Differential device and method of manufacturing the same

A technology of a differential device and a manufacturing method, which are applied in the directions of differential transmissions, transmissions, belts/chains/gears, etc., to achieve the effect of preventing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to preferred embodiments of the present invention shown in the accompanying drawings.

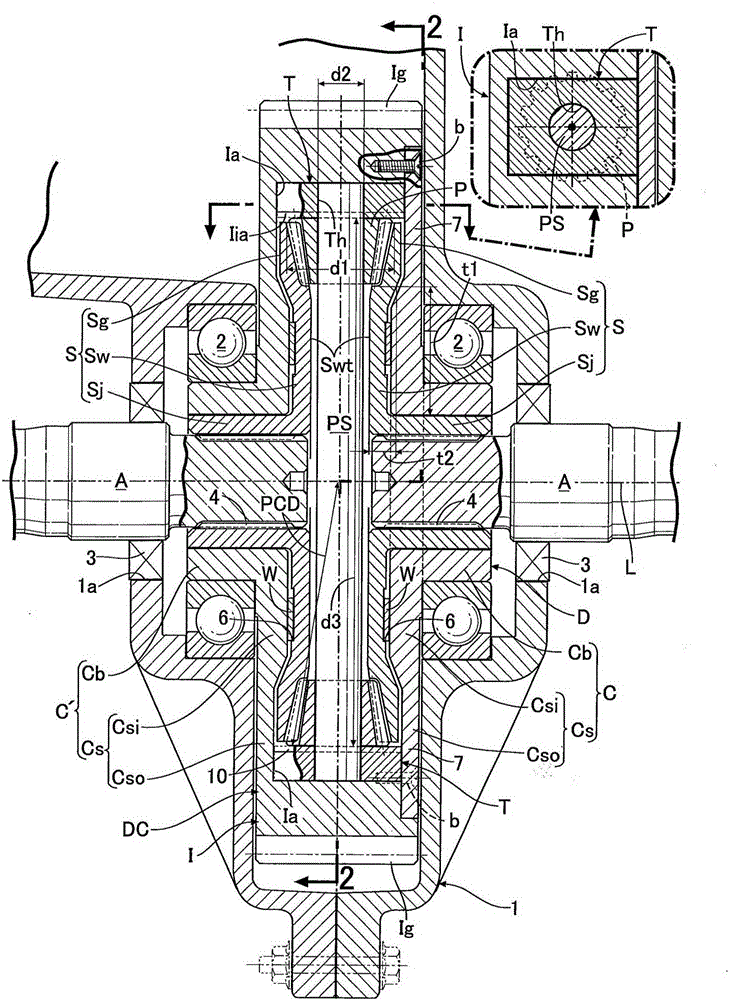

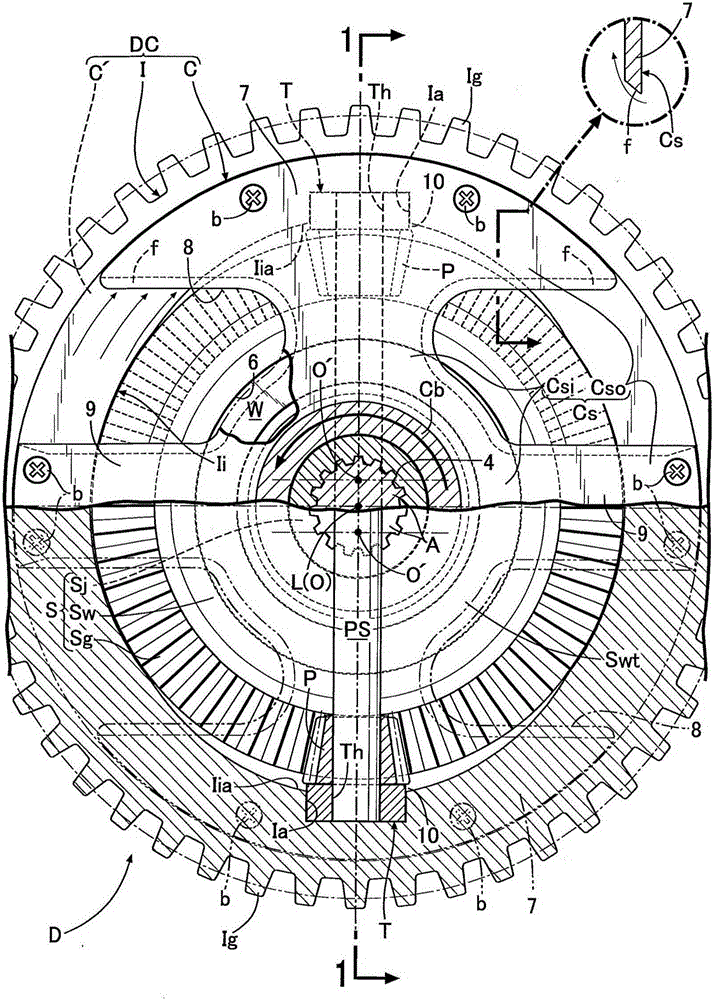

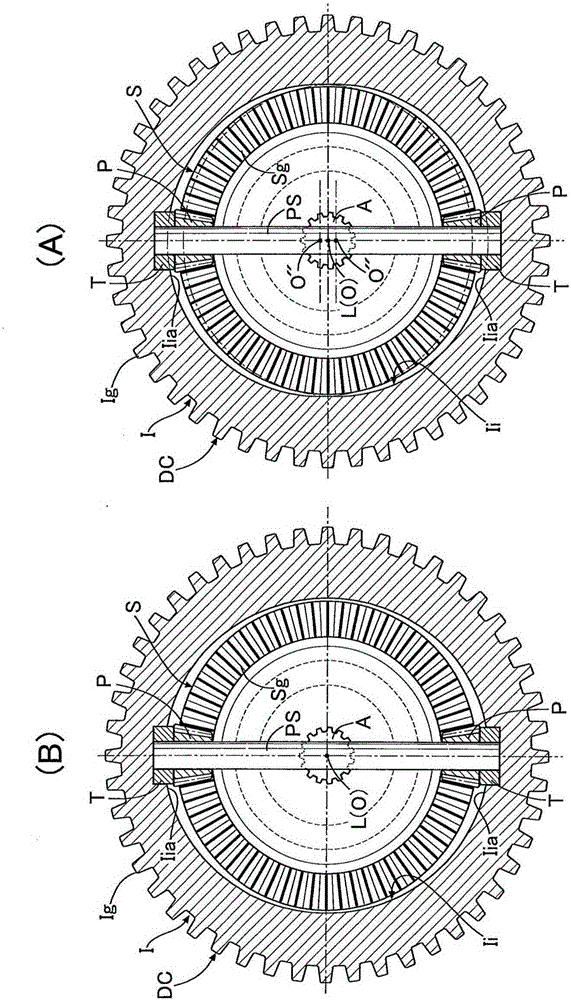

[0027] First, in figure 1 and figure 2 Among them, the differential device D is used to distribute and transmit the rotational drive force transmitted from the engine (not shown) mounted on the automobile to the left and right pair of output shafts A connected to the left and right pair of axles, thereby allowing the left and right The left and right axles are driven while differentially rotating the axles, and the differential device D is housed and supported in, for example, a transmission 1 fixed to the center of the rear part of the vehicle body.

[0028] This differential device D has: a plurality of pinion gears P; pinion gear shaft PS, which is a pinion gear supporting portion that supports these pinion gears P in a rotatable manner; The gear shaft PS supports the pinion shaft PS so as to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com