5 and a worm 6, and the output shaft 4 and the worm 6 are All adopt tapered roller bearings to install on the box body 2; one end of the worm 6 and the output shaft of the motor are driven through a gear, and the other end of the worm 6 is equipped with a hand wheel 7; the worm wheel 5 is installed on the output shaft through a flat key. On the shaft 4, the output end of the output shaft 4 passes through the box body 2 and is installed in the output flange 3, the output end of the output shaft 4 is sleeved with a sliding gear 8; the output flange 3 is equipped with A shift fork assembly 9, the shift fork assembly 9 includes a fork arm 9a, a sensing device 9b and a positioning device 9c, the fork arm 9a can push the sliding gear 8 to move axially on the output shaft 4, the sensing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com