A high-precision ultra-high pressure liquid phase simulation load accumulation error test platform

A technology of ultra-high pressure liquid phase and cumulative error, which is applied in the field of liquid chromatography analysis, can solve problems such as screw pitch cumulative error, flow accuracy, and accuracy system delay volume are difficult to meet requirements, restricting the development of UHPLC, etc., to reduce force Effects of wave motion, improved accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

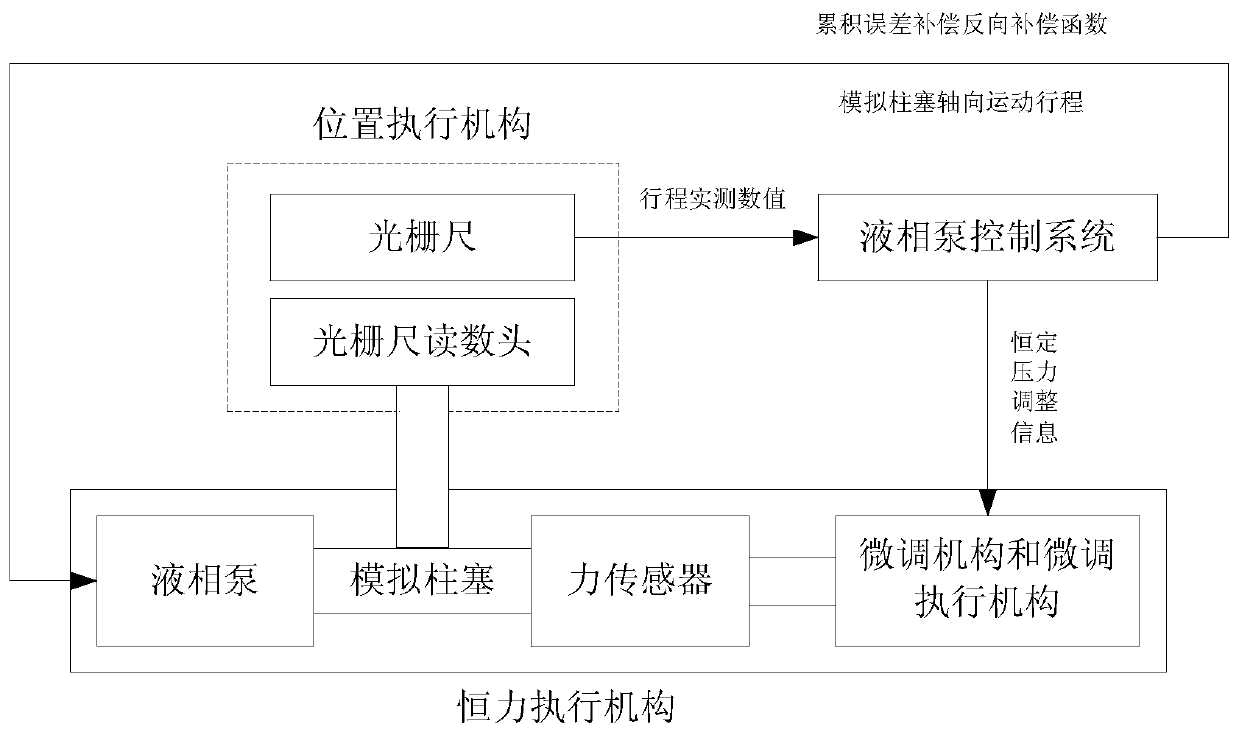

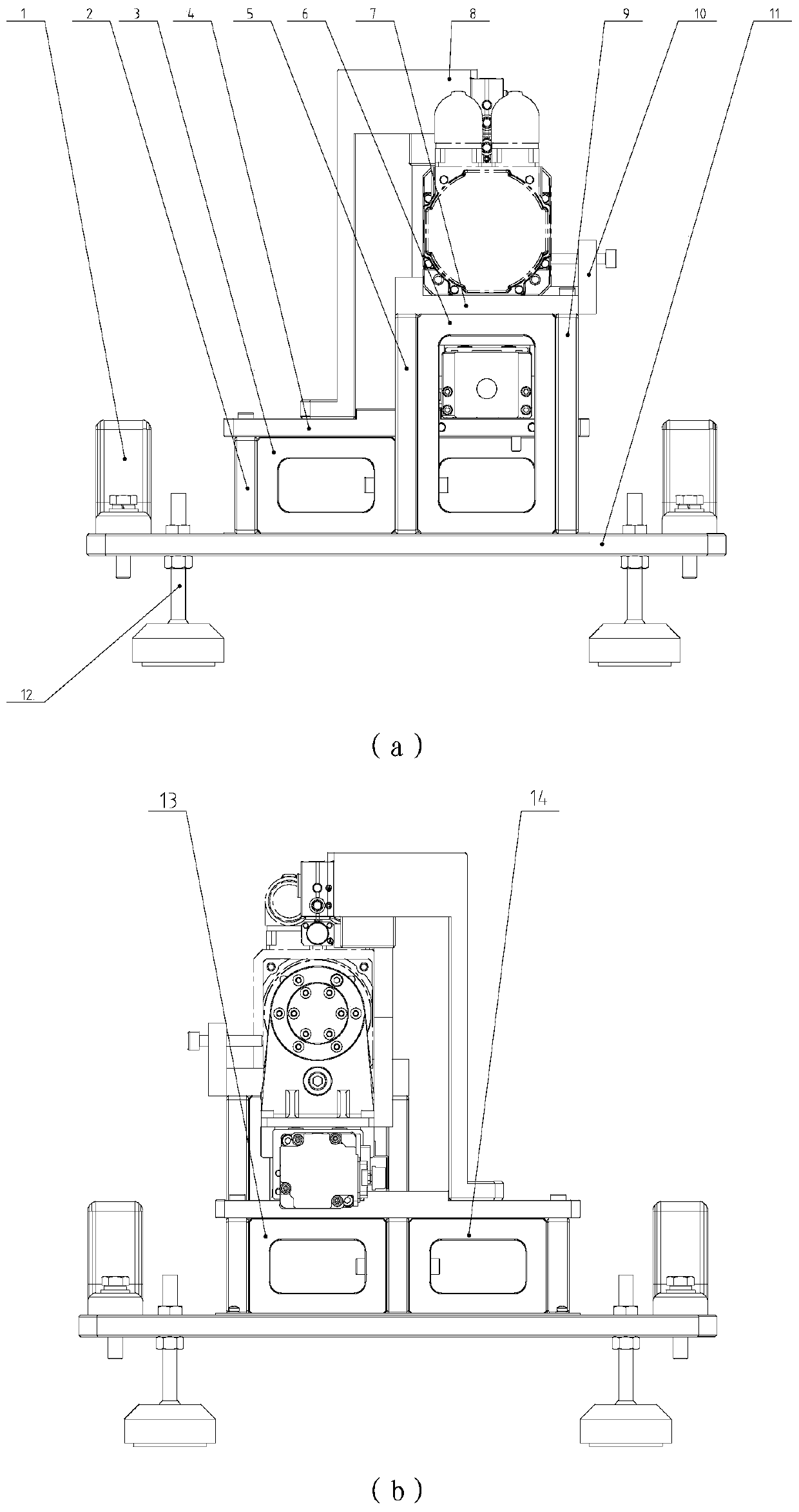

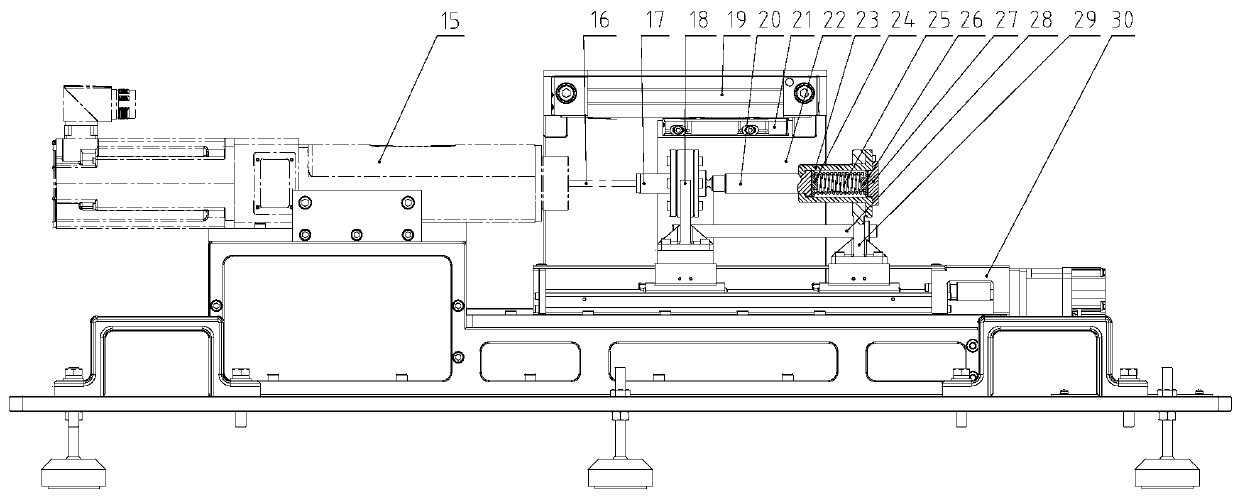

[0020] Such as figure 1 As shown, a high-precision ultra-high pressure liquid phase simulated load accumulation error test platform is divided into three parts: the test bench, the constant force actuator and the position feedback mechanism. The simulated load accumulation is realized through the coordination and cooperation of the constant force actuator and the position feedback mechanism. Error detection, reverse compensation and elimination are performed through the liquid phase pump control system, and the two mechanisms are fixed by the test bench. The constant force actuator is driven by a high-precision ultra-high pressure liquid phase pump to move the simulated plunger along the axial direction. The simulated plunger 16 cooperates with the force sensor 17 to detect the pressure on the simulated plunger 16 through the force sensor 17. In order to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com