Shrink Tube Synthetic Jet Valveless Piezo Pump

A valveless piezoelectric pump and synthetic jet technology, applied to parts, pumps, pump elements, etc. of pumping devices for elastic fluids, to achieve the effects of low energy consumption, large vibration frequency range, and high flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

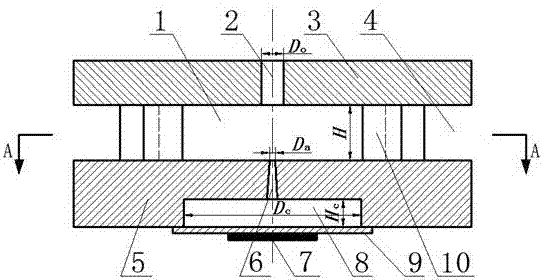

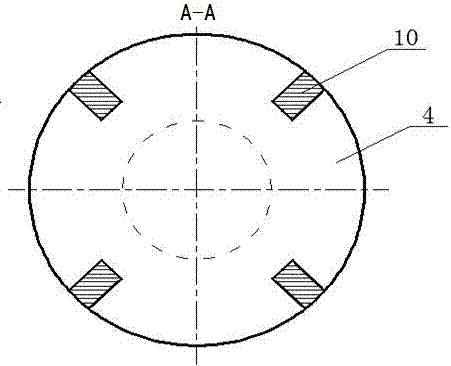

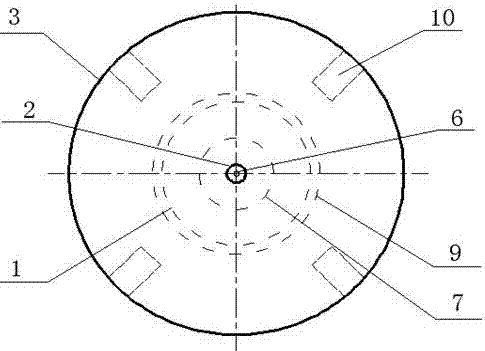

[0016] see figure 1 , figure 2 with image 3 , the present invention includes an upper pump body 3 and a lower pump body 5, the upper pump body 3 is located directly above the lower pump body 5, and the central axes of the two are collinear. Connect the upper pump body 3 and the lower pump body 5 with four columns 10, the upper ends of the columns 10 are fixed on the outer edge of the upper pump body 3, and the upper ends of the columns 10 are fixed on the outer edges of the lower pump body 5. . The four upright columns 10 are evenly arranged along the circumferential direction, and the angle between the centers of every two upright columns 10 is 90 degrees. The gaps between the four columns 10 form the pump inlet 4, which is a circumferential inlet. The space surrounded by four columns 10 , the upper pump body 3 and the lower pump body 5 is the upper chamber 1 . The surrounding fluid enters the upper chamber 1 from the gap pump inlet 4 between the columns 10 .

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com