Speed reduction mechanism

A technology of a reduction mechanism and a base, applied in the aerospace field, can solve the problems of poor transmission effect, poor connection structure stability, low integration, etc., and achieve the effects of stable and fast power transmission, stable connection structure, and high-precision output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

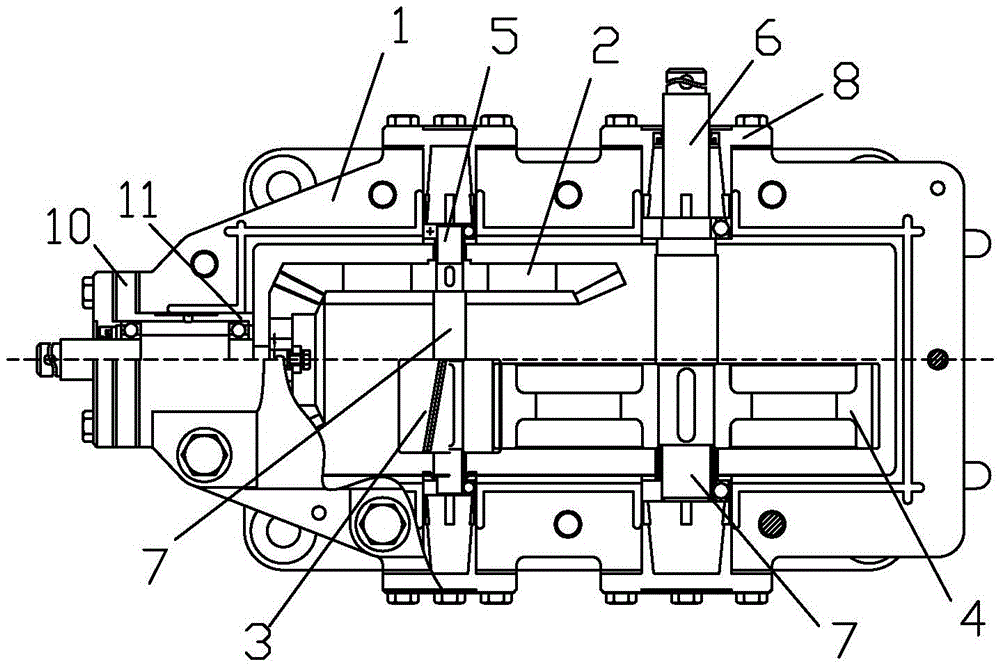

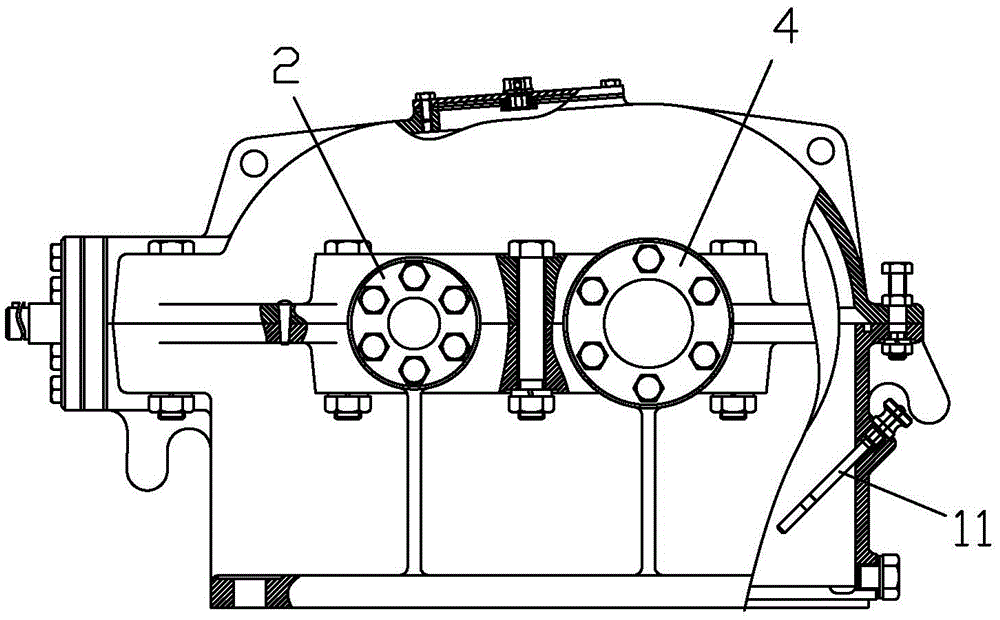

[0019] A deceleration mechanism, comprising a base 1, a gear 1 2 and a gear 2 3 are arranged in the base 1, and the gear 1 2 and the gear 2 3 are staggered and distributed, such as figure 1 As shown in the figure, the position height of the gear one 2 is higher than the position of the gear two 3, please refer to figure 2 At the same time, the diameter of the first gear 2 is smaller than the diameter of the second gear 3, and the transmission ratio can be changed by using the sizes of different gears, thereby realizing the deceleration function.

[0020] In this embodiment, the first gear 2 is sleeved on the shaft one 5, the position of the gear one 2 can be positioned by the shaft one 5, and the gear one 2 can be connected to the shaft one 5 At the same time, the top and bottom ends of the first shaft 5 are connected to the machine base 1 through the bearing end cover 8, and the position of the first shaft 5 can be determined by using the bearing end cover 8. , so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com