Automatic grease pumping and injecting device and method for bearing lubrication

A bearing lubrication and grease injection device technology, which is applied in the direction of lubricating oil input, lubricating pump, bearing components, etc., can solve the problems of bearing cavity temperature rise, seal leakage, insufficient amount of lubricating grease in the bearing cavity, etc., so as to ensure the safe reserve , to avoid sealing leakage, to ensure the effect of safe lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

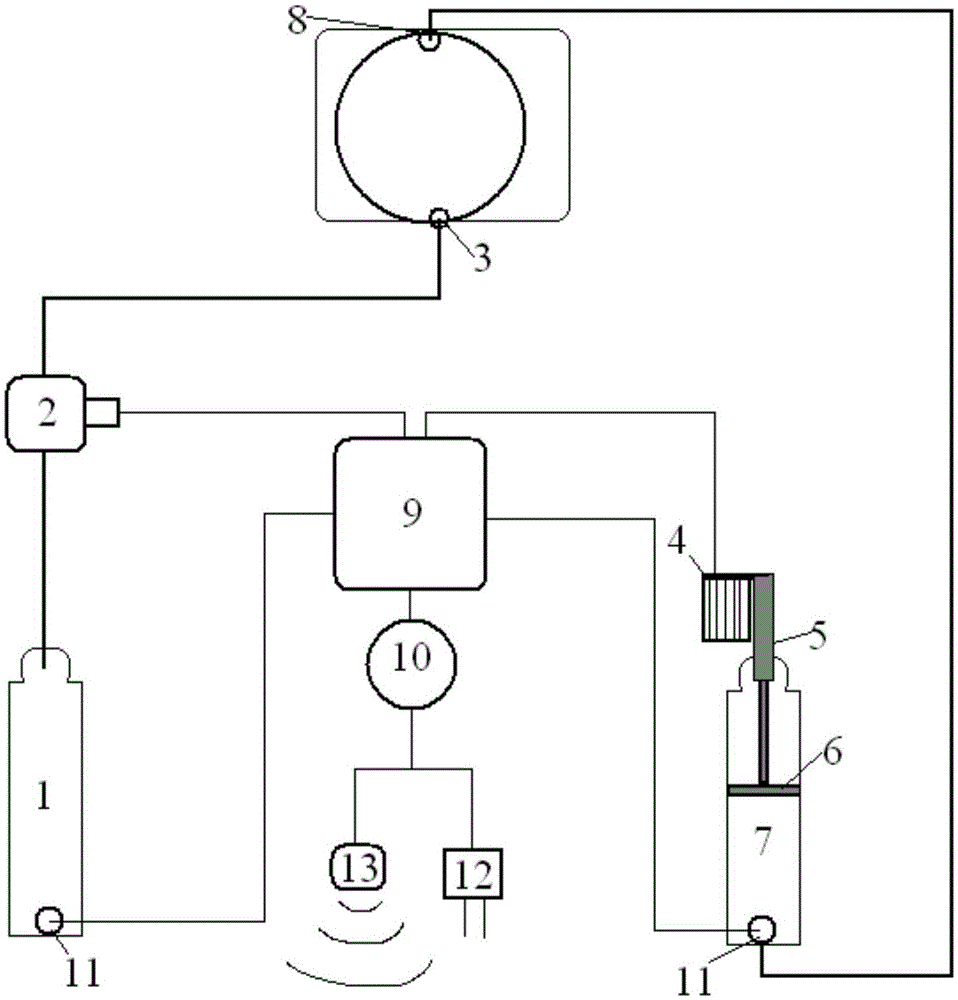

[0019] The structure of the automatic liposuction and grease injection device for bearing lubrication provided by the invention is as follows: figure 1 As shown, including control system, feedback system, liposuction system and fat injection system.

[0020] The liposuction system includes a waste fat storage tank 1, a liposuction pump 2, and pipes, valves, and joints. The liposuction pump 2 is connected to the fat discharge port 3 of the bearing chamber through pipes, joints, and valves, and the outlet of the liposuction pump is connected to the waste fat storage tank. In the same way, the waste grease in the bearing chamber is sucked out from the grease discharge port 3 under the action of the liposuction pump 2 and flows into the waste grease storage tank 1 . The liposuction pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com