Combined digital valve with independent control of load port and its method

An independent control and combined technology, applied in the direction of multi-way valves, valve devices, servo motor components, etc., can solve the problems of low flow resolution, high flow output accuracy requirements, and inability to meet flow resolution, etc., to achieve control and Improved energy saving performance, improved control performance, and increased control freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

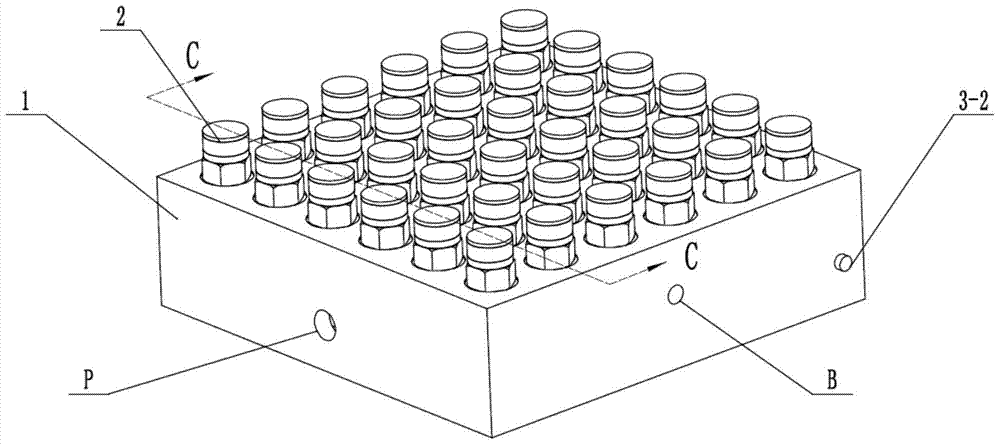

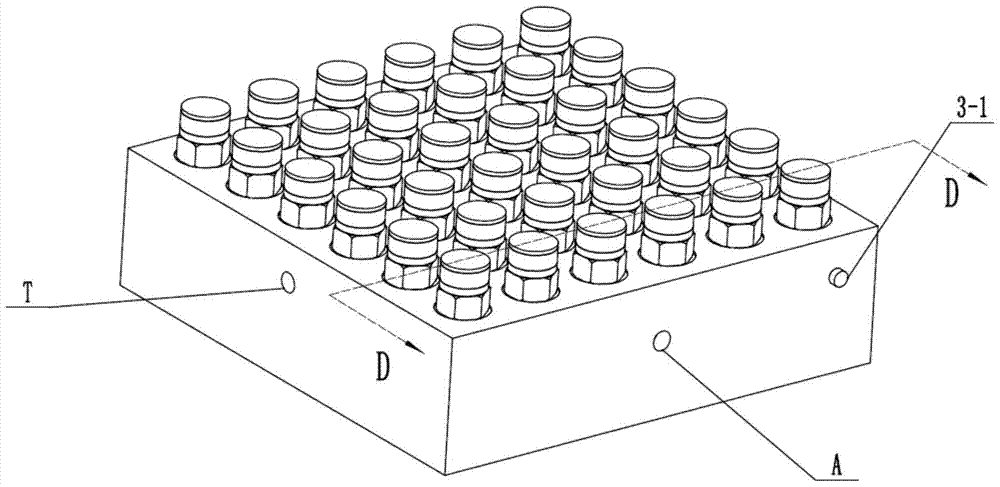

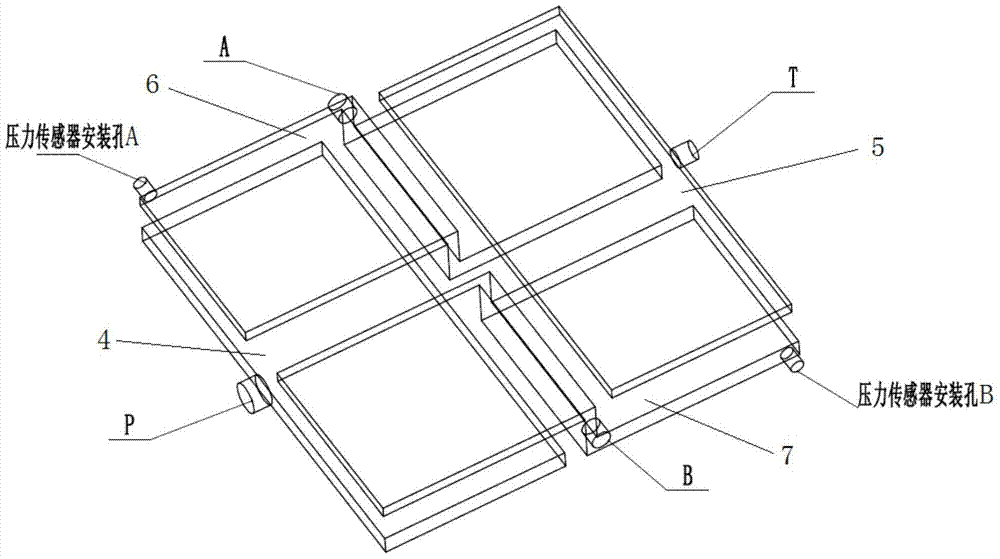

[0037] Such as Figure 1-8 As shown, the combined digital valve independently controlled by the load port includes a valve block 1, a plurality of on-off valves 2, a load port pressure sensor A3-1, and a load port pressure sensor B3-2. On the valve block 1; there is a threaded hole on each of the four sides of the valve block 1, wherein the threaded hole P and the threaded hole T are arranged oppositely, and the threaded hole A and the threaded hole B are arranged oppositely, and the switch valve 2 is divided into four groups of switch valves group, the number of switch valves in each switch valve group is k*k, and the switch valves 2 are evenly arranged on the valve block 1 in a square shape, k is a natural number,

[0038] There are four oil passages in the valve block 1, and the four oil passages are respectively connected with 4 threaded holes, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com